1 Introduction

Chalcopyrite compounds of the type I-III-VI2 (I: Cu, Ag; III: Al, Ga, In; VI: S, Se, Te) had been extensively studied due to their applications, particularly in thin-film solar cells [1-2]. However, in the last years, there was a renewed interest in these compounds, and their alloys, due to their possible utilization in thermoelectric conversion [3-7] and spintronic devices [8-10]. Moreover, a superconductor behavior observed in chalcopyrite alloys obtained by cationic substitution with transition metals (Nb and Co) has increased the attention on these versatile materials [11-12]. On the other hand, transition metal chalcogenides (TMC) based on Nb and Ta have caught the attention of the scientist for their topological crystal structure and unusual properties [13]. The latter includes charge density waves (CDW) [14] and superconductivity [15-18]. Naturally, part of the interest has focused on (I-III-VI2)/(TM-VI) alloys looking for room temperature ferromagnetism and high-temperature superconduction [11-12,19-22]. It is worth noting here that the origin of superconductivity in TMC (and in their alloys with chalcopyrites) is until now under investigation. From the crystallographic point of view, for TMC, the analysis differs for the bulk, which possesses a global inversion center, and a single monolayer which is non-centrosymmetric. The lack of a definite parity allows for the emergence of unconventional superconducting states. In (I-III-VI2)/(TM-VI) alloys there is a transition from the bulk form of I-III-VI2 to the layered form of TMC; how this transition takes place and when superconducting states appeared, are questions that must be investigated. A big help must be coming from ab initio calculations of the density of states (DOS) which might reveal the presence of flat bands and spikes in the DOS function characteristic of superconducting states.

CuInTe2 is a well-known semiconductor compound that crystallizes in the ordered chalcopyrite structure, space group

NbTe is a transition metal chalcogenide (TMC) that belongs to the Nb1-xTex system with x = 1/2; however, nominally NbTe generally exists as a mixture of NbTe2 (x = 2/3), NbTe3 (x = 3/4), and NbTe4 (x = 4/5) phases [25]. NbTe2 crystallizes in the monoclinic system (s.g. C2/m) with a layer-like structure [26] and can be considered as being made up of varying numbers of “layer molecules” within which the cations have either distorted octahedral or regular trigonal prismatic anion coordination [27]. It has been also reported that it is a superconductor metal with Tc ~ K [28]. NbTe3 is not stable in bulk, however, can be synthesized via nanoconfined growth within the stabilizing cavity of multiwalled carbon nanotubes [29]. NbTe4 crystallizes in a tetragonal structure (s.g

For the alloy CuNbInTe3 which corresponds to x = 1/2 in the (CuInTe2)1-x (NbTe)x system a much higher transition temperature Tc =12 K has been reported [12], indicative of the interest in the investigation of these new alloys. In this work, we report the synthesis and preliminary characterization of new components of the Cu-Nb-In-Te quaternary system (Fig. 1). In particular, the synthesis and structural characterization of the new alloy (CuIn)2NbTe5, belonging to the general (CuInTe2)1-x(NbTe)x system with x = 1/3, was performed.

2 Experimental details

(CuIn)2 NbTe5 was prepared by a solid-state reaction from a mixture of the elements Copper, Indium, Niobium, and Tellurium, with nominal purity of 99.99 wt. % (GoodFellow), and a nominal composition of Cu:In:Nb:Te = 2:2:1:5. The mixture was introduced into an evacuated (10-4 Torr) quartz ampoule, in which the inner walls were previously carbonized to prevent the chemical reaction of the elements with quartz. The quartz ampoule was sealed under vacuum and the fusion procedure was carried out inside a furnace heated up to 1500 K, at 20 K/h with a stop of 48 h at the melting point of Tellurium (723 K). The complete mixing of all the elements was assured using a shaking mechanical system during all the heating process, which was maintained for others 48 h. Then, the temperature was gradually reduced at the same rate of 20o/h, down to 900 K. The ampoule was kept at this temperature for 30 days. Finally, the sample was cooled to room temperature at a rate of 10o/h.

The chemical composition analysis of the sample was examined by scanning electron microscopy technique (SEM), using Hitachi S2500 equipment equipped with a Kevex accessory. The composition was found by an energy-dispersive x-ray spectrometer (EDS) coupled with a computer-based multichannel analyzer. For the EDS analysis, Kα lines were used. A standardless EDS analysis was made with a relative error of ± 5 - 10 % and detection limits of the order of 0.3 wt %, where the k-ratios are based on theoretical standards. Three different regions of the ingot were scanned, and the average atomic percentages were: Cu (20.4%), In (19.8%), Nb (9.7%), and Te (50.1%), which is in good qualitative agreement with the ideal composition 2:2:1:5.

