1. INTRODUTION

Commonly, aggregates in concrete are two-thirds of the total volume and can influence in high grades the workability, mechanical properties, durability and porosity. In addition, they had used to reduce costs and provide stability. Therefore, aggregates characterization is essential to design and predict concrete behavior.

Concrete from Yucatán Península is made with crushed limestone aggregates with higher absorption, porosity, fineness powders, fragility and lower density. These properties are proper of deficient aggregates compared with lower absorption aggregates (Moreno and Arjona, 2011). Hence, the aggregate phase has influence in the mechanical properties of the concrete as Compressive Strength (CS) and Elastic Modulus (EM) and trigger an increase the cement amount to achieve target mechanical properties. Given these conditions, Solís and Moreno (2012) investigated the maximum CS in concretes with High Absorptions Crushed Limestone Agreggates (HACLA) and a w/c ratio between 0.20 and 0.45. The volume of cement was from 460 to 1300 kg/m3 without pozzolans. The maximum CS was around 500 kg/cm2 at 28 days and 600 kg/cm2 at later ages. There was not a significant increase in CS with higher volumes of cement such as 850 kg/m3 because the aggregates strength was exceeded. Cement is the most expensive material both economically and environmentally in concrete, therefore supplementary cementitious materials could be considered as a requierement in any construction. Pozzolans are siliceous or siliceous and aluminous material, which in itself possesses little or no cementitious value but will, in finely divided form and in the presence of moisture, chemically react with calcium hydroxide at ordinary temperatures to form compounds possessing cementitious properties (ASTM C 125). Therefore, pozzolans are used to Portland Cement substitutions or as mineral admixtures to achieve similar or higher mechanical properties in Portland Cement based concretes.

Pozzolans are not commonly used in Yucatan Peninsula due to the lack of volcanic activity near from the región and industry development without puzzolanic residues. However, Aportela and Pardo L. (2002) studied the technical feasibility to use natural fly ash from Popocatepetl volcano as a supplementary cementitious materials in concrete with HACLA, authors observed a decrease in Compressive Strenght when this fly ash was added to concrete.

At Nava, México region, a significant amount of Fly Ash (FA) is obtained from a carboelectric factory due to pulverized carbon burn. This FA is classified as an artificial type F due to the origin and oxide composition according to ASTM C 618. It has been reported concrete with high compressive strength due to high contents of FA from Nava region and with low content of Portland Cement (100-150 kg/m3), and the use of superplasticizer is a key to achieve the flowability (Valdez P. et al. 2007). Pozzolanic Activity was not investigated in Valdez P. work; However, if compressive strength increases, elastic modulus should increase too, therefore, FA from Nava was consider as a material with potential in concrete industry at México.

Siddique R. (2003) investigated mechanical properties of concrete (CS and EM) with fly ash mineral additions in 10%, 20%, 30%, 40% y 50%; higher values were obtained from the mixtures with mineral additions compared to the reference, also it was conclude that FA class F can be use for structural porpuses.

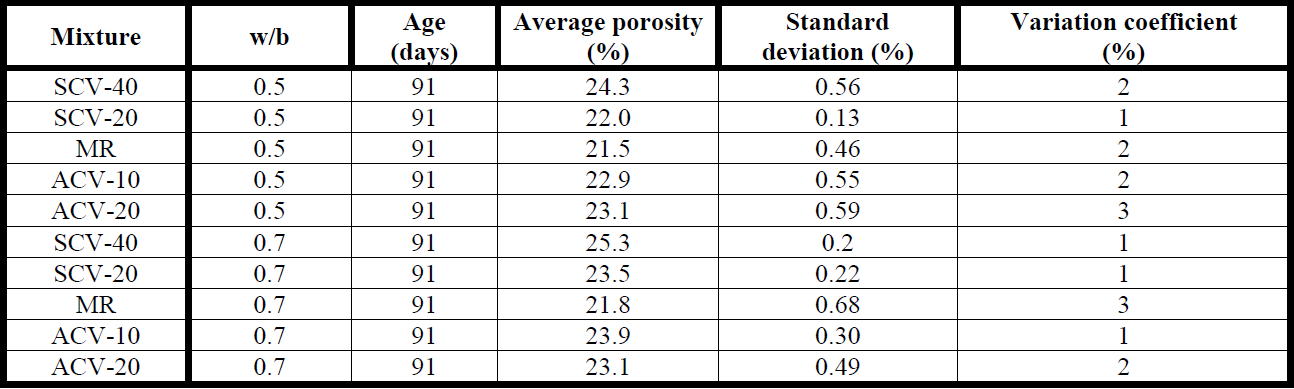

Porositys registered in concrete with HACLA oscilate between 18% and 25% for different water/cement ratios, this value is higher than concretes made with another kind of aggregates. A decrease of the porosity in cement paste phase with FA from Nava region is propose as a solution to enhance mechanical properties on concrete with HACLA.

