Introduction

Several biological materials attract attention due to the unique mechanical resistance properties and singular structures that they present, even though they are constituted for the most part by minerals, which when considered in isolation, can present great fragility (Chen et al., 2008). However, when associated with organic matrices, they form hybrid composites of a ceramic and a biopolymer with microarchitecturally different sections and structures highly organized with extraordinary mechanical properties as those found in mollusks shells (Sarikaya & Aksay, 1992; Graham & Sarikaya, 2000; Lin et al., 2006; Chen et al., 2008; Heinemann, 2011).

Shells are remarkable structures of biological origin, with unique shapes and designs, and for some mollusks, properties such as superior fracture resistance, flexural strength and hardness (Currey & Taylor, 1974; Cortie et al., 2006; Shojaei et al., 2012). Such hard exoskeleton has great importance for animals living in tropical and humid environments, even though they are made up of thin structures, provide support and protection against predators, mechanical damage, dehydration and hydrostatic pressure (Furuhashi et al., 2009; Francis, 2012; Watanabe et al., 2015; Morii et al., 2016).

Many organisms, among them mollusks, have developed sophisticated strategies to direct the growth of the inorganic constituents of their mineralized matter, resulting in improvements in mechanical properties. Many researchers study this characteristic in order to apply the same biomineralization strategies in synthetic materials development as composite materials and materials for medical applications (Volkmer, 2000; dePaula et al., 2010; Putro et al., 2014; Yao et al., 2015). In this context, the genus Pomacea Perry, 1810, considered the largest group of freshwater gastropods, with approximately 20 species registered for the Amazon Region, among them Pomacea dolioides (Reeve, 1856) (Simone, 2006), is considered important in the development of new composite materials.

The gastropods of the genus Pomacea have already been studied for various aspects, antipredator behavior (Ueshima & Yusa, 2014), temperature effects on the shells (Yoshida et al., 2013; Bae & Park, 2015) the environment effects on shell shapes (Estebenet & Martín, 2003) effects of its introduction into other environments (Rawlings et al., 2007; Horgan et al., 2014) reproduction (Estoy Jr et al., 2002; Barnes et al., 2008; Wu et al., 2011) and its behavior in Amazon floodplain areas (Watanabe et al., 2015; Fonseca et al., 2017). However, even a shell being a structure of extreme importance for maintaining the animal life in its natural habitat, it was not found information regarding the behavior of this genus shells when subjected to mechanical stresses resulting from natural impacts, predator attacks and other abrasive effects of the environment.

The present study aimed to analyze the mechanical behavior of P. dolioides (Reeve, 1856), seeking to characterize the mechanical properties that confer protection to the mollusk. The resistance to the three-point bending is directly related to the load supported by the shell until the fracture, while the hardness may be related to the shell resistance to the wear provided by the environment and may present variations in the different shell layers due to the porosity, presence of organic phase and microstructural characteristics. The surface roughness of the shell, can provide information of the capacity of sliding of the animal in the shell and also of the inter-lamellar sliding of the microstructure, due to the nano-asperities present in the crystals microconstituents (Graham & Sarikaya, 2000; Evans et al., 2001; Wang et al., 2001; Liang et al., 2008; Yang et al., 2011; Lv et al., 2015; Liang et al., 2016).

Materials and methods

Shells used. In order to perform all the experiments described, one hundred empty shells of P. dolioides of different sizes were collected from a floodplain area located in Itacoatiara (AM), Brazil (03°08’24.50” S, 58°27’24.60” W), in the mid Amazon region, between June and August 2016. The shells were washed in running water with detergent, dried and kept at room temperature during the experiments. The Mollusca Collection of the Oswaldo Cruz Institute (CMIOC) carried out the specie identification, with the register number CMIOC 10552: Pomacea dolioides (Reeve, 1856).

