Serviços Personalizados

Journal

Artigo

Indicadores

-

Citado por SciELO

Citado por SciELO -

Acessos

Acessos

Links relacionados

-

Similares em

SciELO

Similares em

SciELO

Compartilhar

Revista internacional de contaminación ambiental

versão impressa ISSN 0188-4999

Rev. Int. Contam. Ambient vol.23 no.2 Ciudad de México Abr./Jun. 2007

Cleaner production and innovation theory; social experiments as a new model to engage in cleaner production

Producción más limpia y teoría de la innovación; los experimentos sociales como un nuevo modelo participativo

Hans DIELEMAN

Erasmus University Rotterdam, The Netherlands, Universidad Autónoma Metropolitana, Unidad Azcapotzalco, Av. San Pablo 180, Col. Reynosa Tamaulipas, 02200 México, D. F. Phone: +52 55 5318 9062, Fax: +52 55 5394 7378. E–mail: Dieleman@fsw.eur.nl, webpage: www.artopie.info

Recibido marzo 2007

Aceptado mayo 2007

AbSTRACT

This paper discusses the concept of cleaner production and proposes a new model to stimulate cleaner production, in the first section the historical development of cleaner production is sketched. It is indicated that the approach gained much attention in the early ninety nineties, and generated an optimistic belief that cleaner production was soon to become a new practice within industry. In the second section the results of evaluation studies on cleaner production in Europe, USA, Australia and New Zealand are presented. These studies indicate that the rate of implementation of cleaner production is much slower than anticipated in the early ninety nineties. Section three presents various innovation theories. All of them help to explain why the rate of implementation is slower than anticipated, each pointing at slightly different aspects of cleaner production as an innovation. In section four the various theories are combined. It is explained how processes within companies are interrelated with institutional arrangements outside companies, such as legislation, education and knowledge transfer. Based on insights the combination theories it is proposed to organize social experiments to stimulate cleaner production. These social experiments can be considered as a third generation model to stimulate cleaner production, following the demonstration projects as the first generation and the regional network–based approach as the second generation. The social experiment is not to implement cleaner production in the narrow sense but to confront actors more fundamentally with the consequences of cleaner production for their own standards and ways of working. It adds the element of social change in order to create a comfortable socio–technical cleaner production network.

Key words: cleaner production, innovation, innovation theory, institutional learning, social experiments.

RESUMEN

Este artículo se refiere al concepto de producción más limpia y propone un nuevo modelo para estimularlo. En la primera sección se presenta el desarrollo histórico de la producción más limpia, se menciona cómo este enfoque llamó la atención a principios de los noventas, y generó una creencia optimista de que la producción más limpia pronto se convertiría en una nueva práctica dentro de la industria. En la segunda sección se presentan los resultados de los estudios de evaluación de la producción más limpia en Europa, EUA, Australia y Nueva Zelandia. Estos estudios indican que el índice de implementación de la producción más limpia fue mucho más lento de lo que se esperaba a principios de los noventa. La sección tres presenta varias teorías de la innovación. Todas ellas ayudan a explicar por qué el índice de implementación fue menor al esperado, también señalan diferentes aspectos de la producción más limpia. En la sección cuatro se combinan las diferentes teorías mencionadas. Se explica cómo están interrelacionados los procesos dentro de las empresas con las medidas institucionales fuera de ellas, tales como la legislación, la educación y la transferencia de conocimiento. Con base en las teorías combinadas se propone organizar experimentos sociales para estimular la producción más limpia. Estos experimentos sociales se pueden considerar como un modelo de tercera generación para promoverla, considerando los proyectos de demostración como la primera generación y el enfoque basado en redes regionales como la segunda generación. El experimento social no es para implementar la producción más limpia en un sentido limitado, sino para confrontar a los actores más profundamente con las consecuencias de la producción más limpia bajo sus propios estándares y bajo formas de trabajo. Agrega el elemento de cambio social con objeto de crear una red socio–técnica amigable de producción más limpia.

Palabras clave: producción más limpia, innovación, teoría de la innovación, aprendizaje institucional, experimentos sociales.

INTRODUCTION

Since the ninety eighties various approaches to reduce industrial environmental impact are developed. Most of these approaches are a response to the command–control legislation developed in the ninety seventies in the industrialized world. Central in the command–control legislative approach is the environmental permit. The permit "commanded" the industry to what levels the production of wastes and emissions was acceptable, and how environmental protection was to be organized within the firm to realize these levels. The environmental protection agencies were supposed to control if industries were complying with the content of the permits. The command–control approach started to be criticized for a number of reasons. First industrialists claimed that legislators were insufficiently capable of prescribing what protective measures they should apply. Secondly the permit system was very complex, as environmental legislation became more diversified and specialized to deal with various environmental media such as air, water and waste separately, every media asking for a separate permit. Thirdly only a small percentage of permits was accurate and effectively controlled and updated.

Industry responded by developing various systems and approaches that were "market–based" and "self–regulatory". The ISO management systems are probably the best–known response and everywhere in the world industries implemented systems to regulate themselves following the ISO–framework. Other approaches developed in the ninety eighties and ninety nineties are "Cleaner Production", "Life Cycle Assessment", "Eco–Design", "Industrial Ecology" and more recently "Socially Responsible Entrepreneur–ship" and "Sustainable Industrial Management".

This paper focuses on the developments of cleaner production: on its historical development and on a number of evaluation studies that were mainly carried out in the ninety nineties. The paper continues with analyzing the results of evaluation studies within the framework of innovation studies. The paper finishes with proposing a new approach to stimulate the implementation of cleaner production, based on the insights of innovation studies.

Cleaner production to reduce industrial environmental impact

Cleaner production is a specific approach to reduce industrial environmental impact. The origin of the approach is to be found in the American company 3M. In 1975 3M initiated its 3P–program: its "Pollution Prevention Pays" program. The philosophy of the program was that any waste produced during the production process is to be regarded as a misallocation of input materials. The 3M–3P–program was designed to work through the inputs of the employees. Employees were encouraged to report options that could reduce waste and emissions and could save money at the same time. The company promised that any option that would reduce costs would be implemented and the employee would receive a reward for reporting the option. In this way 3M was able to reduce considerable amounts of waste and considerable amounts of costs at the same time (Royston 1979).