The main objective from this work is to determine the performance of FA to decrease porosity and enhance mechanical properties such as Compressive Strenght and Elastic Modulus in concrete with HACLA. Another focus is to optimize the amount of cement paste when is partially substituided by FA. However, from social perspective, the use of an industrial waste as fly ash also has an important impact in the region where is produced.

2. EXPERIMENTAL PROCEDURE

Materials used to cast concrete mixtures were characterize according to American Society of Testing Materials (ASTM) standards. Composite Portland Cement (CPC 30R) was used in the cast of specimens due to his often use at Yucatán Península and the materials for this project has to be the closest possible to the construction field. This cement satisfy the requirements from NMX C-414 ONNCCE norm.

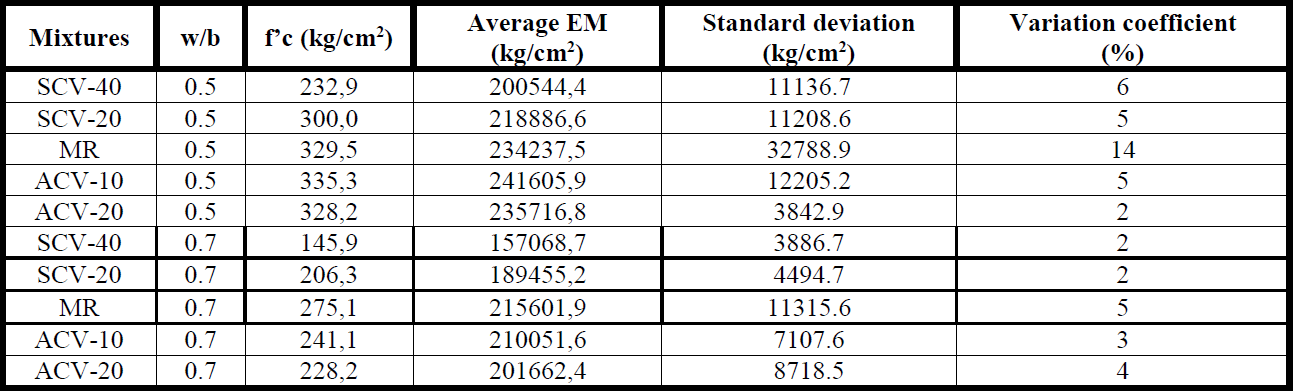

Morphology from FA was performe with an Image Analysis through Scanning Electronic Microscope (SEM), oxide composition was calculate by X-ray fluorescence (FRX), Particle Size Distribution was performe by Laser diffraction; also, Pozzolanic Activity Index (PAI) and Density were measured.

Mixture proportions were calculate according to American Concrete Institute Code (ACI 211.1) with two modifications:

Absorption of coarse and fine aggregates was consider as the 70% of the calculated absorption according to ASTM C127/C128 standards because of saturation on aggregate samples were during 15 and 60 minutes instead of 24 houres after being dried in the furnace at 100°C for 24 hours (Hernández, 2013)