Bending test

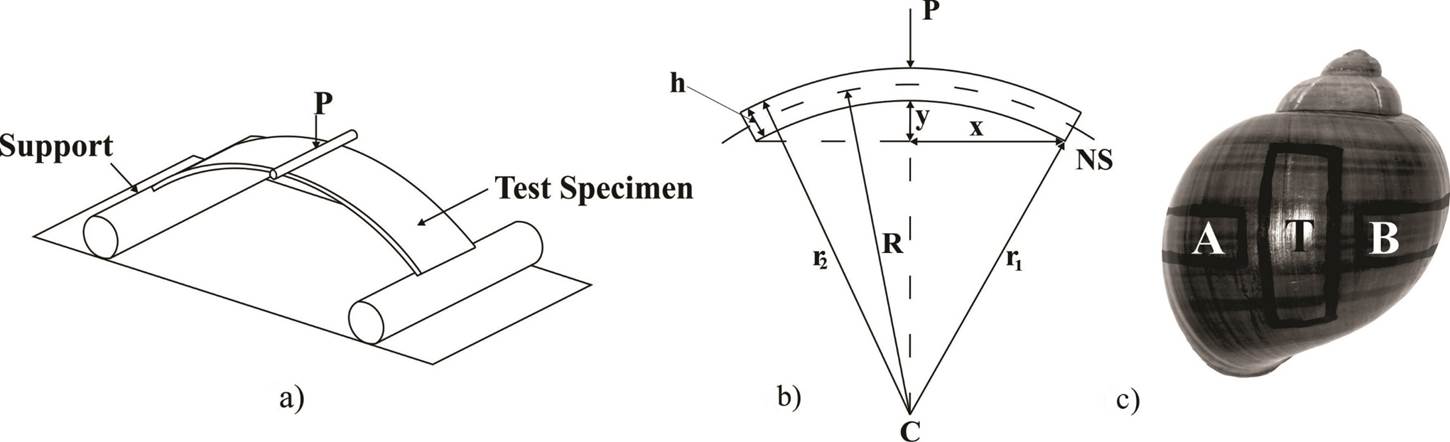

In order to analyze the strength of P. dolioides shells, a three-point bending test was carried out with some shells specimens. The method consists of applying a load (P) in the central area of a standardized specimen supported at its ends, thus generating flexion, as shown in Figure 1 a) and b).

Figure 1 a) Illustration showing the specimen with two points of support and a load application point. b) Representation of the curved specimen, showing its center of curvature (C) Neutral surface (NS), applied load (P) and distances: R, r 1 , r 2 , y, h e x. c) Shell of P. dolioides, showing positions A, T and B from where the specimens were withdrawn.

Tests were carried out in compliance with the American Society for Testing Materials (ASTM) C1161-13 for ceramic materials; however, some adjustments in the test were necessary due to the impossibility to withdraw specimens in straight prism format rectangles. The test was performed at room temperature, with a distance between supports of x = 40.0 mm (x = 20.00 mm).

Only shells larger than 40 mm could be used in bending tests, since the small shells were not large enough for the extraction of test specimens with adequate dimensions for the test.

Specimens for the bending test were taken from three different shell positions: next to the open and transversal direction (ID: A), central area and longitudinal direction (ID: T) and opposite area and cross direction (ID: B), as shown in Figure 1 c). The specimens were cut from the shell using a disc and measured using a caliper rule Digimess. The mean width (W m ) and the mean thickness (h m ) were obtained by the arithmetic mean of five points measured along the specimen.

The calculation of the flexural strength of the shell material was performed using two methods: the first one calculates the Flexural Rupture Module (MOR) using Equation 1, where (P) is the maximum load applied to the specimen until its rupture and (x) is the arm of the bending moment, distance from the application of the load to the bearing, as described in Technical Standard ASTM C1161-13. The second method used to calculate the flexural strength sought to correct the effects of the shell curvature in the calculation of the MOR described by Technical Standard ASTM C1161-13, since the specimens of the P. dolioides should be treated as a curved beam, not as a prism recto rectangle.

The second method proposed in this work aims to obtain the tensile stress (σ t ), maximum stress on the lower surface of the specimen in the region of load application, and the compression stress (σ c ), minimum (negative) stress on the upper surface of the specimens in the region of load application, using Equations 2 and 3, respectively, in which the specimen curvature is considered. In Equations 2 and 3, the bending moment (M) was obtained through Equation 4, the mean radius (r m ) was calculated by means of the arithmetic mean of the internal (r 1 ) and external (r 2 ) rays, Equation 5, the radius (R) from the Center of Curvature (C) to the Neutral Surface (NS) was obtained using Equation 6, where (A) is the cross-sectional area of the specimen. And for the calculation of (r 2 ), we used Equation 7.

The geometric relationship between parameters (x), (y) and (r 1 ) shown in Figure 1 (b) was necessary and it was obtained through the Pythagorean Theorem, as shown in Equation 8.

Rockwell Surface Hardness Test. The hardness test was carried out using a Digimess Rockwell durometer, model 400.001 (MSM). The Rockwell Superficial hardness scale 15N (HR15N) was used with a diamond indenter with 3.00 kgf preloading and a 15.00 kgf main load. Forty (40) tests on shells with four (4) different sizes were performed. The specimens analyzed were cut with a circular cutting disc.

Roughness Test. In order to assess the roughness level of the inner layer of the P. dolioides shells, the test was carried out using an Instrutherm Digital Surface Roughness Tester RP-200. The parameters calculated through this mechanical test followed the standard method of the International Organization for Standardization (ISO) standard ISO 4287, considering a 0.25 mm Cut off and a Cut off number equal to 5; an RC ripple filter, a ± 40 µm Range, a 5 µm diamond needle tip radius, and a 4 mN applied force. To perform the roughness test and optical microscopy (Lumen NIM-100), samples whose internal surface was fairly flat were chosen. The samples used did not undergo any kind of surface treatment, were only washed, dried and kept at room temperature.

