1. Introduction

The addition of a II-VI binary to chalcopyrite I-III-VI

These types of materials have received considerable attention mainly because they can

be useful for their potential applications in the fabrication of low cost solar

cells and their large magneto-optical effects, which are observed when II are

paramagnetic atoms [10,11]. We are currently investigating the synthesis and

structural characterization of chalcogenide diamond-like families [12-16],

and as part of ongoing studies, in this work we report the synthesis and a

crystallographic characterization of the new chalcogenide quaternary compound CuVInSe

2. Experimental

2.1. Preparation of the sample

Polycrystalline sample was synthesized using the melt and annealing technique.

Stoichiometric quantities of the elements with purity of 99.99% were charged in

a synthetic silica glass ampoule, which was previously subjected to pyrolysis in

order to avoid reaction of the starting materials with silica glass. Then, the

ampoule was sealed under vacuum (

2.2. Scanning electron microscopy

The stoichiometric relation of the samples was investigated by Scanning Electron

Microscopy (SEM) technique, using a FE-8 SEM, Jeol 6301-F equipment. The

micro-chemical composition was found using an energy dispersive X-ray

spectrometer (EDS) coupled with a computer-based multichannel analyzer (MCA),

(Delta III analysis and Quantex software, Kevex). For the EDS analysis K

2.3. Differential thermal analysis

The differential thermal analysis (DTA) was carried out in a fully automatic

Perkin-Elmer apparatus with Pt/Pt-Rh thermocouples. Au or Ag was used as

internal standards, according to the expected melting point of the sample. The

heating and cooling rates were controlled to 20 K/h. Transition temperatures

were manually obtained from the

2.4. X-ray powder diffraction

A small amount of the sample was ground in an agate mortar and pestle and mounted

on a flat zero-background holder covered with a thin layer of petroleum jelly. A

Siemens D5005 powder diffractometer was used for data collection with the

conditions given in Table I. The X-ray

Power Difraction (XRPD) data was collected at 293(1) K, in

TABLE I Experimental parameters for data collection of the CuVInSe3 compound.