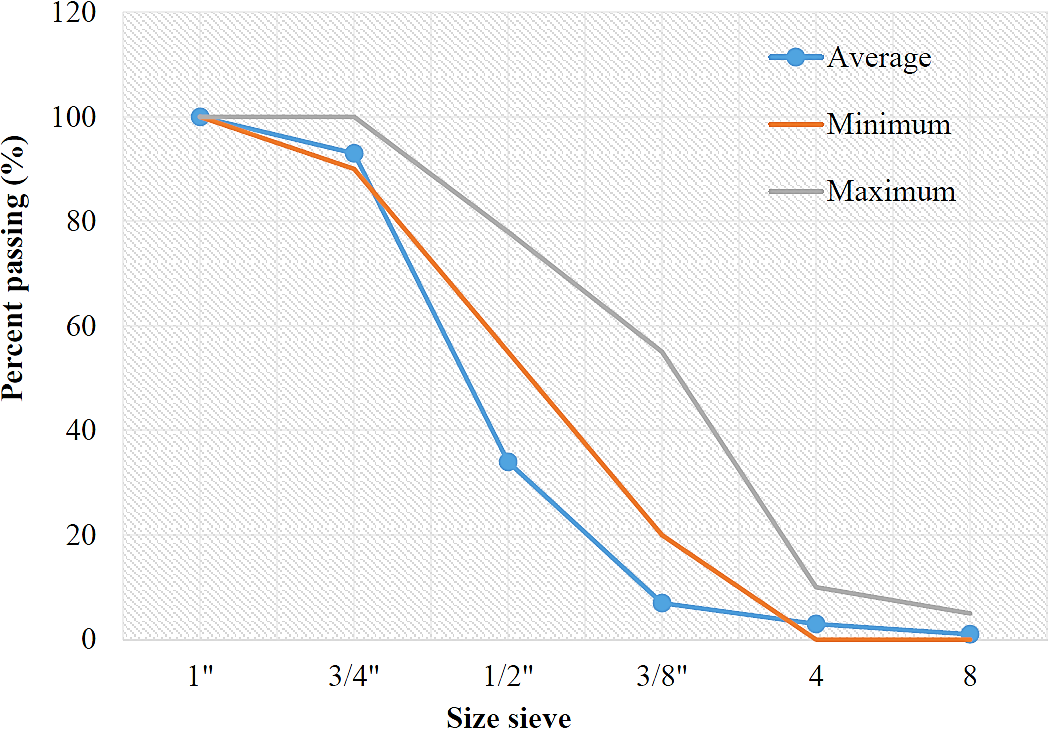

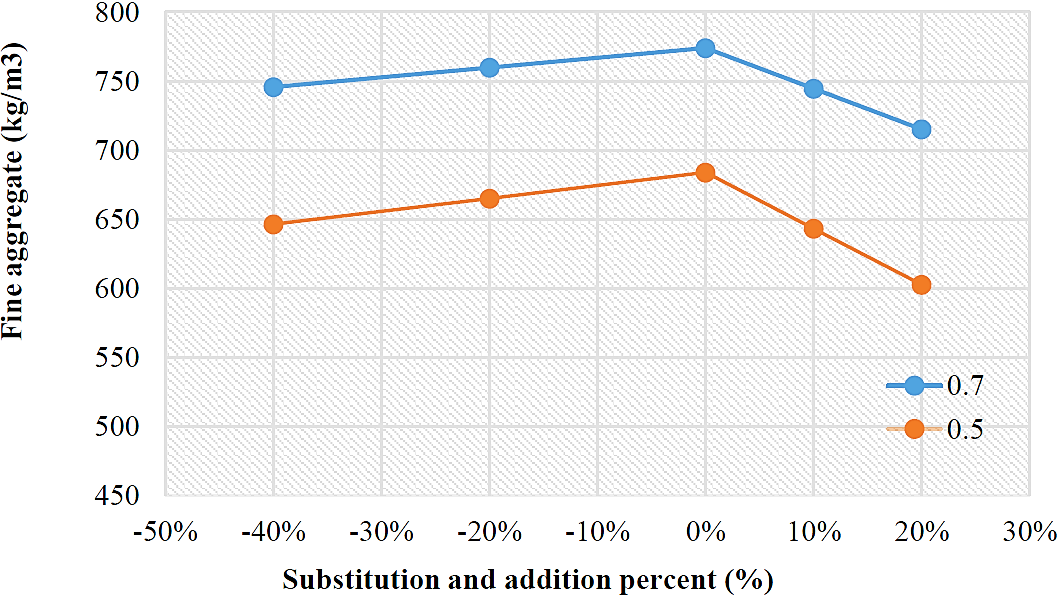

Fly ash addition as a supplementary cementitious material (Mixtures SCV-20 and SCV-40, Table 1) and as mineral admixture (Mixtures ACV-10 and ACV-20). When fly ash was added, fine aggregate was replace in mixtures.

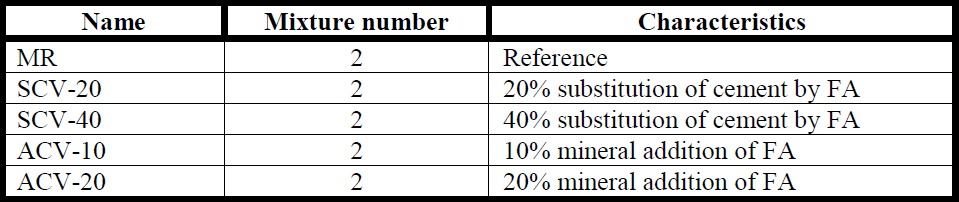

Ten mixtures were design with water/binder (w/b) ratio of 0.5 and 0.7. At Table 1, nomenclature of mixtures is given to practical reading porpuses. Each mixture was of 55 liters and the numbers of especimens are presented at Table 2. The specimens were cast according to ASTM C 31 and were cure with limewater.

Compressive Strenght, Elastic Modulus and porosity measurements were determine according to ASTM standards.