Due to the sensitivity of the rugosimeter, it was only possible to perform the test on the inner surface of the shell with no apparent signs of wear since the surfaces that were heavily worn by the environment or the external surface of the shell presented roughness levels outside the scale of the equipment.

Results

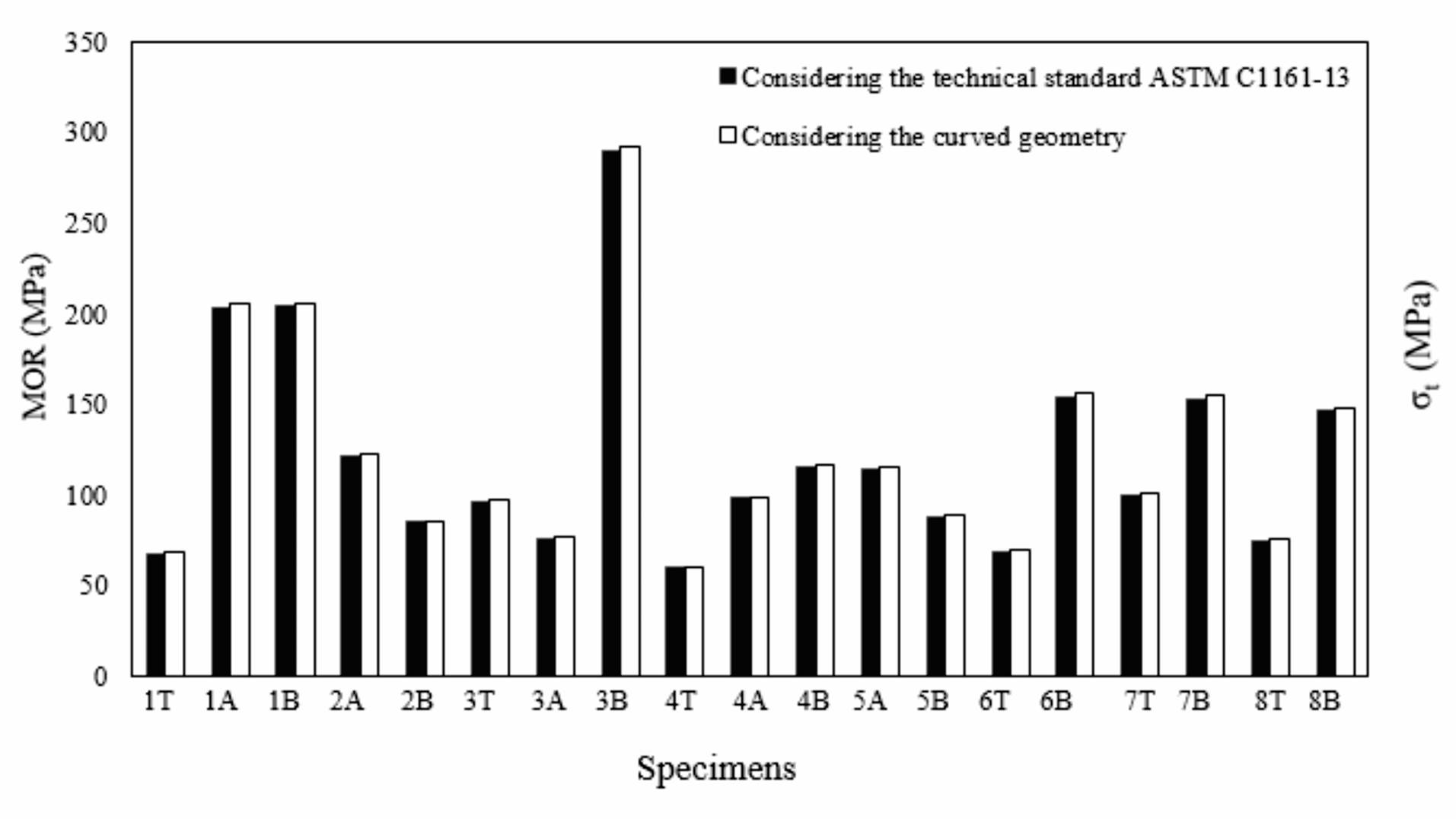

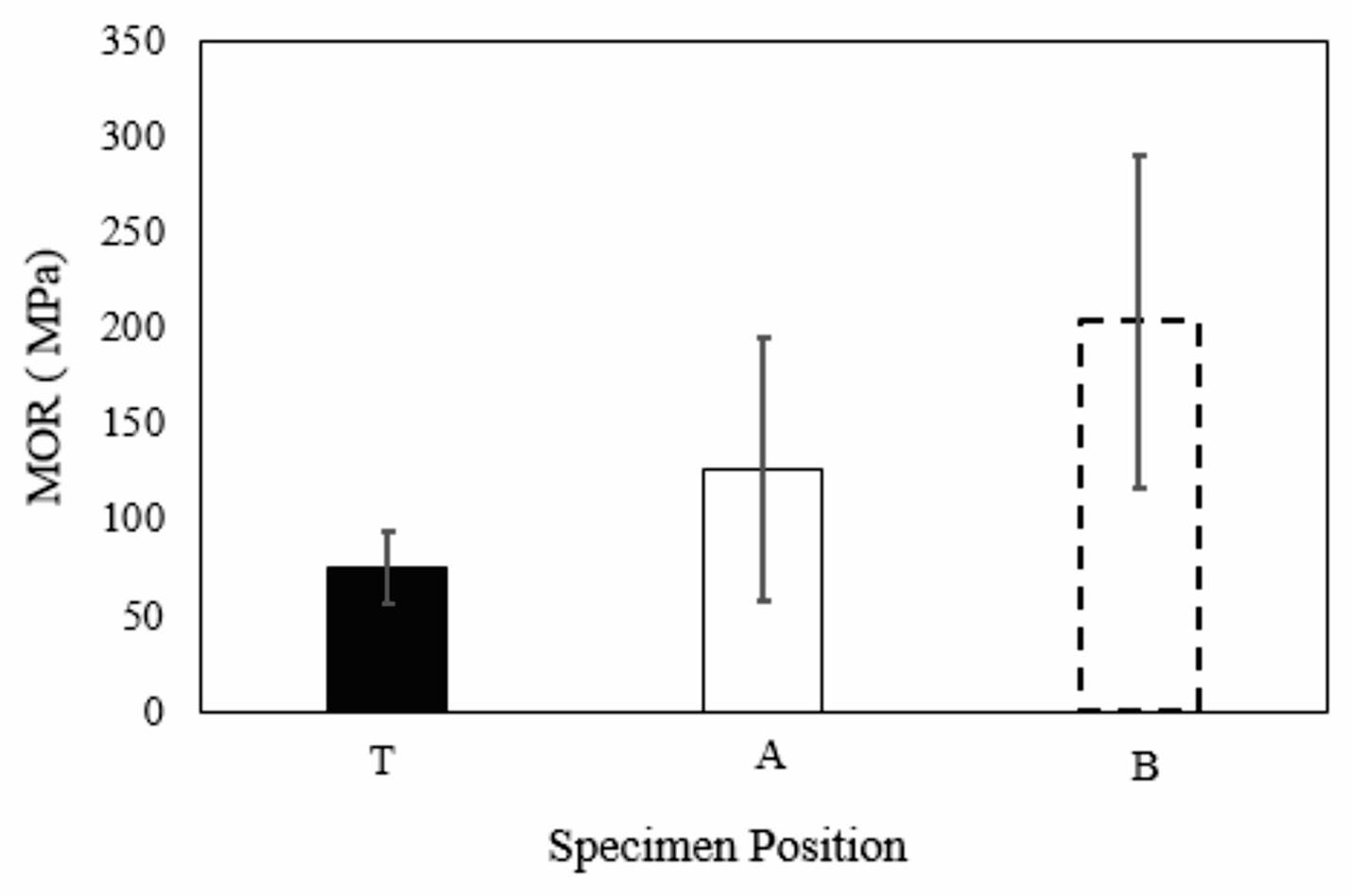

Bending test. The results of the bending test of P. dolioides shells are presented in Figure 2, showing the flexural rupture modulus (MOR) according to ASTM C1161-13 (black columns) and maximum tensile strength (σt) on the lower surface of the specimen following a proposed methodology correcting the effects of the curved geometry (blank columns). A slight difference between two methodologies is observed, in which the effect of the curved geometry provides a slight increase in the flexural strength of specimens extracted from the shell.

Figure 2 Flexural rupture modulus (MOR) for different test specimens taken from positions A, T and B, following the ASTM C1161-13 (black columns) and maximum tensile strength (σt) on the lower surface of the specimen considering the influence of curved geometry (blank columns).