Obviously the approach attracted attention from various sides. In 1984 3M was awarded with the World Environment Center's First Annual Gold Medal for International Corporate Environmental Achievements. In approximately the same period the Dupont–company decided to create a manual to facilitate its plant managers to engage in pollution prevention. This manual was designed for in–company usage and was adopted by the USA Environmental Protection Agency and published in 1988 as the Waste Minimization Opportunity Assessment Manual. Little by little cleaner production was accepted in the USA as a viable and effective approach. Interestingly the manual was not soon to be used in the USA, and its first and systematic usage was realized in Europe. The first proj ect was launched in Landskrona in Sweden, and the second and most comprehensive one in the Netherlands.

In 1989 two Dutch universities and the Dutch Organization of Technology Assessment engaged in a demonstration project to test the US/EPA Manual, and to develop a set of tools to facilitate industry, governments and consultants to use the 3P–approach. This project called PRISMA resulted in an improved version of the US–EPA manual and in various publications describing how the manual could be used (de Hoo et al. 1990, Dieleman et al. 1991). One year later UNEP started a cleaner production program using the methodology and experiences of the PRISMA–project. Since 1992 the United Nations Industrial Development Organization (UNIDO) and the United Nations Environment Programme (UNEP) has been disseminating the concept and the methodology worldwide. In various countries (especially in developing countries) UNEP established national cleaner production centers that have the objective to develop projects in various sectors of industry. Centers can be found in 24 countries, among which Brazil, Costa Rica, China, Ethiopia, India, México, Sri Lanka, Tanzania, Tunisia, South Africa and Vietnam.

The methodology used in cleaner production (CP) projects is centered on the identification and implementation of so–called cleaner production options or opportunities. The definition of cleaner production as used by UNEP reflects the essence of the methodology. The essence of the methodology is first of all to identify sources of the production of wastes and emissions inside the production process. Once such sources are identified the next step is to think about all possible ways to eliminate or reduce those sources. Once a variety of potential options is generated the methodology prescribes to engage in feasibility studies to assess the economic and environmental consequences of the options. Finally those options that prove to be feasible from an economic and a financial point of view are put forward for implementation. These subsequent steps can be characterized as (1) a planning and organization phase, (2) an assessment phase to identify wastes and emissions and options for change, (3) a feasibility analysis phase and (4) an implementation and continuation phase (Fig. 1)

At the end of the ninety eighties and the early ninety nineties cleaner production rapidly gained recognition worldwide. Various demonstration projects showed positive results and optimistic believe was to be found that Cleaner Production was soon to be applied on large scales in many industrial sectors.

Results of cleaner production demonstration projects

Since the mid of the ninety nineties it became little by little known that the optimism was somewhat premature. Various evaluation studies indicated that the implementation of cleaner production faced various barriers and was progressing rather slowly. These results are shown in various evaluation studies in all parts of the world (Table I).

In 1995 the Dutch research institute EIM conducted one of the first evaluation studies into the implementation of cleaner production (EIM 1995). The study showed that a majority of Dutch companies did not implement any CP–options in the period between 1990–1995. Almost simultaneously Bressers et al. concluded that only 40 % of the options generated in CP–projects were really implemented (Bressers et al. 1995). The results match with an evaluation study carried out in Graz in Austria to analyze Austrian ECO–PROFIT project 1997 (Breuer 1997). Based on a number of evaluation studies, De Bruijn et al. conclude in 1996 and 2000 that (especially smaller and medium sized) companies often lack the capabilities to implement CP–options. They make a plea for more collaboration and partnership (De Bruijn et al. 1996, 2000).

Dieleman devoted his PhD thesis to an evaluation of the PRISMA–project (Dieleman 1999). His thesis is a longitudinal in–depth study following 5 of the PRISMA–companies in the period of 1989 until 1996. He concluded that these 5 companies did implement less than 50 % of the options generated during the project. The reason was not that the companies conscientiously decided not to implement. The reason was much more that never a conscientious decision was taken to implement them. In order to understand this Dieleman focused on understanding the rationality of the economic behavior inside the companies. He matched the in–depth information of the 5 cases with results from the previously mentioned EIM–study and with various economic theories of rational behavior. His main conclusions were as follows. First of all decisions are very much influenced by random events: a letter from a legislator, a talk with a colleague, reading an article in a journal and so on. Economic behavior is not so very conscientious. People inside companies follow day–to–day developments and make decisions according to the influences they receive on a day–to–day basis. In making concrete choices they usually follow established routines and known ways of problem solving and try to avoid too much risk. It means that the day–to–day random influences are interpreted in the perspective of known ways of problem solving. When a stakeholder tells them to handle a certain environmental situation and they are experienced in pollution control, the decision will often be to invest in a pollution control, even when pollution prevention is actually paying and pollution control is not. He advises to focus less on "convincing" and "demonstrating" the benefits of cleaner production and to focus more on making cleaner production a normal part of day–to–day activities (Dieleman 1999 and Dieleman and Cramer 2004).

In 2002 Michael Overcash presents a review of USA based pollution prevention initiatives over the period of 1976 to 2001 (Overcash 2000). His overall conclusion is not over–optimistic. He makes a distinction between large, medium–sized and small industries.

He concludes that within large companies a fundamental and profound shift towards the use of pollution prevention has been made. Despite of that the implementation process is after 25 years only in the middle and significant opportunities remain. For medium–sized industries he concludes that industry representatives have been able to identify widely useful process and material changes. For the small companies he concludes that "progress through 2001 has been tentative" (Overcash 2002). This conclusion has important policy implications since, as Overcash is pointing out, most State and Federal Pollution Prevention Programs have been aimed at these small businesses. Apparently their effectiveness has not been very high. The US Pollution Prevention Round Table (2003) publishes an assessment of the 1990–2000 decade in a 2003 report.

The assessment was based on a nationwide survey. The Roundtable provides various numbers and mentions that many tons of pollutants have been prevented and much money is saved, but the report does not really put these numbers in perspective. It does conclude however that 70 % of the respondents said that they had a lack of resources to carry out their activities, and 40 % complained of the high rate of staff changes and lack of management commitment.

In 2003 New Zealand published a comprehensive evaluation study of its cleaner production initiatives (there labeled as Resource Stewardship and Waste Minimization) (Stone 2003). In order to stimulate implementation the country developed 2 strategic programs. The report concludes that many efforts have been taken in the seven sectors. What is missing however is a good institutional framework to make the strategies work more efficiently and especially ways to learn from previous experiences. Rene van Berkel concludes that cleaner production has developed into a comprehensive approach. Looking however at the situation in the Far East, notably in Australia and New Zealand, he observes that the approach remains "un– noticed to many in business, government and the community alike" (Van Berkel 2004).