| diffractometer | Siemens D5005 | 2θ range | 10-100° |

| radiation | CuKα | step size | 0.02° (2θ) |

| instrumental settings | 40 kV, 30 mA | counting time | 40 s |

| wavelenght | λ = 1:54056 Å | specimen rotation | 15 r.p.m. |

| monocrhomator | graphite | external standard | quartz |

| scan mode | θ/2θ (reflection) | temperature | 298(1) K |

3. Results and Discussion

3.1. Scanning Electron Microscopy

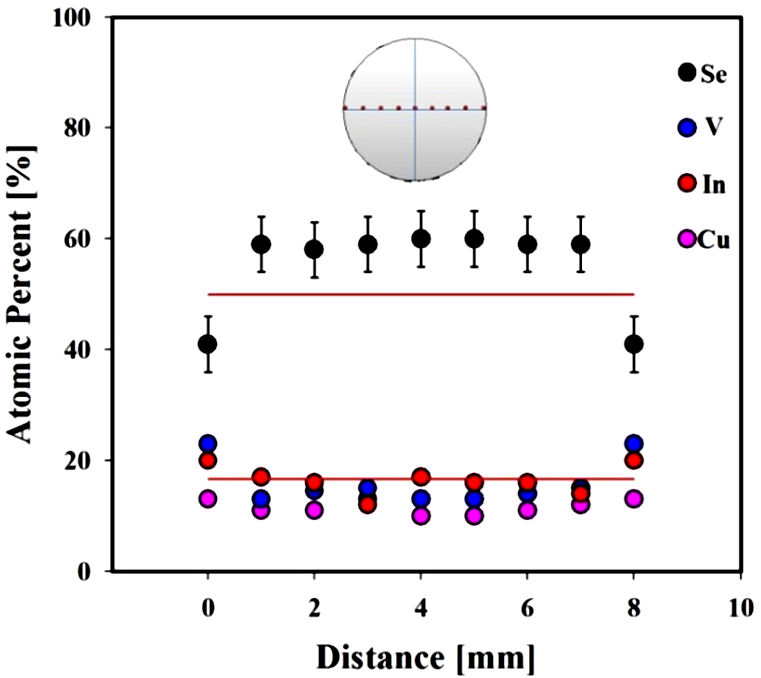

The obtained ingot (15 mms long and 8 mms diameter) was homogeneous at sight, with no voids in the surface and light gray color. As it is routine in our laboratory, stoichiometry and homogeneity of the ingots are tested using scanning electron microscopy (SEM); for that, a slice 1 mm thick was cut from the center of the ingot. In Fig. 1, the results of SEM measurements are shown. It When measured, a little excess of selenium was found in the points located in the inner part of the slice whereas for the nearest points to the external surface of the ingot the selenium is in defect. This behavior may be due to the long period of annealing (30 days) for which little amounts of selenium in the surface of the ingot may go out. For Se, the measured values are ∼3% higher that the estimated experimental error (±5%); for cations Cu, In and V, the measured values are in agreement with nominal in the range of the experimental error.