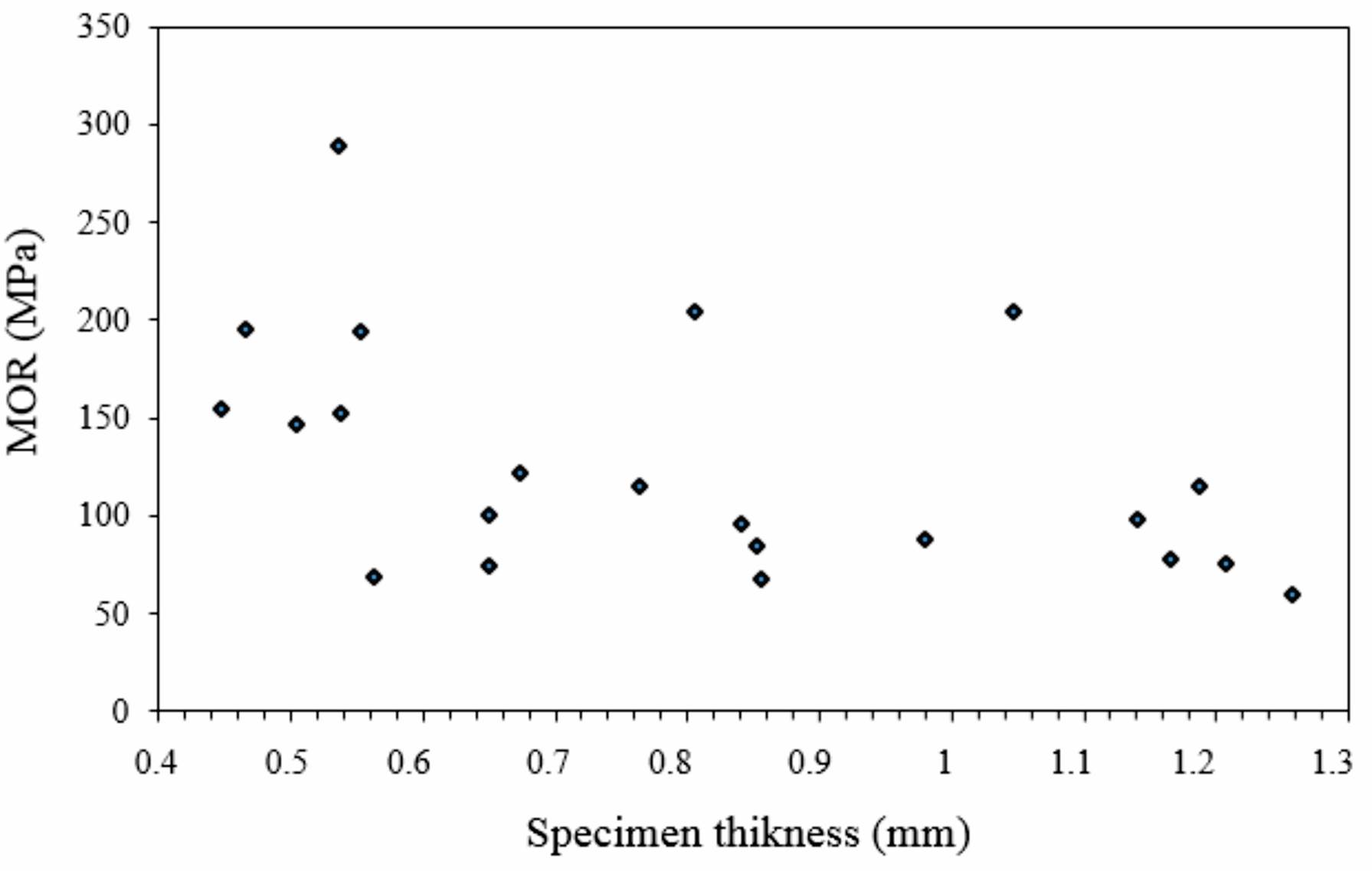

The behavior of MOR as a function of the shell thickness is shown in Figure 3, which shows that the flexural strength of the specimens extracted from P. dolioides shells does not have a clear dependence on the shell thickness.

The variation between averages of the results obtained from the bending tests performed on nine specimens drawn from three different shells, considering the positions T, A and B (as shown in Figure 1 c) are presented in Figure 4, the standard deviation in relation to the mean is presented as an error bar. It was possible to verify a strong influence on the mechanical properties as a function of the direction and position in which the specimens were removed from the shells.

Figure 4 MOR for nine specimens drawn from three different shells, showing the influence of the specimen removal position (T, A and B positions) on flexural strength.