The Project UNEP conducted a global evaluation at the turn of the century. The evaluation was carried out on a regional basis, distinguishing the different continents and key regions on several continents. The overall conclusion was that "Cleaner Production is underway in virtually all parts of the world. Progress is made and the concept itself is more and more getting integrated in other approaches. Despite the progress made in the last decade, the rate of implementation is slower than initially expected and much more still remains to be done for wide scale implementation of Cleaner Production" (UNEP 2002).

UNEP observed in its Cleaner Production Global Status Report (2002) that demonstration projects have a tendency to focus too much on the implementation of proven technological changes. To change this UNEP proposed that CP projects should focus more on systems and life cycle thinking, and should aim less at "technical retrofitting". To realize this new focus UNEP started to transform their regional Cleaner Production Centres into Strategic Business Units that have to identify region specific implementation strategies.

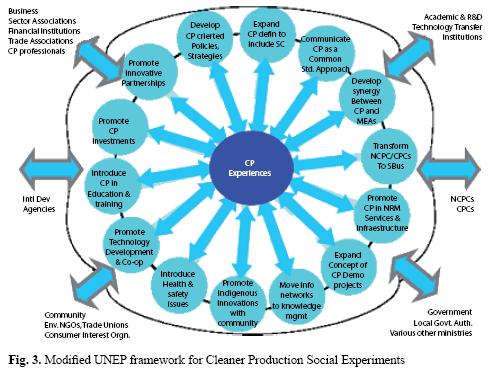

This new strategy aims to build strategic alliances to create favorable conditions for cleaner production implementation. The new strategic framework integrates most if not all of the key actions and actors needed to change successfully to cleaner production (Fig. 2). It distinguishes among four key groups of actors (business/industrial, academic/research, government and community), identifies what actions to take to stimulate cleaner production and links these actions to the four key groups of actors.

Many contemporary approaches to cleaner production work as sketched in the UNEP framework. They are often organized as regional projects involving various stakeholders in networks that work together to favor the implementation of Cleaner Production.

Explaining the results of cleaner production projects

Many reasons may be hold accountable for the rate of implementation of cleaner production. Some explanations used in the evaluation studies are "a lack of capabilities", "a lack of resources", "a lack of management commitment", and "a lack of an appropriate institutional framework". Some reasons focus on processes inside companies, others on the institutional environment around companies. Each of them can be looked at as reasonable explanations for the rate of implementation that is lower than initially expected.

The explanations are however partial. Some refer to characteristics of companies, other refer to the institutional framework around the companies. An obvious question is how the characteristics inside the companies and the characteristics of the institutional framework around the companies are related and mutually interdependent. Secondly the explanations are also rooted in various theoretical bodies of knowledge, which makes it more difficult to understand them in one comprehensive perspective.

That is why in this section innovation theory is used to frame the various explanations in a theoretical framework. A reason for using innovation theory is that this group of theories offers the possibility to focus more explicitly on the technological dimensions of the change process towards cleaner production. Innovation theory is at the same time a rich field or group of theories. It offers the opportunity to frame the previously mentioned explanations in a theoretical framework and gives at the same time some options to realize a more comprehensive explanation. Four perspectives will be presented. These perspectives all have slightly different views on the process of innovation and provide slightly different explanations. They can be considered to be complementary, each focusing on the innovation process from a different perspective.

Perspective 1: CP as a learning and change process in companies

A first perspective draws attention to the process of implementation of innovations in existing production processes. It is rooted in the work of Nathan Rosenberg and his books Inside the black box (1982) and Exploring the black box (1992). These works can be regarded as milestones in innovation theory (especially in the relation between technology and organization) and has been cited and used ever since they were released.

The key message in the books is that innovations in organizations need to be tailored to the specific characteristics of an organization in order to be successful and useful. With this message Rosenberg challenged the idea that the success of an innovation depends on the inherent features of the innovations. By contrast he shows that innovations are in the beginning far from being perfect and need various adaptations and modifications. The success of innovations largely depends on the extent to which they are successfully integrated into existing organizations. Rosenberg used two concepts to describe the process that is needed to integrate and tailor innovations: "learning by doing" and "learning by using". Learning by doing is a process to change and improve existing production technology. Learning by using is a process of integrating new technology in the existing production process.

According to Rosenberg innovation is a learning process, with the emphasis on both "learning" as well as on "process". Modifications of existing technologies and procedures inside organization take time. Almost never a change can be regarded as "accomplished" immediately. What is needed is experimentation that can answer questions like: is the innovation functioning as expected and anticipated? What additional modifications are needed to make the innovation performing as envisioned, in the existing production process, in the working procedures of workers operating with the innovation, anywhere else? Only by using new technologies the organization can learn how to use the innovation to its fullest potentials and to make it a successful innovation.

Rosenberg emphasizes that it is practically impossible to have answers to all of these questions when an innovation is developed on the drawing table. In practice and through experimentation it is possible to answer these questions. And while answering the questions the innovation gets integrated. And while the innovation gets integrated the organizations learn how to use the technology. This learning process is by necessity a process of learning by doing or using. Disregarding this learning process is looking at a company as a black box and a key aspect of innovation is overlooked: the process of learning. Rosenberg challenged consultants that advice companies to invest in new technologies (for instance cleaner technologies) without accompanying the implementation process. Innovation should be regarded as a process in which various levels of an organization need to learn through their involvement in the change process.

The work of Rosenberg is very relevant for cleaner production. As described in paragraph 2, cleaner production is a process in which product and process modifications are the outcome of a process of assessments, feasibility studies, experimentations and implementation. Cleaner production demonstration projects often initiate the heuristic search processes inside companies and end with a list of potentially feasible options. Usually it is up to the companies themselves to actually implement the options. These types of CP–projects usually start a process inside the companies and make assessments together with the representatives of a company. In these assessments the specific problems of a company are identified. In a next step the project develops and discusses with the company representatives various options for change. Subsequently some of the selected options are studied and evaluated for implementation. Experimentations and feasibility studies are an integral part of good CP–projects.

By applying this methodology it may look like the projects acknowledge the importance of the learning process inside companies and in fact to a certain level they do. But too often the crucial phase of the real implementation process is not a part of these CP–project. When Bressers, Breuer and Dieleman all find that less than 50% of all options generated are implemented (even after a period of 5 years in the case of the findings of Dieleman), the explanation is not necessarily a lack of commitment or resources, but the simple fact that implementation is a learning and change process that cannot be taken for granted but is too often not integrated in the CP demonstration projects, and especially not the first generation projects.