Differential Thermal Analysis (DTA) measurements were obtained in the temperature range between 293 K and 1423 K, using a Perkin-Elmer DTA-7 with aluminum and gold used as reference materials. The charge of the powdered alloy was approximately 100 mg weight. Both heating and cooling runs were carried out on each sample, the average rates of these runs being approximately 10oC/min. The error in determining these temperatures is about ±10 K.

For the powder X-ray diffraction measurement, the synthesized sample was ground in an agate mortar and the resultant powder was dispersed on a zero-background Si sample holder. The X-ray powder diffraction data were collected at room temperature in a θ/θ reflection mode using a Siemens D5005 diffractometer. This instrument is equipped with an X-ray tube (CuKα1 radiation: λ= 54056 Å; 40 kV, 30 mA) and a diffracted beam graphite monochromator. A 1 mm aperture slit, a 1 mm divergence slit, a 0.1 mm monochromator slit, and a 0.6 mm detector slit were used. The specimen was scanned in the 2θ range of 10-100o with a step size of 0.02o and counting time of 50 s/step. Quartz was used as an external standard. The instrument analytical software was used to establish the positions of the peaks. For the Rietveld refinement, the whole diffraction data was used.

3 Results and discussion

3.1 Differential thermal analysis

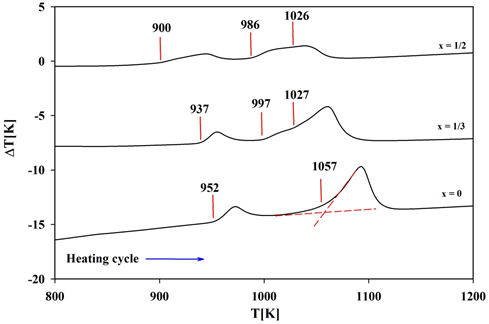

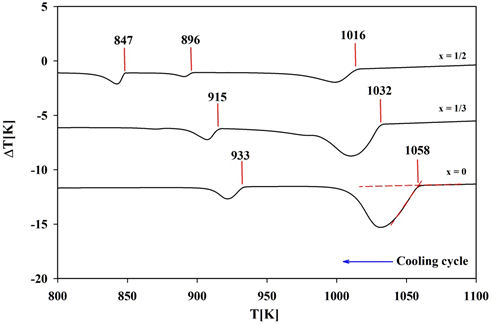

The DTA heating and cooling curves, for compositions x = 0, 1/3 and 1/2, belonging to the (CuInTe2)1-x(NbTe)x alloy system is displaying, for comparison, in Fig. 2 and 3, respectively. The values obtained for CuInTe2 (x = 0) are in good agreement with those reported previously [30,31]. It can be observed in the heating curves that the congruent melting of CuInTe2 decreases in temperature with the composition value x and becomes incongruently. This behavior is indicative that compositions and x = 1/3 and x = 1/2 are alloys and not intermediate compounds in the phase diagram. (CuIn)2NbTe5 melts incongruent at 1026 K.

Figure 2 DTA heating cycle for the (CuInTe2)1-x(NbTe)x alloy system. The dashed red line indicates the accepted criteria (intercept of the baseline with the slope of the peak) for the determination of the thermal transition values (continuous red line and numbers).

Figure 3 DTA cooling cycle for the (CuInTe2)1-x(NbTe)x alloy system. The dashed red line indicates the accepted criteria (intercept of the baseline with the slope of the peak) for the determination of the thermal transition values (continuous red line and numbers).

In the cooling cycle is observed the apparition of a new peak at 847 K; this solid-to-solid transition may be associated with cationic disordering, but with the available experimental data the complete determination can be only speculative.

3.2 Crystal structure analysis

The powder X-ray diffraction pattern of (CuIn)2NbTe5 was indexed using

the Dicvol program [32] in the Winplotr suite [33]. A tetragonal

cell of dimensions a = 5.780(1) Å, c =

11.610(2) Å was obtained. These parameters are similar in magnitude to the

parent’s chalcopyrite structure CuInTe2[23]. The systematic

absence condition in the general reflections of the type hkl

indicates a P-type cell, and the hhl:l = 2n

and 00l : l = 2n conditions suggests the space

groups

The Rietveld refinement analysis was performed using the Fullprof program [35]. The refinement parameters were scale factor, background, unit cell parameters, peak profile, and atomic coordinates. With the powder laboratory diffraction data available it was only possible to describe the thermal motion by one isotropic temperature factor for each type of atom. The angular dependence was described using the Cagliotti formula [36], and the peak shapes were described by the Thompson-Cox-Hastings pseudo-Voigt profile function [37]. Details of the crystal data collection and structure refinement are summarized in Table I. Table II show the crystallographic information obtained from the final adjustment. The Rietveld refinement plot is displayed in Fig 3.