Figure 1 SEM measurements for CuVInSe

3.2. Differential thermal analysis (DTA)

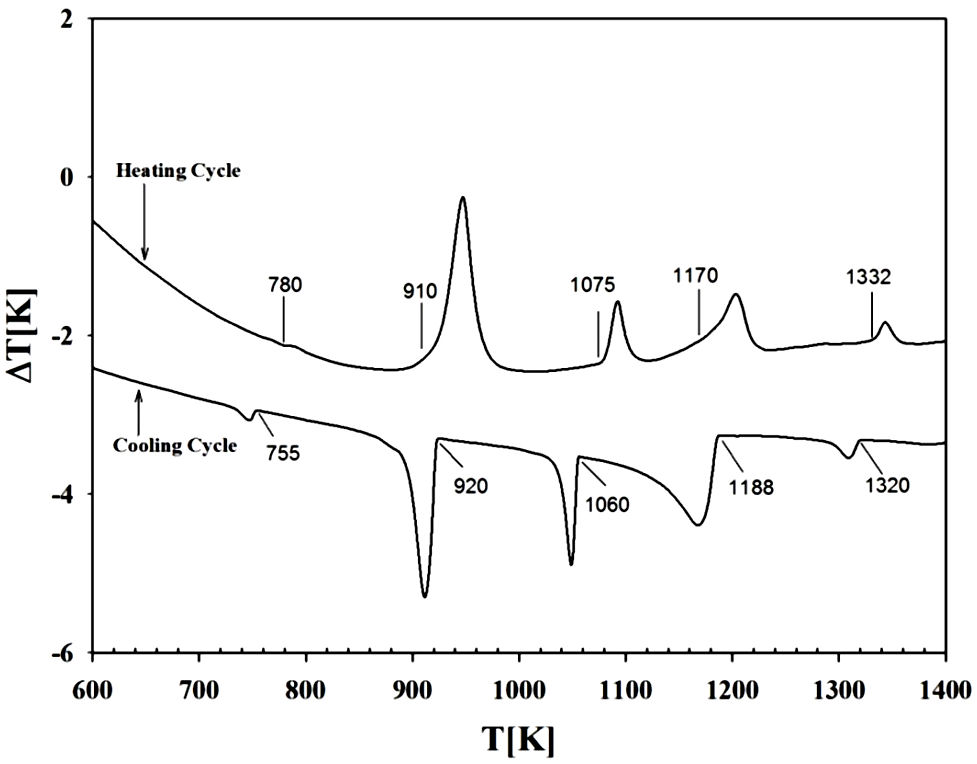

DTA runs were carried out on the sample as indicated above. The transition

temperatures as well as the type of melting were obtained from the peaks on the

DTA heating and cooling curves. Each transition temperature was determined from

the base intercept of the tangent to the leading edge of the peak in the

differential signal (see Fig. 2). It can be

observed that CuVInSe

3.3. X-ray powder diffraction analysis

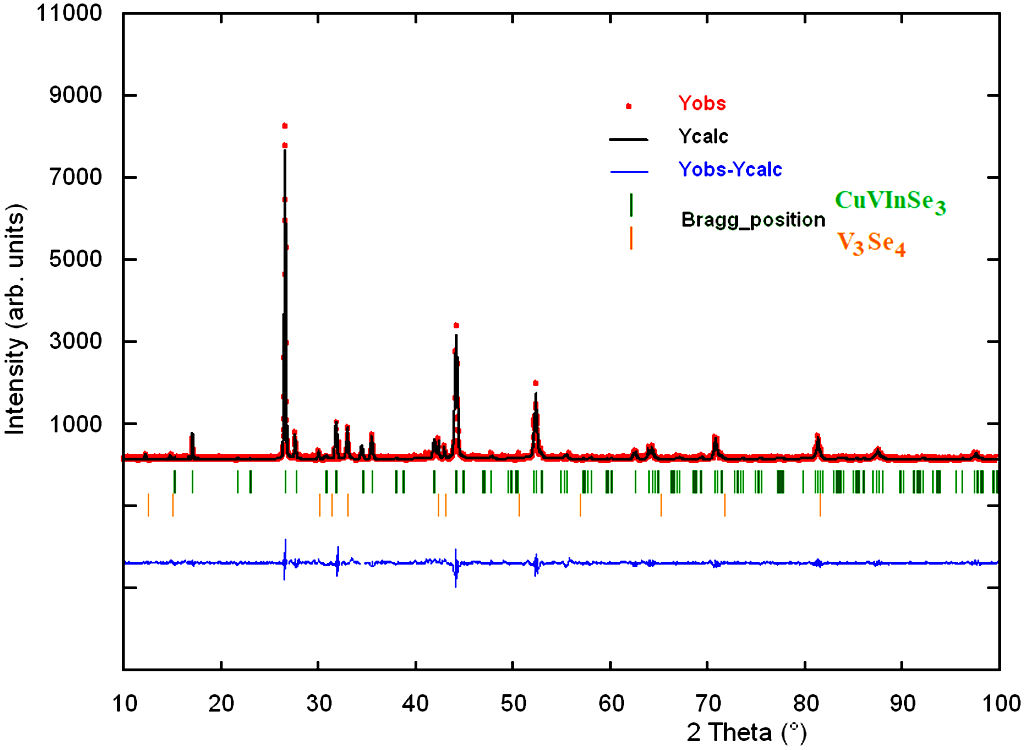

The X-ray powder pattern of CuVInSe

Figure 3 Final Rietveld plot showing the observed calculated and

difference pattern for the CuVInSe

The Rietveld [19] refinement was performed

using the Fullprof program [20]. The

indexed unit cell results were taken as starting parameters. Atomic positions of V

TABLE II Results of Rietveld refinement for CuVInSe3

| Molecular formula | CuVInSe |

D |

5.29 (g/cm |

| Molecular weight | 1243.0 (g/mol) | N |

4001 |

| Crystal system | Orthorhombic | N |

153 |

| Space group | P |

Peak-shape profile | Pseudo-Voigt |

| Z | 2.667 (8/3) | Rexp | 6.6 % |

| a | 5.7909(4) | Rp | 8.7 % |

| c | 11.625(1) | Rwp | 8.8 % |

| V | 389.84(5) | S | 1.3 |

Figure 3 shows the observed, calculated and difference profile for the final cycle of Rietveld refinement. The lower trace is the difference curve between observed and calculated patterns. The Bragg reflections are indicated by vertical bars. Unit cell parameters, atomic coordinates and isotropic temperature factor are shown in Table III.