Perspective 2: CP hampered by a pollution control institutional framework

The second perspective draws on the evolutionary economic innovation studies of Richard Nelson, Sydney Winter and Giovanni Dosi, and the studies of Bengt–Åke Lundvall on the role of institutions in innovation processes. Nelson and Winter (1982) explain in their ground braking work An evolutionary theory of economic change how innovations develop along certain established technological trajectories within technological regimes. Dosi (1982) followed up on that work by enlarging the concept of a "technological trajectory" towards the concept of the paradigm, encompassing technology and institutions in basically one concept. Lundvall (1988) created the concept of "institutional trajectories" that are centered on the role of institutions in society.

Trajectories, regimes and paradigms are constructed around certain technological solutions or applications that have become standard and referential. A combustion engine for instance is a technology to generate power. Once this technology is applied in certain specific ways like the engine of a car, innovations usually focus on the improvement of that technology. Potential alternative technologies that can generate power in different ways are easily ignored or overlooked. As a result innovation is often path–dependent. A trajectory results in routines and in the accumulation of expertise in a certain perspective. This perspective is highly influencing and canalizing subsequent search processes. This explains for instance why so much effort is put in the past decades in making the existing combustion engine cleaner and more full efficient, and so much less effort is put in developing an alternative engine based on for instance hydrogen and the fuel cell. Dosi (1982) places some more emphasize on the role of institutions in the development of regimes. Little by little it is not any longer the research–community that thinks similarly along certain pathways, but other institutions in society follow and adapt themselves to the dominant technology. Within the example of the combustion engine it means for instance that legislation centers primarily on that type of engine. The amount of tax is based on the number of cylinders and/or the cubic centimeters inside the engine. Environmental legislation focuses on emission standards for this type of engines, and so on. Lundvall emphasizes how institutions in general have a tendency to focus on their own preservation and how this complicates the switch from one technological perspective towards another. As a result societies can get "locked in" certain trajectories or regimes and the development and application of alternative approaches is limited and slowed down.

Some of the reported explanations for the slower rate of implementation refer to the institutional environment of cleaner production. De Bruijn et al. (1996) made a plea for more collaboration and partnership while Stone (2004) was pointing at the lack of an appropriate institutional framework to facilitate and stimulate cleaner production. Hofman (2003) and Dieleman (1999) looked more closely at cleaner production from this point of view, and identified the existence of a pollution control regime. A pollution control regime exists when the standard approach in treating industrial pollution is to apply end–of–pipe treatment technology and when most major institutions have got locked in this standard way of dealing with waste and emissions. Dieleman (1999) concludes that many CP–projects in essence prove that a pollution control regime exists. When a demonstration project can identify many CP–options it is an indication that companies are not seeing existing pollution prevention opportunities. They are "blind" for pollution prevention since solutions for waste and emissions are almost immediately phrased in terms of end–of–pipe and treatment technologies. The big achievement of many CP–projects is that they open the minds of industrialists. The projects make them see the possibilities of an alternative approach. The success of many pollution prevention demonstration projects is exactly here: they demonstrate the possibilities and feasibility of a preventative approach that is often overlooked.

It is important that CP–projects recognize the dynamics of pollution control regimes. This means that they have to complement their actions inside companies with at least two additional activities: first involve most of the major stakeholders of a company in the project; and second work with the company and its stakeholders over a considerable amount of time. The reason to work with the stakeholder is the following. A regime not only exists inside companies but is to be found in the institutional environment of the companies as well. And this is exactly the reason why the implementation of options is hampered and the continuation of cleaner production in companies is often lacking: the institutional environment is not cooperative and can be counter productive. Suppliers of new technologies, consultants, research organizations, education and governments all are partners in the choices for certain solution of environmental problems. When most of these partners are trained in pollution control instead of pollution prevention, they will advice and sometimes even prescribe companies to invest in treatment technology. In order to build up a new standard approach in a new regime it is necessary to work with the institutional environment over a considerable amount of time, so new routines and new heuristic search processes can establish themselves and become a self–evident new standard. Many contemporary CP–projects are in fact working more closely with the relevant stakeholders to involve them in the change towards cleaner production.

When CP–projects do not acknowledge the dynamics of pollution control regimes and trajectories it is more than likely that the effect of one CP–project is limited in scope and in time.

Perspective 3: CP as an innovation–diffusion process

The third perspective draws on the work of Everett Rogers (1995). Rogers is the father of the idea of innovation diffusion. In his work that spans the period of 1962 to 1995 he studied hundreds of innovation processes. One of Rogers' findings is that many of these processes follow an S–curve. At first the innovation–diffusion rate is slow. After some time the innovation diffusion process accelerates and in a subsequent phase the adoption and diffusion rate slows down again. What happens is that at first a small group of innovators engage in new technologies or new practices, followed by a group of early adopters that is slightly bigger but still small. An innovation really diffuses when the majority of people starts to use it. Rogers makes a distinction between an early and a late majority as two groups with slightly different characteristics. Relevant is that when these two groups decide to accept an innovation it becomes really accepted in a group or a society. Finally there is a group of "laggards" that refuse to accept the innovation for a long time and sometimes as long as possible. A safety belt or the practices of separate collection of waste are examples of innovations that follow quite ideal–typically this pattern. They are accepted with enthusiasm by a few and only later more collectively accepted by larger groups. Some people however continue to refuse to wear a safety belt or to engage in the separation of wastes, even though it has become a new standard in a certain community.

Unless the other scholars discussed in this article, Rogers does not approach innovation as a search process. Consequently he is less concerned with explaining the rate of diffusion and adoption by pointing at the characteristics of the search process. Rogers pays much attention to the role of change agents in the innovation diffusion process. Mass media can function as change agent, and so can government, consultants, and heroes like singers or football players. Rogers points out that mass media play important roles in many innovation processes. Continued and targeted information in general is very influential in getting a majority accepting an innovation.

The work of Rogers is hardly ever applied to explain the rate of implementation of cleaner production. Yet it potentially bears some interesting insights. A first observation based on the innovation–diffusion body of knowledge is that the pattern of diffusion of cleaner production is quit archetypical or "normal". When almost all innovations follow the same pattern there is no reason to assume that it should be different for cleaner production. It is not at all unreasonable to assume that the first generation CP–projects have reached the group of the early adopters. The challenge is now to reach the group of the majority. Following Rogers this means finding the proper change agent(s) to accelerate the rate of diffusion of cleaner production.