Table I Experimental details and Rietveld refinement results for Cu2NbIn2Te5.

| Data collection | |||

| Diffractometer | Siemens D5005 | Temperature (K) | 298(1) |

| Mode | Reflection | wavelength (CuKα) | 1.54056 Å |

| Scan method | Step | step size 2θ(o) | 0.02 |

| data range 2𝜃(o) | 10-100 | counting time (s) | 40 |

| Crystal Data | |||

| Chemical Formula | (CuIn)2NbTe5 | Formula Weight (g/mol) | 807.38 |

| Crystal system | Tetragonal | Space group |

|

| dcalc(g/cm-3) | 7.45 | Z | 1.6 (8/5) |

| a (Å) | 6.1964(2) | c/a | 2.01 |

| c (Å) | 12.4761(4) | V (Å3) | 479.02(3) |

| Refinement | |||

| step intensities | 4501 | independent reflections | 152 |

| Rexp (%) | 7.0 | Rwp (%) | 8.1 |

| Rp (%) | 7.7 | RB (%) | 7.5 |

| S | 1.2 | ||

Table II Atomic coordinates, Wyckoff position, occupancy factors, isotropic temperature factors, bond, and angle distances for (CuIn)2 NbTe5, derived from the Rietveld refinement, and Bond Valence Sum (BVS) calculations.

| Atom | Ox. | BVS | Wyck. | x | y | z | foc | B(Å2) |

|---|---|---|---|---|---|---|---|---|

| Cu1 | +1 | 1.4 | 2e | 0 | 0 | 0 | 1 | 0.6(1) |

| Nb | +2 | 2.3 | 2d | 0 | 1/2 | 1/4 | 0.8 | 0.5(1) |

| Cu2 | +1 | 2d | 0 | 1/2 | 1/4 | 0.1 | 0.6(1) | |

| In2 | +3 | 2d | 0 | 1/2 | 1/4 | 0.1 | 0.9(1) | |

| In1 | +3 | 3.1 | 2b | 1/2 | 0 | 1/4 | 1 | 0.9(1) |

| Cu3 | +1 | 2f | 1/2 | 1/2 | 0 | 0.5 | 0.6(1) | |

| In3 | +3 | 2f | 1/2 | 1/2 | 0 | 0.5 | 0.9(1) | |

| Te | -2 | 2.2 | 8n | 0.2516(7) | 0.2558(7) | 0.1187(5) | 1 | 1.2(1) |

| Cu1-Te | 2.671(2) | In1-Tei | 2.750(2) | Nb-Te | 2.721(2) | |||

| Teiiu1-Te | 107.90(5) | Teiiu1-Teiii | 112.66(4) | Teviii-Cu2-Te | 108.67(5) | |||

| Tevin1-Tei | 109.62(5) | Tevin1-Tevii | 106.89(4) | Tevin1-Te | 111.94(5) | |||

| Te-Nb-Teiv | 110.09(5) | Te-Nb-Tev | 105.97(4) | Teviii-Cu2-Teix | 111.09(4) | |||

Symmetry codes: (i) 1-x, -y, z; (ii) -y, x, -z; (iii) y, -x, -z; (iv) x, 1-y, 0.5-z; (v) -x, 1-y, z; (vi) x, -y, 0.5-z; (vii) 1-x, y, 0.5-z; (viii) y, 1-x, -z; (ix) 1-y, x, -z.

The crystal structure of (CuIn)2NbTe5 is shown in Fig. 4. This corresponds to a normal adamantane structure [38] with a P-chalcopyrite structure [39], which consists of a three-dimensional arrangement of distorted CuTe4, InTe4, and NbTe4 tetrahedral. This array is expected for adamantane compounds [38] and is characterized by the tetrahedral coordination of both cations and anions. Figure 5 shows a projection of the tetrahedral packing of (CuIn)2 NbTe5 along the ca plane. It is possible to observe that the structure is characterized by a double alternation of tellurium-cations layers along the 010 direction according to the sequence: Te-Te : Nb-In-Nb-In : Cu-In-Cu-In : Te-Te.

To check the refined crystal structure model, empirical Bond Valence Sum (BVS) was calculated. This method allows to analyze interatomic distances using the BVS formula

Interatomic distances are shorter than the sum of the ionic radii for

4 Conclusions

The quaternary alloy (CuIn)2NbTe5 was prepared by the melting and annealing method and its crystal structure refined using powder X-ray diffraction data. This compound is isotypic with Cu2FeIn2Se5 and crystallizes through a P-chalcopyrite fashion in a normal adamantane structure with tetrahedral coordination around cations and anions. The structure is characterized by a double alternation of anion-cation layers. The chemical structure was checked by analysis of the interatomic distances using the Bond Valence Sum (BVS) formula based on bond-strength examination. The new quaternary alloy melts incongruent at 1026 K.

nueva página del texto (beta)

nueva página del texto (beta)