3. RESULTS

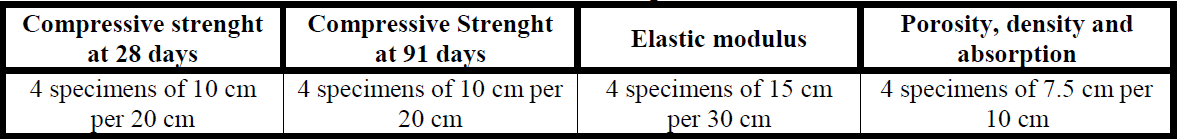

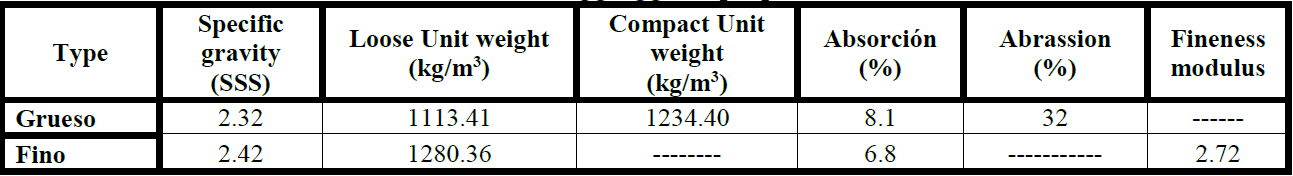

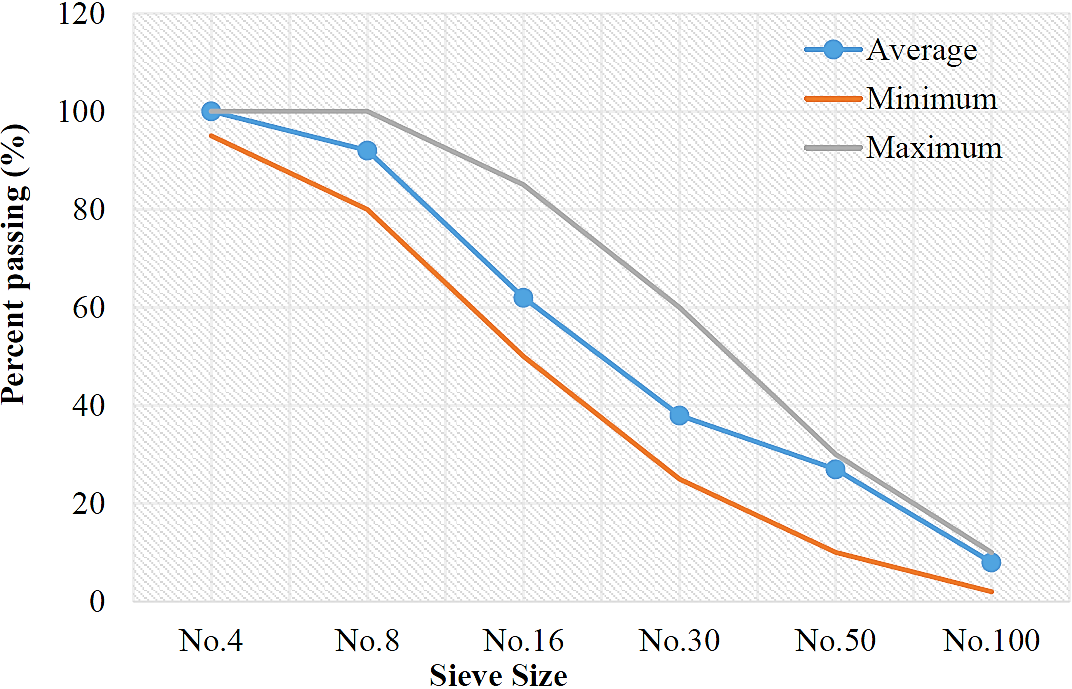

Physical characterization of fine and coarse aggregates such as unit weight, specific gravity, absorption, abrasive resistance and fineness modulus are given at Table 3. Presented values are the average of 3 samples. Particle size distribution of fine and coarse aggregates are presented at Figures 1 and 2. It´s observed that coarse aggregates do not satisfy ASTM C33 especifications in contradistinction to fine aggregates.

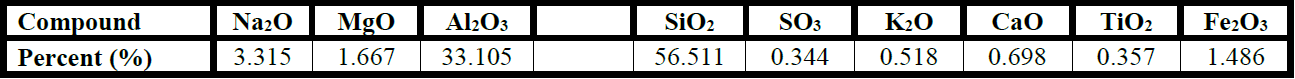

Fly ash should satisfy certain oxide composition, fineness and a Pozzolanic Activy Index to use within concrete according to ASTM C618. Total Oxide amount of aluminium, silica and iron should be as minimum 70% (Table 4). Density of fly ash was 2.0 g/cm3 according to ASTM C 311 and C188 method.