It is reasonable to assume that these change agents need to have a certain authority and legitimacy. Governments, legislators and branch organizations could play an important role in stimulating cleaner production, not only by means of participating in CP–projects (as is one of the recommendations within the previous perspective 2), but also as change agent and as protagonist of the cleaner production approach. As Boons et al. (2000) observe, cleaner production is until now mainly a bottom–up approach based on the execution of demonstration projects. The assumption in these projects is that due to the inherent positive features of cleaner production ("it pays") the diffusion would follow more or less automatically. This proves to be not the reality. The influence of appropriate change agents may be needed to bring cleaner production to a next level of diffusion.

Perspective 4: CP as a process of building new socio–technical networks

Perspective 4 draws on the work of the sociologists Bruno Latour (1987), Michel Callon (1987), Wiebe Bijker and John Law (1992). The key assumption in this perspective is the idea of the social construction of technology. The assumption challenges the idea of technological determinism in which humans have to adopt themselves to technological progress that is autonomous and inevitable. Studies in this perspective focus on the concept of "socio–technology". Callon and Latour, founders of the so–called Parisian school in the sociology of innovations, have developed this concept into a very specific direction that is provocative but yet widely accepted.

For Callon and Latour innovation is not a process of inventing, modifying or applying new technology. By contrast it is a process in which people and technologies mutually adapt to each other. And because of that they both change, more or less at the same time. Technology and humans "translate" each other and in this process of 'translation' they both change to become better suited to each other. At least two of the implications of this theory are relevant for cleaner production, one on a micro–scale and one on a network–level.

The first implication (on micro–scale) refers to the actual translation process of humans and technology. To explain some relevant characteristics of this process Latour, like Rosenberg, uses the term "black box". Yet he applies this concept in a completely different way. In his terminology "blackboxing" is a verb and an activity to make the translation between humans and technology successful. A translation is "blackboxed" (and the innovation successful) when it generates no problems or discomfort and is perceived as a new self–evident and logical reality.

This concept is relevant since cleaner production options are often not blackboxed. As a result workers in companies do not feel comfortable with the options and the level of acceptance is low. An example may help to illustrate this. A Dutch environmental regulator prescribed a metal processing company to invest in an air–filter to reduce the concentrations of solvents to the air. The CP–project in which the company was involved by contrast advised to switch from solvent–based paint to water–based paint. In doing so the investment in a filter could be avoided and other advantages could be realized, such as better working conditions. The companies' environmental engineer was hesitant however as changing to water–based paint implied that the workers needed to be trained in using this new paint. As an environmental engineer he was experienced and comfortable in managing environmental data and managing treatment technologies. He had no experience in training his colleagues and supervising them in the new working procedures of using water–based paint. He did not feel comfortable at all in engaging in this new role. The option was not blackboxed and the environmental engineer postponed the change towards water–based paint as long as possible. In the end the switch to water–based paint was not realized.

This example illustrates that implementation of options is more than technical change. It implies that people have to redefine their roles, responsibilities, their relationships with existing technologies, with other people and eventually redefine themselves. When CP–projects do not sufficiently take this process of mutual adaptation and blackboxing into consideration the implementation of an option can easily fail.

More or less the same processes can be observed on the level of networks of people and organizations. Latour refers in this respect to the process of building socio–technical networks. Here as well translation is a central mechanism. On the level of networks humans and technologies interact to find new ways of co–existing together (translation). In such a process various actors redefine each other and themselves. When this results in blackboxing a new socio–technical network is born with a new socio–technical practice. Also this notion has important implications for cleaner production. Usually the cleaner production approach is not consistent with the traditional ways of working of legislators and permit givers. This can very well explain why the environmental management approach is more easily accepted among legislators. The environmental management approach is oriented towards providing environmental information with much less emphasis on improving or changing production processes. In that sense the approach is more suited to the traditional regulatory practice and routines of permit givers and inspectors. They feel more comfortable judging provided information than judging whether a production process can be significantly improved or not (see: Boons et al. 2000).

These sociological and socio–psychological aspects hold strong explanatory powers for understanding why cleaner production implementation–rates are lower than initially expected.

Interrelating the different perspectives

The four perspectives presented in section 4 are based on various innovation theories, and focus on particular aspects of innovation processes. They can be considered as being complementary to each other. At the same time these perspectives in innovation theory coincide very well with the various phases in the cleaner production methodology: the assessment, the generation of options for change, the feasibility studies, the implementation of the options and the repetition the process.

The first steps in cleaner production are the assessment and the search processes for options and solutions. Perspective 2 of section 4 explains why these search processes are heuristic search processes. They are based on expectations: one searches for certain solutions because one has experience from the past that certain solutions will be found in certain areas. The challenge of cleaner production is that it tries to change heuristics. It tells industries to no longer look for end–of–pipe treatment technologies, but to start to look inside the production processes. Obviously industries have initially little expectations and need some guidance to carry out the new search procedures. One of the characteristics of CP–projects is that they provide companies with guidance and faith. A next step is to generate options and to do feasibility studies. The dynamics in these steps are well explained by perspective 1: it is a matter of trial and error and of learning by doing. As more sector specific studies were published during the ninety nineties this part of the projects became a little bit more easy to accomplish. That is why the first 3 steps usually can be accomplished during CP–projects.

The subsequent step is the implementation process. As the evaluation studies showed, the implementation of options often lacks behind the expectations. Perspective 1 shows why the cleaner production feasibility studies are in essence studies. They may provide enough ground to make a go/no–go decision, but it does not mean that the options are easily "implemented". Perspective 1 is clearly showing why and holds strong explanatory power. Yet, perspective 2, the existence of a technological regime in the institutional environment, is relevant here as well. The perspective shows the importance of the institutional environment of companies, and shows that innovation in companies is a matter of collaboration of various stakeholders and actors. Therefore it is essential to involve these stakeholders in cleaner production projects. This is clearly represented in the new UNEP framework.

And this is happening more and more often. One of the important changes in cleaner production is the increased involvement of stakeholders in the projects. In the literature dealing with the topic of environment and industry (cleaner production, environmental management, industrial ecology, life cycle approach, etc.) a consensus can be found that much more attention should be given to the business environment of companies, and that the major stakeholders of companies should be involved in the cleaner production change processes (cf. Phillips et al. 1999, Dieleman 1999, Ashton et al. 2002, UNEP 2002, Dieleman and Cramer 2004 and Baas 2005). That is why contemporary approaches do involve stakeholders much more, often organized in regional network–based projects. Specifically with the context of promoting cleaner production, the United Kingdom has some 75 Waste Minimization Clubs since the early ninety nineties. These clubs involve various regional actors in waste minimization demonstration projects (cf. Phillips et al. 1999). Canada has a similar initiative, called Enviroclub. The city of Rotterdam in the Netherlands had for many years its Sustain–ability Club. In this club, initiated by the Erasmus University of Rotterdam, industry, government and academia worked together to develop strategies and practical sustainable projects for the Rotterdam region (Baas 2005). Many other regional initiatives to promote cleaner production can be added to these examples. To a larger or smaller extent, these clubs and initiatives work together to complement each other in providing the necessary actions, information and conditions to favor the implementation of cleaner production.