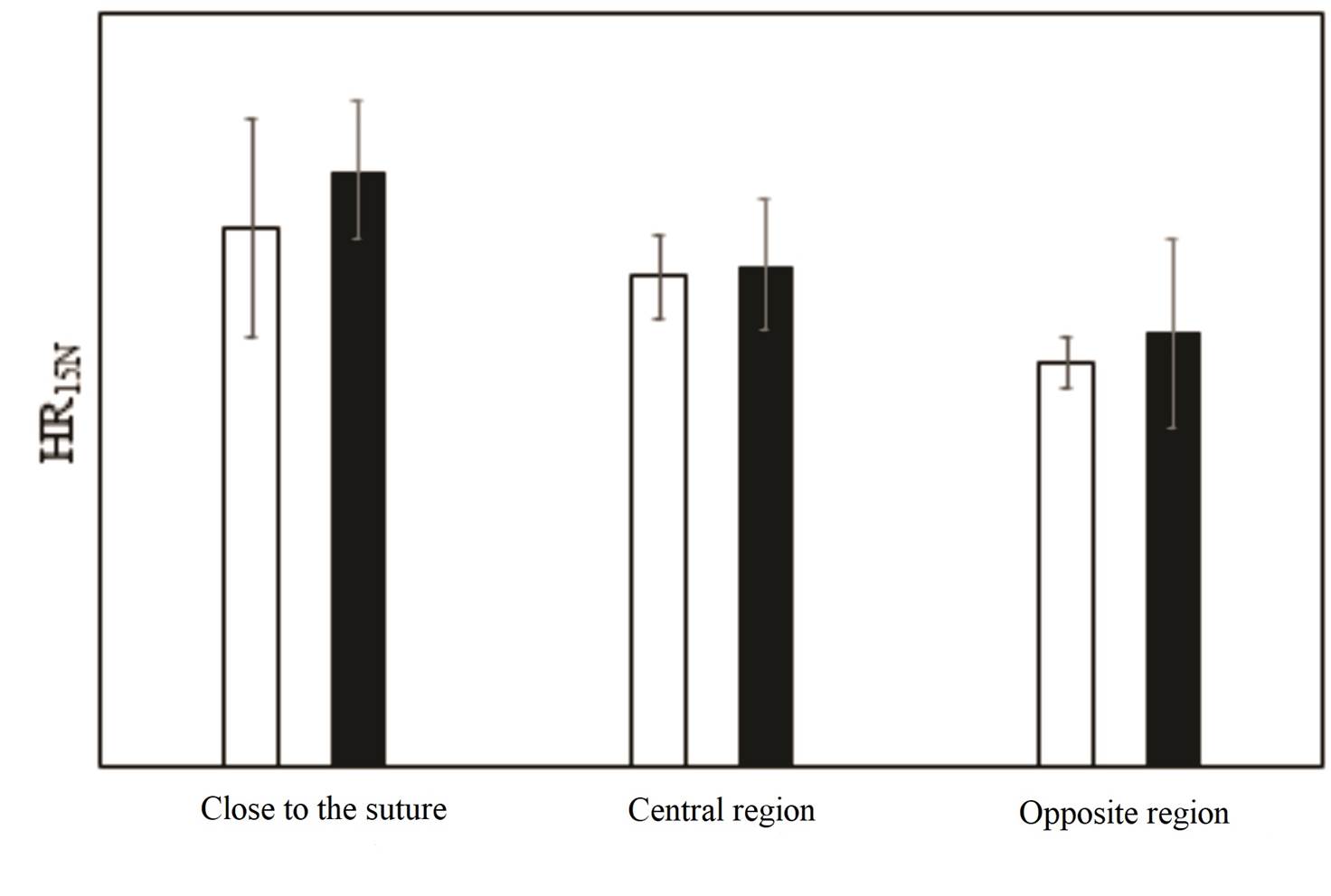

Rockwell surface hardness test. The tests were carried out only in the shell inner layer, since it was impossible to assess the shell outer layer, due to the difficulty to obtain specimens with suitable plans and sizes for the tests. All tests performed on outer layer shell resulted in specimen fracture. For the inner layer of shells with a thickness greater than 1.0 mm, of all samples analyzed, the mean hardness of HR15N = 50 and standard deviation 8.3 were obtained.

Figure 5 shows the Rockwell 15N surface hardness behavior of the analyzed shells for three different regions of the shell (close to the suture, center and opposite) and two shell sizes (82.45 mm and 78.05 mm), where the standard deviation from the mean is presented as an error bar, showing a tendency of the region close to the suture in presenting greater hardness HR15N.

Figure 5 Hardness HR15N of shells with average sizes of 82.45 mm (white) and 78.05 mm (black) in three different regions of the shell (close to the suture, central and opposite) for tests performed in triplicate.

Roughness Test. Roughness is a surface property of the material that characterizes surface irregularity. P. dolioides has great irregularity on its external surface, due to the characteristics of the growth rings added to the effect of environmental factors that can generate imperfections on the external surface, which can be clearly seen.

In relation to the shell inner layer, its surface shows a very low roughness index, as long as it has not undergone environmental damage after the death of the mollusk, as can be seen in Table 1, which shows roughness parameters such as the average roughness and the mean roughness amplitude, respectively 0.160 μm and 0.779 μm.

Table 1 Roughness parameters found in the test performed on the inner layer of a shell without signs of environmental wear: average roughness (Ra), square root of the arithmetic mean of squared deviations (Rq), average roughness of five points of the distances between the maximum peaks and deepest valleys (Rz), total roughness depth (Rt), maximum depth of the highest peak relative to the midline (Rp), maximum depth of the deepest valley over the midline (Rv) and maximum roughness (Ry).