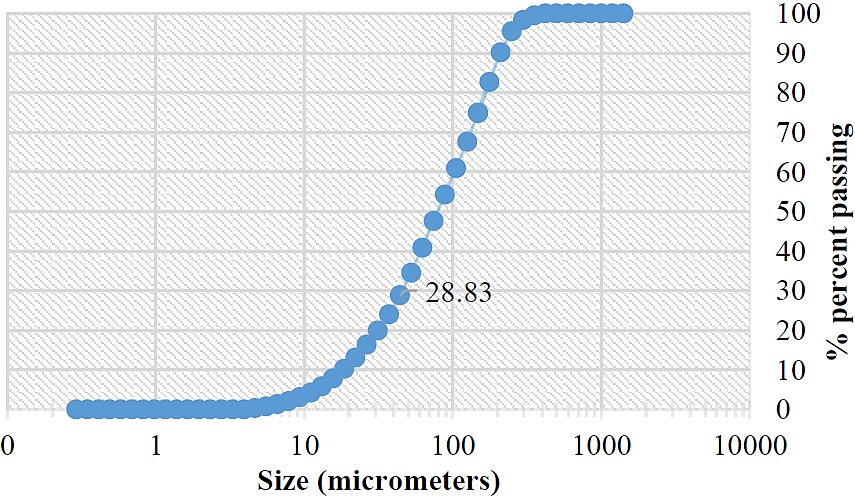

Particle size distributtion of fly ash was determine through difrattion laser with a MICROTRAC equipment (Figure 3). According to ASTM C 618, fly ash shouldn´t retain more than 35% of his total weight through sive no. 325 of 45 micrometers.

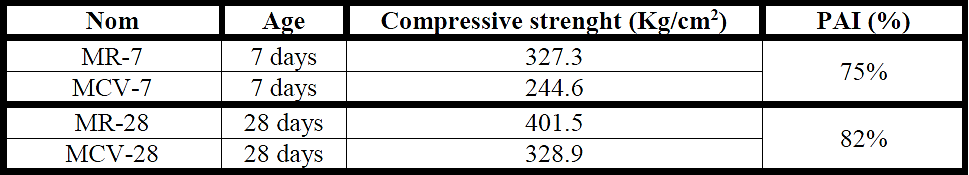

Finally, according to ASTM C 618, fly ash should obtain a PAI mínimum of 75% at 7 or 28 days to be considered as a pozzolan in concrete. Results are given at Table 5.

Scanning Electronic Microscope images were taken at 1000 and 10000 x (Figure 4).