This is a major improvement but is potentially also a source of new problems. When the stakeholders and the institutional environment work within a pollution control regime, they will not support cleaner production. In this scenario, a network–based approach can make the implementation more difficult. Then, the situation for workers outside companies is like the situation of those inside companies. They all will have little experience and know–how of cleaner production, and they all, consultants, researchers, regulators and suppliers alike, will need to learn to work within the new regime of cleaner production. Perspective 1 and perspective 2 are really complementary in their explanation of the rates of implementation of cleaner production.

Perspective 4 of section 4 describes quite similar processes with other concepts, and offers some practical ways to change the situation. It emphasizes that an innovation process is not only a process of implementation of new options. It is at the same time a process in which people and technologies translate each other and form new socio–technical networks. The so–called implementation process should not be called implementation process but translation process as this word is more accurately covering the reality. Not only production process technology needs to be changed, but in this process humans need to redefine themselves as well. Perspective 4 is adding additional information to the image sketched on the basis of perspectives 1 and 2 and can be considered as complementary to those two perspectives as well. The three perspectives together show the importance of the implementation or "translation". And as this phase is often not integrated in CP–projects it provides a powerful explanation for the disappointing rates of implementation as shown in the evaluation studies.

The final step in the cleaner production methodology is the step of repeating the process. Most of the evaluation studies pay little attention to this part of cleaner production. Dieleman (1999) did ask companies if they had repeated the process and if they had generated new options. The answers indicated that no new options were generated in the five years after the completion of the projects.

Various mechanisms can stimulate a repetition of the process. Positive feedback coming from the projects is one reason why companies may want to decide to do a new round of assessments and option generation. Stimulation or pressure coming from actors around the companies is another mechanism to stimulate a repetition of the process. Since major change agents holding authority and credibility such as legislators and consultants do not contribute to diffuse the approach on larger scales (perspective 3 of section 4) there is apparently not sufficient impetus to repeat the process. This is relevant for companies that participated in CP–projects and for potential new companies not yet involved in the methodology. This may explain why the approach remains unnoticed to many in businesses and in government, as van Berkel observes to be the reality in Australia.

In a concluding way the four perspectives present various explanations for understanding the dynamics of cleaner production projects. Perspective 3 sheds light on the dissemination of the concept through promotion and publicity. The other three perspectives focus more directly on the process of changing companies and their business environments. The lesson to be learned, combining the perspectives 1, 2 and 4, is that (1) the changes towards cleaner production are of a "learning–by–doing" nature and involve experimentation, that (2) companies and their business environments both need to be involved in the experimentations and that (4) when cleaner production is a rupture with traditional ways of working and traditional ways of problem solving, processes of "translation" are needed for all actors involved.

Towards social experiments to promote cleaner production

The lessons we can learn from innovation theory are to a certain extent incorporated in more contemporary cleaner production projects. This is especially true for the involvement of various networks of stakeholders in the projects. A next step is to find ways to incorporate the combination of the lessons in cleaner production projects. This means combining at the same time (1) involving networks, (2) experimenting and learning by doing and (3) translating networks and actors within the new cleaner production way of working.

This section explores a model that can incorporate the combined lessons of innovation theory. The model is that of social experiments, that can be regarded as third generation cleaner production projects. The first generation model to promote cleaner production was the demonstration project. The second generation is the more contemporary regional network–based approach, involving various relevant stakeholders. The social experiment, the third generation, is even broader in scope than the regional network–based approach. The social experiment model does involve stakeholders and translate these stakeholders within the cleaner production way of working. The aim is to blackbox an entire network of actors within a cleaner production way of working.

The starting point and initial question is: what is needed to make companies engage in cleaner production in an ongoing way? Obviously the first answer is that companies need to engage in assessments of their own production processes and products. They need to explore possibilities to change, generate options and see if those options can be implemented. This all is consistent with the way the first generation cleaner production projects were organized. From this point on however, the model changes.

In addition to focusing on economic, technical and environmental feasibility, the questions to be asked and assessments to be carried out focus on the ways of working of people, both within and outside the companies. The focus will be on existing ways of communication, existing responsibilities and existing levels of knowledge and capacities inside and around companies.

Questions to be raised are among others: what does cleaner production, and a number of concrete changes in the production process, mean for an environmental manager in a company? And what does it mean for a responsible of a product line? Does the communication need to be organized in different ways and if so, how? What changes does it involve for the roles that all of these people play? It is important to know if workers can be comfortable in their revised ways of working with new roles and new responsibilities. It is, in other words, important to know what processes of translation are necessary to blackbox a new cleaner production ways of working. Do workers have to redefine themselves and each other? Does it mean that they have to acquire new knowledge, new skills or new values and are they capable and willing to engage in that?

The same questions are relevant for basically all the actors around companies. What does cleaner production (and some very concrete changes in production processes) mean for a legislator, a permit giver and controller? What does it means for consultants and researchers, especially when they are specialized in treatment technology and end–of–pipe solutions? Here again it is important to know what processes of translation are necessary to blackbox the new cleaner production ways of working. The question is not only what is needed but also if the stakeholders will be capable of making those changes and if they are willing to make those changes.

The idea of the social experiment is not to answer the above stated questions in generic senses. The idea is to raise these questions for specific cleaner production options that are put forward. And the answers depend very much on the specific technical, organizational and financial impact the options will have for specific companies. And these impacts are dependent on the specific places where companies are located: continents, countries, regions, cities, industrial parks, etc. On the basis of the specific technical, organizational and financial contexts, the potential consequences for people involved can be identified. As a consequence these questions are case specific and can only be really answered while cleaner production projects enroll, including their implementation. These questions (and their answers) are important parts of a learning–by–doing and learning–by–using process in which initial innovations and options are modified and tailored to specific circumstances.