TABLE III Unit cell, atomic coordinates, isotropic temperature factors for CuVInSe3, derived from the Rietveld refinement M = (Cu1+V1+In1)

| Space group P | |||||||

| Atom | Ox. | Site | x | y | z | foc | B (Å2) |

| Cu | +1 | 2e | 0 | 0 | 0 | 1 | 0.4(4) |

| V | +2 | 2d | 0 | 1/2 | 1/4 | 1 | 0.4(4) |

| In | +3 | 2b | 1/2 | 0 | 1/4 | 1 | 0.4(4) |

| 2f | 1/2 | 1/2 | 0 | 1/3 | 0.4(4) | ||

| M | 2f | 1/2 | 1/2 | 0 | 1/3 | 0.4(4) | |

| 2f | 1/2 | 1/2 | 0 | 1/3 | 0.4(4) | ||

| Se | -2 | 8n | 0.2553(5) | 0.2572(5) | 0.1231(3) | 1 | 0.4(4) |

Table IV shows the distance lengths and

bond angles for CuVInSe

TABLE IV Distance lengths (Å) and bond angles (°) for CuVInSe3.

| Cu-Se | 2.518(3) | V-Se | 2.540(3) | In-Se | 2.530(3) | M-Se | 2.456(3) |

| Seiii-Cu-Seiv | 108.1(1) | Seiii-Cu-Sev | 112.1(1) | Seiii-Cu-Se | 108.3(1) | ||

| Seiv-Cu-Sev | 108.3(1) | Seiv-Cu-Se | 112.1(1) | Sev-Cu-Se | 108.1(1) | ||

| Se-V-Sexii | 108.5(1) | Sex-V-Sexi | 108.5(1) | Sex-V-Se | 108.5(1) | ||

| Sex-V-Sexii | 111.4(1) | Sexi-V-Se | 111.4(1) | Sexi-V-Sexii | 108.5(1) | ||

| Se-In-Sei | 107.9(1) | Se-In-Seviii | 111.9(1) | Se-In-Seix | 108.7(1) | ||

| Seviii-In-Sei | 108.7(1) | Seviii-In-Seix | 107.9(1) | Sei-In-Seix | 111.9(1) | ||

An important structural characteristic is the parameter of tetragonal lattice

distortion, which is determined as a deviation of the ratio

CuVInSe

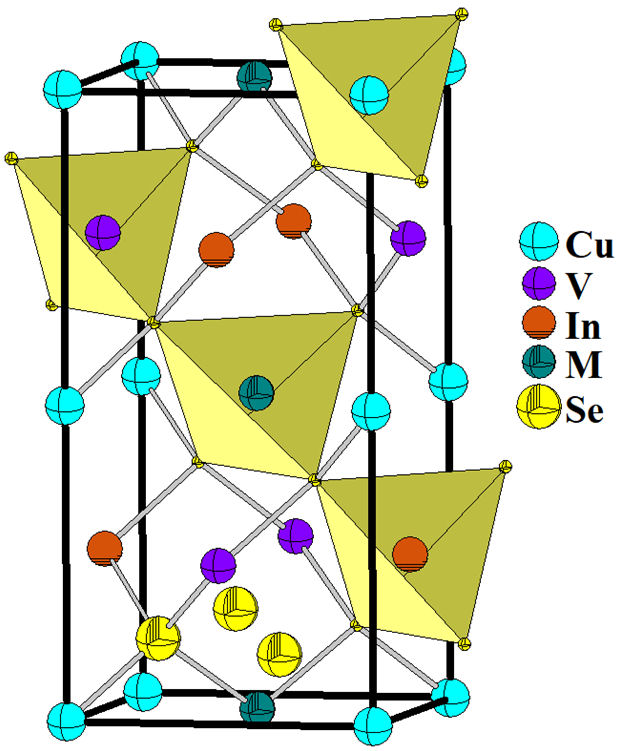

Figure 4 Unit cell diagram for the quaternary chalcogenide CuVInSe

The interatomic distances are shorter than the sum of the respective ionic radii

for structures tetrahedrally bonded[26].

The bond distances Cu-Se [2.518(3) Å], V-Se [2.540(3) Å] and In-Se [2.530(3) Å]

agree well with those observed in other adamantane compounds such as CuInSe

4. Conclusions

A new quaternary chalcogenide has been synthetized and structurally characterized.

The DTA indicates that this compound melts at 1332 K. The crystals of

CuVInSe3 belong to the tetragonal system with space group P

nova página do texto(beta)

nova página do texto(beta)