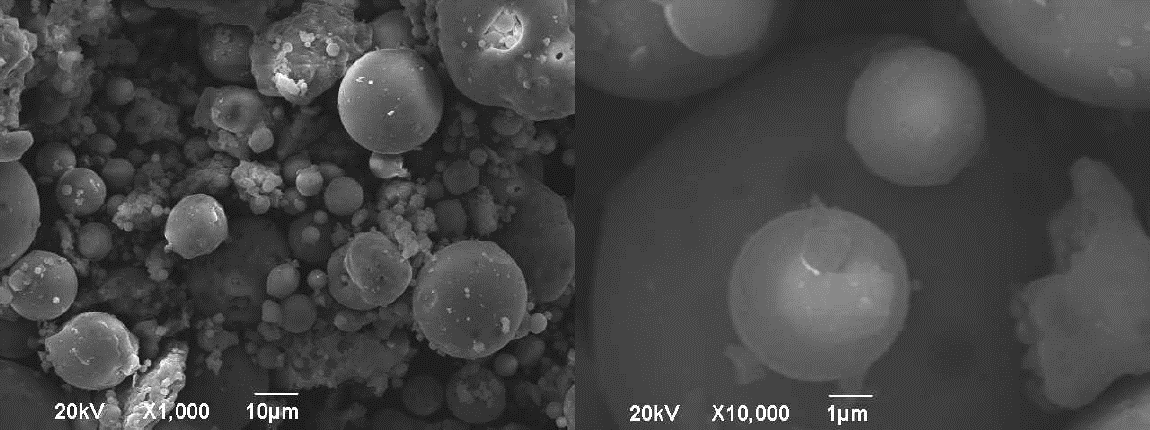

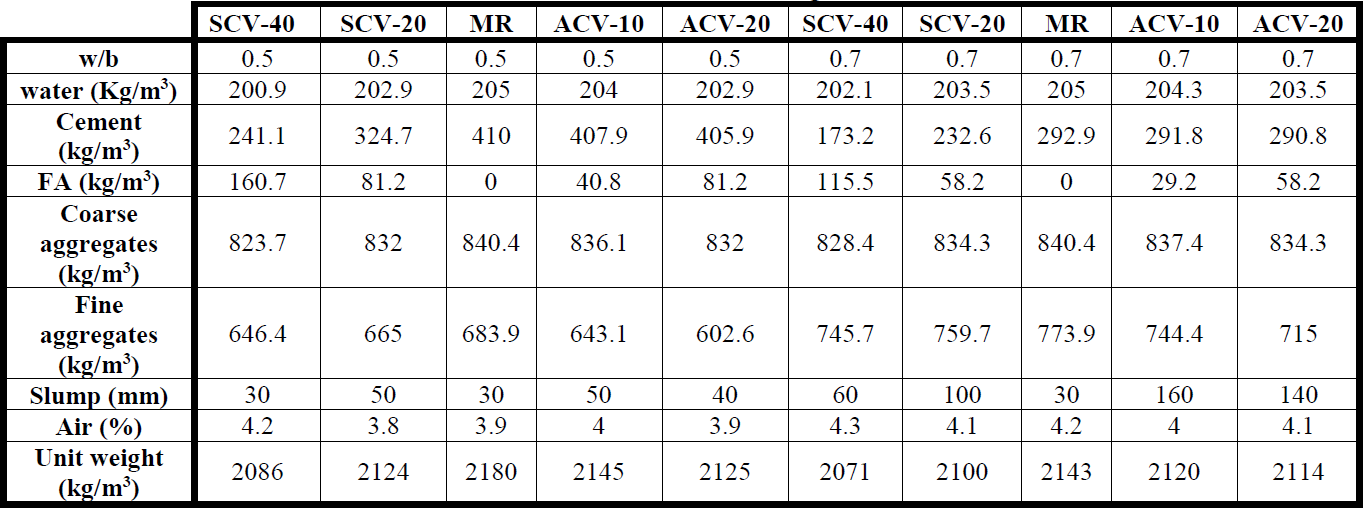

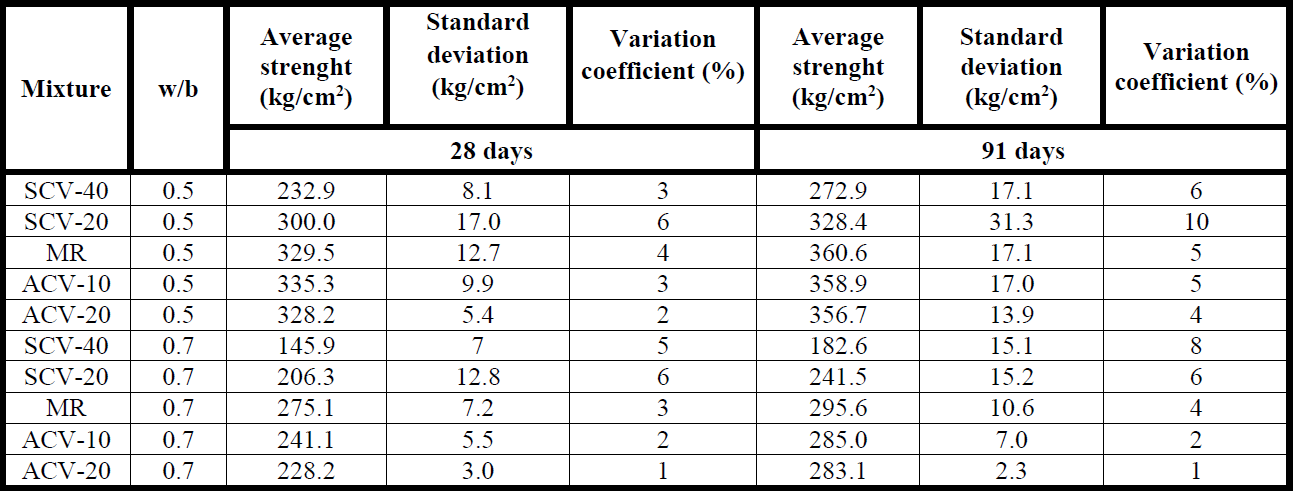

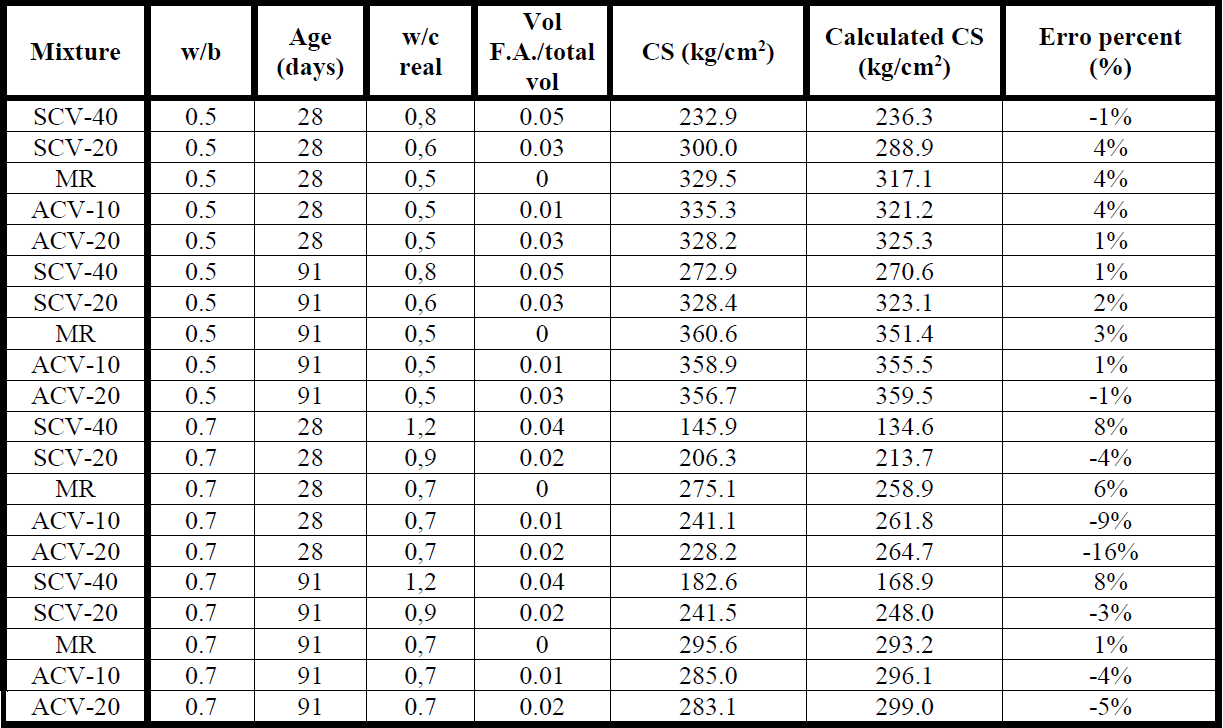

Mixtures design are given at Table 6 with aggregates in a saturated condition. Results in CS tests at 28 and 91 days, EM at 28 and 91 days and porosity at 91 days are given at Table 7, 8 and 9 correspondely.

4. DISCUSSION

Coarse aggregates did not satisfy with the particle size distribution recommended by ASTM C 33. It has unsufficient amount of 3/8” aggregate size due to a lack supervisión on the grinding proccess. Absorption value of coarse aggregates is high due to his porosity and low density. Fine aggregate satisfied with ASTM C 33 requierements. According with the Fineness Module, it is classified as a medium sand. However, the absorption and density are similar to coarse aggregate values. Fly ash satisfied the oxide composition with a 91.1% value, therefore is classified as a FA class C; also obtained a PAI of 75% at 7 days and 82% at 28 days according to ASTM C 618. Density of FA is lower than cement and aggregates; however, the measured value is within regular values as Neville mentioned at 1998. However, FA does not satisfied the fineness requirement to be considered as a Pozzolan within concrete because only 28.83% has the minimum particle size; however, grinding was not considered due to the main objective of use FA directly from the source and observe mechanical properties influence. When Fly ash is added as a mineral addition, a volume percent of fine aggregate is substituted. According to ASTM C 33, fly ash will increase the fineness amount in the concrete considering FA as a fine aggregate, however the fineness of FA proportioned an increase on packing within concrete. Image analysis from SEM (Figure 4) confirm the spherical shape particle of FA.