| Roughness parameters | Measure (µm) |

|---|---|

| Ra | 0.160 |

| Rq | 0.182 |

| Rz | 0.779 |

| Rt | 0.779 |

| Rp | 0.300 |

| Rv | 0.479 |

| Ry | 0.779 |

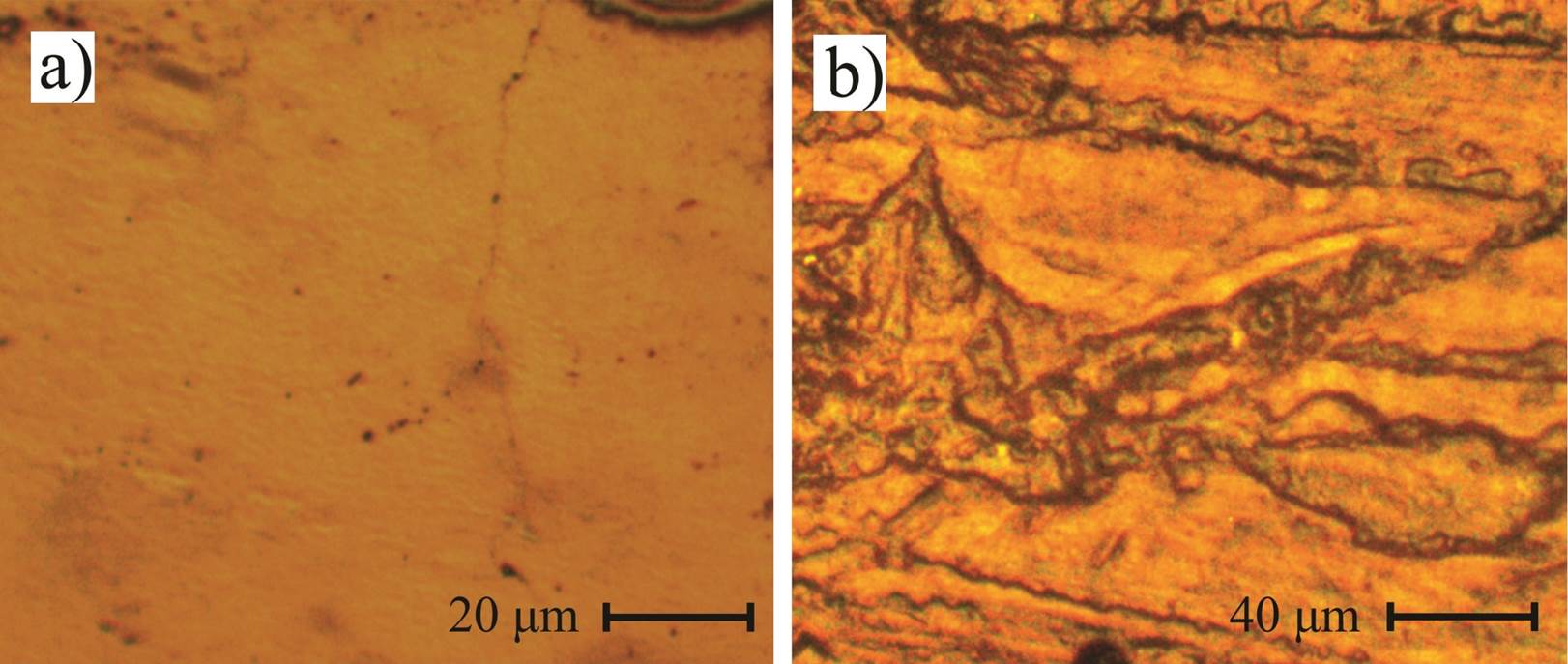

The roughness of the inner layer of P. dolioides is greatly affected by the action of the environment. Degraded shells show great roughness on the inner surface, as can be seen in the optical microscopy image of the inner layer of the shell Figure 6, with and without apparent signs of environmentally induced surface wear, Figure 6 a and b, respectively.

Discussion

The mechanical behavior analysis and discussion of P. dolioides shells is somewhat complex due to two main factors: the geometric shape and the heterogeneity of the natural shell material (Shojaei et al., 2012). The non-uniformity of the curvatures and the variations in the thickness of the shell make it difficult to remove standardized specimens. The heterogeneity of the shell forming composite due to differences in thickness and composition of the constituent layers of the shell generates anisotropy in the material (Liang et al., 2008). Added to these factors are the presence of defects, imperfections and even cracks in the shell, as well as genetic and environmental factors that may contribute to the variations in the mechanical resistance of the shell.

Bending test. The methodology used to obtain the flexural strength considering the curved shell geometry effect was successful, allowing to accomplish corrections in relation to ASTM C1161-13 standard, and permitting a new manner of flexural behavior analysis of P. dolioides specimens, as shown in Figure 2. The analysis of the curved geometry effect on the shell mechanical properties is very important because it directly affects the results of the mechanical tests as discussed in Neves & Mano (2005).

The mean value of MOR = 128.0 MPa, with values varying in range of 60 - 205 MPa, can be compared to the values presented for mollusks such as Conus striatus with flexural strength values ranging from 70-200 MPa (Curry & Kohn, 1976) and maximum flexual strength obtained for S. purpuratus shells (128 MPa), Tridacna gigas shells (87.1 MPa) and Tridacna maxima shells (117 MPa) (Liang et al., 2016). Currey & Taylor (1974) also found approximate values as 125 MPa for Conus Prometheus, 129.8 MPa for Hyriu ligutus and 123.6 MPa for Etisis siquillu.

