Introduction

Soil compaction is regarded as the most serious environmental problem caused by conventional agriculture (McGarry, 2001). The overuse of wheeled farm machinery reduces pore space, resulting in dense soil with poor internal drainage and reduced aeration, which leads to increased soil strength that particularly impedes root growth (Moullart, 1998; Bayhan et al., 2002; Hamza and Anderson, 2005). Most of the common operations used in intensive cropping (tilling, harvesting, spreading chemicals fertilizers) are performed by heavy wheeled machines. According to Tullberg (1990), more than 30% of the ground area is trafficked by the tires of heavy machinery even in genuine zero tillage systems (one pass at sowing). Under minimum tillage (two-three passes), the percentage is likely to exceed 60%, and in conventional tillage (multiple passes), the percentage would exceed 100% during one cropping cycle (Soane et al., 1982). In spite of these circumstances, the problem of soil compaction by wheeled farm machine traffic has not been well documented in Mexico, nor specifically in the Vertisol soil characteristic of the maize producing area of the Toluca-Atlacomulco Valley.

Soil compaction is the most difficult type of degradation to identify and rationalize because no evident marks may show on the soil surface. Unlike erosion and salinization, which create strong surface evidence of degradation, finding evidence of soil compaction, its extent, nature and cause, requires physical monitoring and examination (Hamza and Anderson, 2005). Most available knowledge on the effects of soil compaction induced by machinery traffic has been acquired from field experiments (Håkansson et al., 1988; Voorhees, 1992). Such effects on soil properties are complex (Batey, 1990). The degree of compaction is an important soil structure attribute, and the most frequently used parameter to characterize compaction is dry soil bulk density (Panayiotopoulos et al., 1994). Soil strength is also used as a measure of soil compaction because soil strength reflects soil resistance to root penetration (Panayiotopoulos et al., 1994; Tardieu, 1994; Hamza and Anderson, 2003).

Sampling soil to quantify compaction and other soil physical conditions is frequently destructive, and therefore, generally considered impractical. Instead, laboratory experiments have been performed to analyze the response of the soil to machinery traffic by using confined uniaxial compression tests (Dawidowski and Lerink, 1990; O´Sullivan, 1992; Sánchez-Girón et al., 1998). In this type of test, confining stress is not particularly important because the compaction process is essentially governed by the normal stresses applied by the supporting elements of the agricultural equipment rather than by the confining stress of the soil in the ground (Koolen, 1987). The double-cycle uniaxial compression test, also known as texture profile analysis in food research, has been widely employed to determine mechanical properties of different materials. Using a universal testing machine, the main advantage of this test is that it offers the possibility of obtaining data from a single, quick test for several variables such as hardness, cohesiveness, adhesiveness and elasticity, among others (Gasca-Mancera and Casas-Alencáster, 2007). Although, at the time of this writing, this method has not been reported to evaluate soil's physical properties, further testing has compared and validated its results with penetrometer measurements and conventional adhesiveness tests of similar Vertisol soil samples.

The objective of this research was to use double-cycle uniaxial compression, penetration resistance and cutting force tests using a universal testing machine to evaluate the response of a Vertisol soil in terms of hardness, cohesiveness and adhesiveness when compacted by wheel traffic in different types of tillage systems.

Materials and methods

Soil samples were obtained from three tillage systems established on a 0.25 ha area of the experimental field of the School of Agricultural Sciences at the Autonomous University of the State of Mexico, in Toluca, State of Mexico, Mexico (19° 24' 43'' N, 99° 41' 40'' W, 2609 m.a.s.l.) during May 2011. The soil was classified, according to the USDA Soil Taxonomy System, as a Vertisol, suborder Uderts, great group Pelluderts and subgroup Entic Pelluderts. The experimental area has been used for wheat, oats and maize rotation under conventional tillage for more than 10 years. Three different tillage systems were established on the site during 2008 to study the effects of tillage and other production techniques on maize cultivars and soil and water quality.

The study included the following tillage systems and traffic applications:

Conventional tillage (CT): multiple passes with a disc plow (model 635, two-wheel drive tractor, John Deere 5715), harrowing, sowing and fertilization combined and hoeing; 0% stover.

Minimum tillage (MT): five passes, one with a multi-plow (model M-250, using a four-wheel drive tractor, John Deere 6603), three passes of harrowing and one of sowing and fertilization combined (two-line sowing implement, Sembradora del Bajío); 30% stover.

Zero tillage (ZT): one pass comprising sowing and fertilization (two-wheel drive tractor, John Deere 5715); 100% stover.