The social experiments are like Gestalt–therapy: they are targeted at practical change and at practicing and experimenting with new attitudes, routines and new definitions of ones self and others. For instance: what does it mean for a company to change from solvent–based paint to water based paint, as was the issue in the example mentioned in section 4.4. of this article? In that example the company did not implement this change, as the companies' environmental engineer did not feel comfortable with his new role of training colleagues. To prevent this problem it is important to blackbox the option and to ensure that people are feeling comfortable. Various options are open. The first one is to train the environmental engineer. It is important to not only to train this person in terms of knowledge of water–based paint. It is important to train him or her as well in terms of teaching and communication capabilities. And here the aspect of social experiment really becomes manifest. It is important to practice with the new capabilities. It involves organizing sessions to practice, for instance by doing role–plays in which the person involved can practice with the new role, new responsibilities and new ways of communication and collaboration. These new roles involve communication with people inside as well as outside a company. Therefore people from inside as well as outside the company needs to be involved in the training sessions, in the role–plays and possibly other games that enable to practice with the new tasks, new roles and new reality. Indeed, games and role–plays can be an important part of the practice, since they offer good possibilities to simulate and experiment with a new social reality (Dieleman and Huisingh 2006).

Another (complementary) option is to engage professional schools and environmental engineering universities in this change and stimulate changes in the curricula. And here again, it is not a matter of proposing these changes to the educational institutes, but to execute them in experimental ways so teachers and schools can change and translate themselves in this new reality. Sometimes changes in curricula will be minor, but in situation where for instance a switch from purely engineering towards interdisciplinary education is needed, the consequences for educational institutions can be considerable and difficult to realize. Here once more experimenting, organizing classes in an experimental way, evaluating the results and little by little adapting to a new reality may be involved (Dieleman and Juárez 2007).

In principle every option embodies a potential range of translation–questions that can basically only be explored by engaging in their execution, by doing and through learning from practice. Enlarging the cleaner production approach with the perspective of translation and with the incorporation of social experiments can help to overcome the identified shortcomings in the approach: the lack of implementation of options, the lack of repeating the process and the lack of larger scale recognition.

The framework as developed by UNEP is a good starting point since it involves various actors and various activities. What needs to be added is the aspect of translation and feedback and of flows of information and reflections. These go from concrete cleaner production experiences to governments, communities and academia and vice versa. These can influence as well activities such as the development of CP–oriented policies and strategies or the promotion of CP–investments. Feedback and feed–forward loops should be added to the framework, in basically going in all directions. This is represented in figure 3, the modified UNEP framework for cleaner production social experiments.

Obviously social experiments are broader in scope than traditional demonstration projects and contemporary regional network–based projects. The social experiment is not to implement cleaner production in the narrow sense but to confront actors more fundamentally with the consequences of cleaner production for their own standards and ways of working. It adds the element of social change and organizational change. The aim is to change standards in ways of handling the environmental aspects of production through of mutual translation of the actors and the production processes. In this way a new cleaner production practice can be blackboxed and be a new logical and normal practice. This is the added value of the social experiment compared to traditional models to promote cleaner production.

CONCLUSIONS

In this article various aspects of cleaner production as a specific approach to reduce industrial pollution were presented and analyzed. The article started with an introduction of the concept of cleaner production, and presented the results of demonstration projects that were based on the standard and globally accepted cleaner production methodology. The first conclusion is that the results of most demonstration projects are disappointing, as many of these projects do not manage to have a real impact on the companies involved in the projects.

The article continued to present four theoretical explanations, based on four groups of innovation theories. The article concludes that all presented theories are relevant to understand the results of the demonstration projects, and identify several shortcomings of the demonstrations projects. The article also concludes that the various theories only present partial explanations that are linked to a particular phase of the cleaner production projects.

The article continues with the introduction of societal experiments as a new approach to promote cleaner production. These social experiments can overcome in a comprehensive way most of the identified shortcomings of demonstration project. In social experiments, various stakeholders in and around companies work together to stimulate cleaner production through networks, clusters or chains. This is rather similar to more contemporary approaches to stimulate cleaner production. Yet, the social experiment is not the same as the currently often–used approaches.

The aim of social experiment is not only to implement cleaner production in the narrow sense; the aim is to confront stakeholders with the consequences for their standards and ways of working. An essential element is the feedback on the routines, knowledge and conventions of the stakeholders. The question is, in what ways the stakeholders need to change in order to facilitate cleaner production. The feedback cannot take place in the form of a desk–study, as cleaner production is a process of learning by doing in real time. That is why experiments are needed in which practical changes are combined with simulations, role–plays, games and organizational feedback. That is why the article proposes social experiments as a new approach to promote cleaner production.

REFERENCES

Argyris C. and Schön D.A. (1996). Organisational learning II; Theory, method, and practice. Addison–Wesley. Reading Massachusetts. [ Links ]

Arthur W.B. (1988). Competing technologies: an overview. In: Technical change and economic theory (G. Dosi, C. Freeman, Nelson R.R., G. Silverberg and L. Soete, Eds.). Pinter Publishers. London/New York, p. 609–607. [ Links ]

Ashton Weslynne A.L. and Ehrenfeld J.R. (2002). Best practices in cleaner production promotion and implementation for smaller enterprises. School of Forestry and Environmental Studies, Yale University New Haven, CT, USA. [ Links ]

Baas L. (2005). Cleaner production and industrial ecology; dynamic aspects of the introduction and dissemination of new concepts in industrial practice. Doctoral Thesis Erasmus University Rotterdam, Eburon Academic Publishers, Delft, The Netherlands. [ Links ]

Bassanini A.P. and Dosi G. (2001). When and How Chance and Human Will Can Twist the Arms of Clio: An Essay on Path–Dependence in a World of Irreversibilities. In: Path Dependence and Creation (Garud, R. and P. Karnoe, eds.). Lawrence Erlbaum Associates. London, pp. 41–68. [ Links ]

Berkel R. van (2006). Cleaner production and eco–efficiency In: Handbook on Environmental Technology Management (D. Marinova, Ed.). Edward Elgar Publications, Cheltenham, UK. [ Links ]

Bijker W. and Law J. (Eds.) (1992). Shaping Technology / Building Society: Studies in Sociotechnical Change, MIT Press. Cambrigde, MA. [ Links ]

Boons F., Baas L., Bouma J., De Groene A. and Le Blansch K. (2000). The Changing Nature of Business, International Books, Utrecht. [ Links ]

Bressers J.Th.A., de Bruijn T.J.N.M., Coenen F.H.J.M., Lulofs K.R.D. and Marquart N.E. (1995). Onderzoek naar proefprojectenafvalpreventie; (Analysis of pilot–projects wasteprevention), VROM report 1995/20–a The Hague. [ Links ]