Volume of fine aggregate in mixtures decreased with fly ash addition both addition and substitution of portland cement (Figure 5) due to a difference of densitys between fly ash and portland cement. Fly ash occupies more volume than portland cement when this was substituted in mixtures. Therefore, an increase on cementitious volume paste and a decrease on fine aggregate volume result in raw materials saving.

Compressive Strenght on concrete specimens with w/b of 0.5, mixture ACV-10 reached a CS higher than 334.4 kg/cm2 (value recommended at ACI 211.1 at 28 days, no more mixtures reached the target CS. In concrete specimens of 91 years age, mixtures MR, ACV-10 and ACV-20 obtained higher CS than values recommended from ACI, however, mixtures ACV-10 and ACV-20 obtained less CS than the reference MR.

Compressive strength on all concrete specimens with w/b of 0.7 (except SCV-40) obtained a higher value than target value from ACI 211.1 of 200 kg/cm2 at 28 and 91 days age. Fly ash did not improve the CS in any mixture either substitution or mineral addition compared with reference mixture, therefore, the increase on compressive strength from 28 days to 91 days is due to cement. A correlation between w/b ratio, substitution/adition percent of cement by fly ash and concrete age was made through a variance analysis (ANOVA) to predict compressive strength of concrete (table 10). The independent variables were concrete age, real w/c ratio, volume relation of FA and total volume of mixture and dependet variable was compressive strength as is shown in Table 10. Through a multiple regression in ANOVA programa equation 1 was obtained.

Where: ƒ’ c = CS in kg/cm2, Age= Concrete age in days, w/c = real w/c ratio, Vol. F.A./m3 = Relation of FA volume per m3.