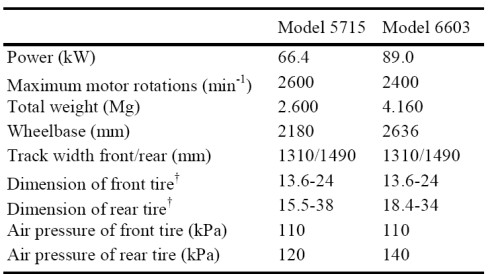

Some specifications of the tractors used for the agricultural operations are provided in Table 1. The experimental design consisted of a randomized complete block arrangement with three replications of the tillage systems, resulting in nine plots of 12.8 × 10 m including 16 rows 0.8 m apart; plots were separated by an 8 m wide traffic maneuvering area. A single hybrid maize cultivar (Zea mays L., cv. Aspros (r) AS-722) was sown in all experimental plots, under a twin-line arrangement and rain-fed conditions. Seeding density was 50 kg·ha-1 with inter-plant distance of 0.15 m. Fertilizing for all systems was NPK at a rate of 120-60-30 units applied at sowing.

Table 1 Technical specifications of the John Deere(tm) tractors used in the experiment.

† Dimension according to SAE nomenclature standard J751, 1997.

For all systems, soil samples were obtained from the topsoil (0-150 mm) and subsoil (150-300 mm) horizons before tillage operations to evaluate bulk density (BD, g cm-3) and total organic matter content (TOM, %). The BD was determined using the method proposed by Landeros and Serrato (2001); TOM was estimated using the AS-07 test (NOM-021-SEMARNAT-2000, 2002).

The soil samples for the double-cycle uniaxial compression test (DUC) were obtained after the hoeing operation from the topsoil level (0-150 mm) using a Soil Core Sampler (50 × 150 mm, 2" × 6" model Signature Series, AMS, Inc., American Falls, Idaho, USA) in the wheel track of each system plot (inter-rows). After sampling, the soil samples were tested on an as-is basis using a Universal Testing Machine (Stable Micro Systems TAX-T2, Stable Micro Systems Ltd., Godalming, Surray, United Kingdom) with a 25 kg charge cell, adapting the method originally proposed by Gasca-Mancera and Casas-Alencáster (2007) for food samples. The values for hardness (N), adhesiveness (N s-1) and cohesiveness were obtained by performing two compression cycles of 2 mm depth (1.3% of apparent relative deformation related to the original height), using a cylindrical acrylic probe 12.7 mm in diameter at a speed of 7 mm s-1.

To measure penetration resistance (Pr), soil samples were obtained from the topsoil (0-150 mm) and subsoil (150-300 mm) horizons using the Soil Core Sampler in the wheel track of each tillage system plot (inter-rows) after the hoeing operation. The device used as a test probe in the universal testing machine was a Phillips (r) screwdriver 6.3 mm in diameter, 186.01 mm2 contact surface and 150 mm stem length. Samples, after collection, were subjected to one 50 mm compression cycle at an assay speed of 7 mm s-1, with the results expressed in MPa. Soil samples for the cutting force test (Cf) were obtained using the Soil Core Sampler from the subsoil horizon (150-300 mm) of each tillage system plot after the hoeing operation. The probe used for the Cf test consisted of a straight-type screwdriver (model DR-5/16x6BP, Truper Herramientas, México) with a 7.9 mm diameter and a 150 mm stem length. The sample containers were cut in half at one tip (50 mm cut length, 25 mm wide) to allow measurement of the uniaxial component only and were disposed horizontally to simulate the action of a γ-angle two-face wedge. The samples were subjected to one compression cycle of 25 mm at an assay speed of 1.4 mm s-1, with the results expressed in N and joules (J) for the cutting work. Soil samples of all tillage systems were evaluated for moisture (M, gravimetric %), according to the method proposed by Landeros and Serrato (2001), before laboratory mechanical tests.

The obtained data were statistically analyzed by an analysis of variance (ANOVA) using SAS software (Statistical Analysis System, USA). All of the parameters were analyzed with a minimum of three repetitions and tested for significance (P < 0.05) between the systems. When significant differences were found, the Tukey test was used to determine the differences between means.