Although large shells withstand higher loads, Figure 3 shows that MOR, the intrinsic property of the material, does not increase with thickness, instead, it presents a tendency of decrease the flexural strength with the increase of shell thickness.

Figure 4 shows a higher flexural strength (MOR) for specimens taken from positions A and B, where the specimens showed growth rings in the transverse direction with respect to their length, and lower MOR for position T, wherein the growth rings were in the direction along the length of the specimen. This result exposes the great anisotropy of the shell forming material, showing that the microstructural composite of CaCO3 constituent of the shell has great directional effect on the mechanical properties (Liang et al., 2008; Jiao et al., 2016).

The inner layer hardness of P. dolioides shells, HR15N = 50 ± 8.3, can even be compared to mollusks that have nacre in the inner layer, such as Pinctada maxima (Jameson 1901), Modiolus modiolus (Linnaeus, 1758) and Neotrigonia margaritacea (Lamarck, 1804), presenting a micro-hardness Vickers (HV) value near to 230 kgf / mm2 (≈ HR15N = 68) (Taylor and Layman, 1972). Values similar to natural calcite 2.27 GPa (231 kgf / mm2 ≈ HR15N = 68) (Lv et al., 2015). While Saxidomus purpuratus presented higher Vickers hardness values for the inner layer, 2.7 GPa (275 kgf / mm2 ≈ HR15N = 71) and central layer, 2.4 GPa (244 kgf / mm2 ≈ HR15N = 69) and lower for the outer layer 1.2 GPa (122 kgf / mm2 ≈ HR15N = 58) (Yang et al., 2011).

The dispersion of the internal layer HR15N values when analyzed in the same region of the shell can be attributed to shell heterogeneity and anisotropy, as well as to the influence of the irregularity of the outer layer (caused by the growth rings) and the shell curvature (Jiao et al., 2016). However, when the shell inner surface hardness is analyzed in relation to the regions of the mechanical tests, there is a tendency of the region close to the suture in presenting greater hardness HR15N, as shown in Figure 5.

The shell abrasion resistance characteristics, which contribute to the protection of the mollusk, are directly related to the shell surface hardness, therefore, it concludes that despite of its organic protective layer, the P. dolioides shell is very susceptible to the natural detrition from abrasive materials, such as sand or stones, due to its low surface hardness. This result shows the importance of the shell’s regeneration process and reconstitution for the mollusks protection.

Roughness. With the surface roughness test, it was possible to verify that the inner layer shell has a low average surface roughness, Ra = 0.160 μm (Table 1), comparable to a surface with fine grinding or fine polishing. This feature, the low roughness of the shell inner surface, can contribute to the sliding effect of the live animal inside the shell.

The surface roughness data of P. dolioides attained can be compared to the variation results of the surface roughness obtained using the technique of atomic force microscopy of growing edge of the mollusk (Graham & Sarikaya, 2000) estimated a rough value, Zrms = (0.71 ± 0.13) μm of the Haliotis rufescens inner layer shell, which can be compared to the maximum amplitude value, Rz = 0.779 μm, obtained using the rugosimeter.

The roughness test was performed on shell inner surface with no signs of environmental wear, as shown in Figure 6 (a), showing a fairly smooth surface, which is compatible with the roughness parameters found. However, for shells that have already undergone environmental action and showed signs of surface wear, valleys and depressions can be identified on the surface, as can be seen in Figure 6 (b).

Roughness analysis using the rugosimeter was a simple technique to obtain important information about the shell, since the internal surface roughness can be related to the size and distribution of the shell-forming crystalline CaCO3 microconstituents, which in turn can be related to the mechanical resistance of the shell (Graham & Sarikaya, 2000).

Conclusions

The methodology applied for the flexural test proved adequate for characterization of the mechanical flexural behavior of this type of material, in which the specimen resembles a curved beam, and it is possible to consider the curved geometry effect in the flexural strength calculations of the shell biocomposite.

The shells microstructural composite presents great anisotropy, with directional effect in the mechanical properties, in which the parallel direction to the growth rings presents less flexural strength. In this context, the superficial hardness results also show a tendency of the inner region close to the suture to present higher values of HR15N.

The results obtained in surface roughness test indicate that the shell inner layer has a low level of roughness, in addition, the roughness analysis using a rugosimeter represents a simple technique to obtain important information about the shell, since the surface roughness may be related to the size and distribution of the shell-forming CaCO3 crystalline microconstituents, which in turn may be related to the mechanical strength of the shell.

The mechanical behavior analyzed in this work can be used as a parameter for a better understanding of how the shell provides mollusk protection in relation to predator attack, animal defense mechanisms, abrasion and wear provided by the environment.

nueva página del texto (beta)

nueva página del texto (beta)