Breuer C. (1997). Ecoprofit Graz– The city council's ambitions versus industrial needs. Graz: EAEME/Umweltambt der Stadt Graz, 1997. [ Links ]

Bruijn de T.J.N.M., Coenen F.H.J.M. and Lulofs K.R.D. (1996). Pollution Prevention Projects in the Netherlands, Journal of Cleaner Production 4, 41–53. [ Links ]

Bruijn de T.J.N.M. and Hofman P.S. (2000). Pollution prevention and industrial transformation: evoking structural changes within companies. Journal of Cleaner Production 8, 215–223. [ Links ]

Callon M. (1987). Society in the Making: The study of technology as a tool for sociological analyses. In: The Social Construction of Technological Systems (W.E. Bijker, Th. P. Hughes and T. Pinch, Eds.). Cambridge Mass. MIT–Press 1987, pp. 83–103. [ Links ]

Cohen W.M. and Levinthal D.A. (1990). Absorptive capacity: a new perspective on learning and innovation. Administrative Science Quarterly 35, 128–152. [ Links ]

Dieleman H., van Berkel R., Reijenga F., de Hoo S., Brezet H., Cramer J. and Schot J. (1991). Kiezen voor preventie is winnen, naar een preventief milieubeleid voor bedrijf en overheid (To choose for prevention is to win, towards a preventative environmental policy for industry and government, NOTA, SDU Den Haag, Netherlands. [ Links ]

Dieleman H. and de Hoo S. (1993). Toward a tailor–made process of pollution prevention and cleaner production: results and implications of the prisma project. In: Environmental Strategies for Industry (K. Fischer and J. Schot, Eds.). Washington, DC, Island Press. pp. 245–275. [ Links ]

Dieleman H. (1999). De arena van schonere productie; Mens en organisatie tussen behoud en verandering. Eburon, Delft. [ Links ]

Dieleman H. and Cramer J. (2004). Strategies to implement cleaner production: towards a systems approach. Erasmus Centre for Sustainability and Management, Erasmus University Rotterdam. [ Links ]

Dieleman H. and Huisingh D. (2006). The potentials of games in learning and teaching about sustainable development. Journal of Cleaner Production (Special Issue on Education for Sustainable Development) 14, numbers 9–11. [ Links ]

Dieleman H. (2006). Cleaner Production and Innovation Theory; How the practice of Cleaner Production can benefit from theories on innovation. Conference Proceedings III International Symposium on Engineering and Sciences for Environmental Sustainability, Universidad Autónoma Metropolitana–Azcapotzalco 6 – 10 June 2006. [ Links ]

Dieleman H. and Juarez M. (2007). Interdivisional course in sustainable development and interdisciplinary thinking; new initiative at UAM–Azcapotzalco in México. Paper presented at the International Advanced Research Workshop on Higher Education for Sustainable Development (HESD), March 29–30, 2007, Maribor, Slovenia. [ Links ]

Dosi G. (1982). Technological paradigms and technological trajectories: a suggested interpretation of the determinants and directions of technical change, Research Policy, 11, 147–162. [ Links ]

Dosi G. (1983). Technical change and industrial transformation: the theory and an application to the semiconductor industry. London, McMillan Press Ltd, 198 p. [ Links ]

Dosi G. (1988). Sources; procedures and micro–economic effects of innovation. Journal of Economic Literature, 26, 1120–1171. [ Links ]

EIM/Milieu (1995). Afvalpreventie bij bedrijfsmatige activiteiten, preventie–informatie vraag en aanbod; een kwantitatief onderzoek bij bedrijven en intermediaire organisaties, (Waste prevention in industrial activities, a quantitative analysis in companies and intermediary organizations) Zoetermeer the Netherlands. [ Links ]

Ehrenfeld, J.R. (1994). Industrial Ecology and Design for Environment: The Role of Universities. In: The Greening of Industrial Ecosystems (B.R. Allenby and D.J. Richards, Eds.). Washington D.C. Natural Academy Press, pp. 228–241. [ Links ]

Hofman P.S. (2003). Embedding "Radical" Innovations in Society. Background Report to the CondEcol Project based on Experience from the Netherlands. Program for Research and Documentation for a Sustainable Society (ProSus). Centre for Development and the Environment, University of Oslo. [ Links ]

Hoo de S., Brezet H., Crul M. and Dieleman H. (1990). Handleiding voor preventie van afval en emissies (Manual for the prevention of waste and emissions), NOTA SDU Den Haag the Netherlands. [ Links ]

Latour B. (1987). Science in Action. How to Follow Scientists and Engineers Through Society. Cambridge MA., Harvard University Press. [ Links ]

Lundvall B.A. (Ed.) (1988). National systems of innovation; towards a theory of innovation and interactive learning. London, Pinter Publishers. [ Links ]

Nelson R.R. and Winter S.G. (1982). An evolutionary theory of economic change. Cambridge Massachusetts, Belknap Press of Harvard University Press. [ Links ]

Overcash M. (2002). The evolution of US pollution prevention, 1976–2001: a unique chemical engineering contribution to the environment – a review. J. Chem. Tech. Biotech. 77, 1197–1205. [ Links ]

Phillips P.S., Read A.D., Green A.E. and Bates M.P. (1999). UK waste minimisation clubs. A contribution to sustainable waste management. Resources, Conservation and Recycling 27, 217–247. [ Links ]

Rogers E.M. (1995). Diffusion of innovation. 4th edition., New York. The Free Press. [ Links ]

Rosenberg N. (1982). Inside the Black Box: Technology and Economics, Cambridge, Cambridge University Press. [ Links ]

Rosenberg N. (1994). Exploring the black–box: Technology, economics and history, Cambridge, Cambridge University Press. [ Links ]

Stone L. (Ed.) (2004). Resource Stewardship and Waste Minimization; towards a sustainable New Zealand University of Canterbury, Centre for Advanced Engineering, Christchurch New Zealand. [ Links ]

UNEP (2002). Cleaner Production Global Status Report, Paris, UNEP. [ Links ]

US/EPA (1988). Waste Minimization Opportunity Assessment Manual, United States Environmental Protection Agency, Cincinnati USA, Report EPA 625/7–88/003. [ Links ]

US National Pollution Prevention Roundtable (2003). An Ounce of Pollution Prevention is Worth Over 167 Billon Pounds of Cure: A Decade of Pollution Prevention Results 1990–2000. NPPR, January 2003. [ Links ]