Results and discussion

Soil Properties of Experimental Site

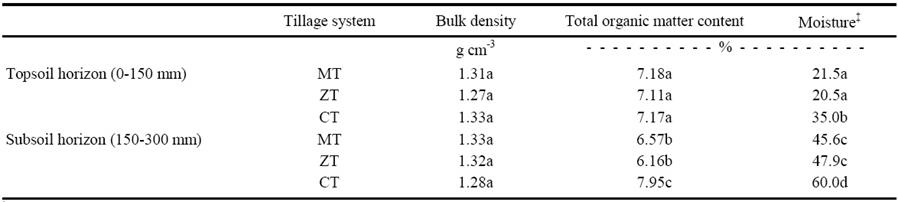

Bulk density (BD) values before tillage operations were similar in all of the tillage systems and at both depth levels (Table 2). Similar topsoil contents of the TOM were also found for all the systems. At the subsoil level, CT reported the highest TOM value of the three systems, with an average content increment of 25% relative to the other two systems (Table 2). The values obtained for BD were slightly higher than those reported by Casado and Valencia (2004) for a representative soil horizon of the experimental field and were indicative of similar soil compaction levels throughout the entire experimental area as a result of continued use of conventional tillage. Similar topsoil contents of TOM in the three tillage systems showed that since the establishment of MT and ZT in the experimental area (two years), the use of the multi-plow in the MT system did not efficiently incorporate the corn stover of the 2009 and 2010 crop cycles at different depths. In the ZT plots, the stover remained on the surface as mulch. TOM was found to be higher in the CT subsoil than in the subsoil of the other systems due to the incorporation of organic matter from the previous crop cycle by primary tillage operation with a disc plow.

Table 2 Soil properties for minimum tillage (MT), zero tillage (ZT) and conventional tillage (CT) plots of the experimental area†.

† Each value is the average of at least three observations; means in the same column followed by different letters are significantly different (P < 0.05) by the Tukey test. ‡ Sampled before mechanical testing.

The moisture (M) at the topsoil level after hoeing was found to be higher in CT than in the other systems (62% higher on average), and CT also reported the highest value at the subsoil level (27% higher on average) (Table 2). The highest M value of CT in the topsoil and subsoil horizons could be explained by lower water infiltration speeds, and consequently higher water retention, in a relatively weak soil structure caused by the tillage activity. Further testing, measuring mean infiltration speed in the tillage systems, corroborated this assumption. This confirms the results reported by Hamza and Anderson (2002; 2003), where the water infiltrates uncompacted soils much faster than massive, structure-less soils.

Double-cycle Uniaxial Compression Test

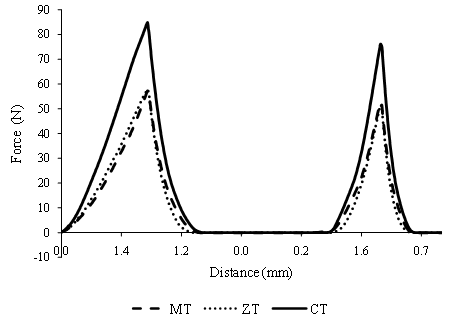

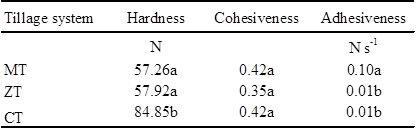

CT was found to increase soil hardness in the DUC test (Figure 1). The values for soil hardness were lower in MT and ZT than in CT and were statistically similar between MT and ZT (Table 3). The shape of the DUC curves revealed a similar soil structure for the three systems, with lower cohesiveness values for ZT (Table 3). Although MT reported the highest adhesiveness values, none of the systems showed significant values for adhesiveness due to the lower soil moisture content (Table 3). The higher hardness values reported for CT in comparison with the other tillage systems confirm the results of Dickson and Ritchie (1993), who compared zero and reduced ground pressure traffic systems with a conventional traffic system.

Figure 1 Double-cycle uniaxial compression curves for minimum tillage (MT), zero tillage (ZT) and conventional tillage (CT) systems at 1.3% of the apparent relative deformation.

Table 3 Some physical property values of Vertisol topsoil (0-150 mm) of three different tillage systems under the double-cycle uniaxial compression test†.

† Each value is the average of nine observations; means within the same column followed by different letters are significantly different (P < 0.05, Tukey). MT = minimum tillage; ZT = zero tillage; CT = conventional tillage.

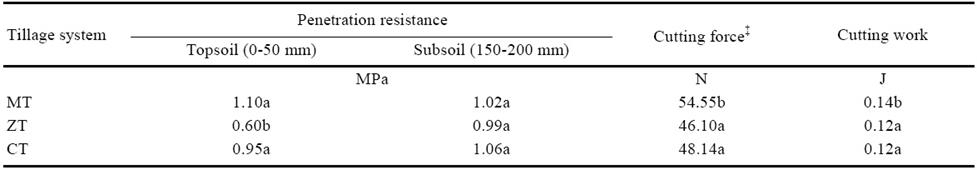

According to Gasca-Mancera and Casas-Alencáster (2007), the ARD level used may have influenced the manifestation of hardness, and this effect could explain the differences and the lack of correlation with the results of the penetration resistance (Pr) test (Table 4). Although no statistically significant differences were found among the tillage systems for cohesiveness, numerically lower values for ZT could reflect poorer topsoil aggregate stability due to lower organic residue content and insufficient re-wetting (Radford et al., 2007), which could lead to higher soil resistance to root penetration (Narro, 1994). MT reported the highest adhesiveness, but because soil moisture content was lower than 60%, none of the systems showed relevant adhesiveness values. MT's adhesiveness could be related to slightly lower water content in the test samples compared with the other systems, Ortiz-Cañavate and Hernanz (1989) sustain that adhesiveness is drastically heightened with small decrements in water content.

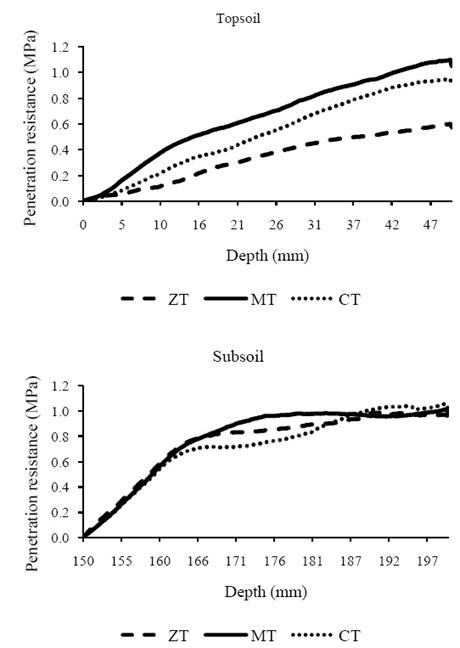

Penetration Resistance

The subsoil maximum Pr values obtained for ZT were significantly higher than the values of the topsoil level (Table 4). For the first 50 mm of the topsoil horizon, MT was found to increase penetration resistance (Figure 3), with reported values slightly higher than those of CT (Table 4). This could be explained by the use of multi-plow equipment which produces less fragmentation of the topsoil than the disc plow. At the subsoil level, with higher moisture content than the soil surface, Pr behavior was similar for all systems (Figure 2). Higher Pr values in the subsoil compared with those in the topsoil level are not consistent with the values reported by Botta et al., (2008), who showed that the pressure exerted by tractor passes results in a greater increase of topsoil cone index values (as a measure of soil strength) compared to the subsoil levels.

Table 4 Maximum values of some soil physical properties of the different tillage systems' plots†.

† Each value is the average of nine observations; the means within the columns followed by different letters are significantly different (P < 0.05, Tukey) MT = minimum tillage; ZT = zero tillage; CT = conventional tillage. ‡ Means of maximum cutting force values at subsoil level (150 mm) for each treatment.

Cutting Force

Figure 3 shows the cutting force (Cf) curves of 25 mm of displacement in a horizontal plane of the subsoil horizon (150-300 mm) for the different tillage systems. For the MT system, the Cf average numerical value obtained at the end of the test is higher than the probe's initial impulsion force curve, which is a revealing aspect of the system's wedge effect at increasing distance, and was significantly higher (by 16% on average) than the two other systems (P < 0.05). The maximum values for ZT were not significantly different from those for the CT system for the distance range (25 mm) of the evaluated subsoil horizon (Table 4). The form of the obtained Cf curves agrees with the results obtained by Vincent (1991) in the way that the shapes typically reflect the forms associated with the wedge fracture assay, showing an initial peak at the impulsion of the cutting instrument, followed by a merely constant force in the rupture propagation ahead of the wedge. The higher maximum value obtained at the end of this test for MT could also be explained by the multi-plow, which produces greater subsoil fragmentation than the disc plow, thus producing higher compaction levels at this level with subsequent wheel traffic passes compared with other tillage systems.

Conclusions

The following conclusions can be made based on the results obtained with the experimental conditions proposed in this study:

The double-cycle uniaxial compression tests proved sensitive enough to detect differences in hardness, cohesiveness (numerical), and adhesiveness of soil samples of the different tillage systems.

The pressure exerted by the amount of wheeled traffic passes did not cause a linear increase in soil compaction at the topsoil level in a Vertisol, according to the Pr tests accomplished in the universal testing machine.

Subsequent wheel passes on fragmented subsoil after multi-plow use at minimal tillage slightly increased subsoil compaction, according to the Cf and Pr tests.

The benefits of multi-plow use in reducing soil compaction during this period (two years) could not be detected by any of the assay methods used in this experiment.

nueva página del texto (beta)

nueva página del texto (beta)