Table 10 Relation between concrete age, w/b ratio, real w/c, real FA volumen/total mixture volumen and compressive strenght

Considerations to use equation 1 are given in the following order:

Concrete has to be made with CPC 30R and Class F Fly ash

Curing regime of concrete should be with limewater for up to 28 days.

High absorption Crushed limestone Aggregates with nominal diameter of 3/4¨ should be used.

Concrete design should be made according to ACI 211 recommendations with the changes explained in “experimental details chapter” and concrete design to achieve a target slump between 7.5 and 10cm.

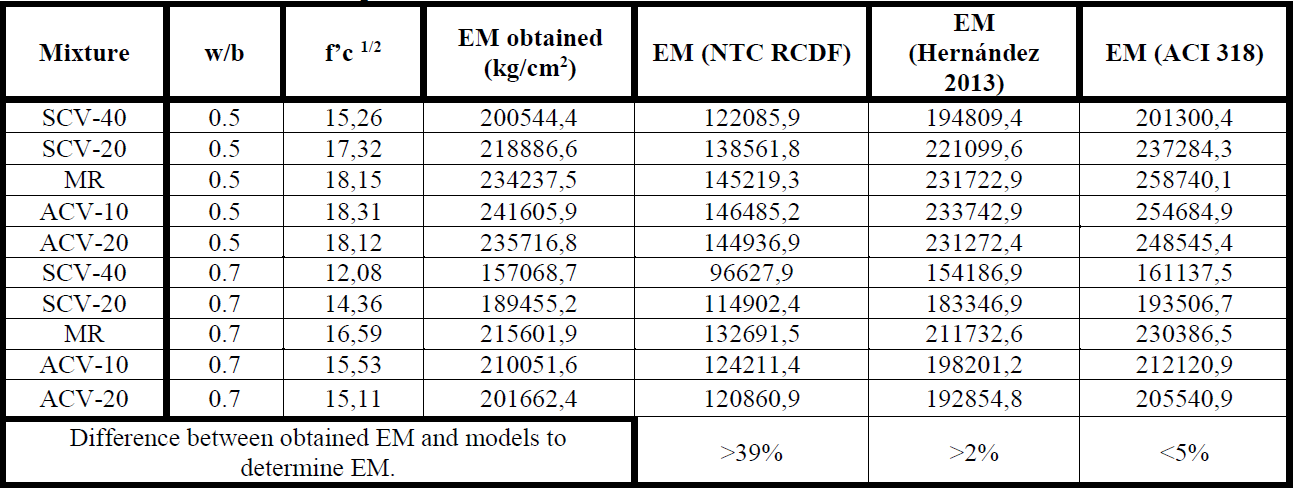

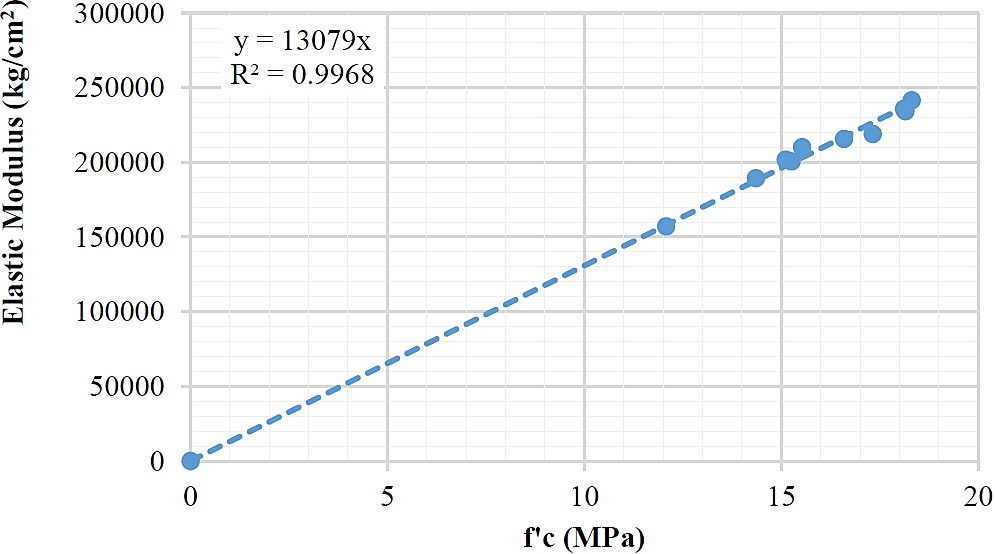

Elastic Modulus of each mixture were calculated according to Complementary Technical Standards of Norms Construcion from Federal District (NTC RDF spanish acronym) equations for class 2 concrete and volumetric weight lower than 2200 kg/m3 (equation 2), ACI 318 standard equations for concrete with unit weight between 1440 kg/ m3 and 2480 kg/m3 (equation 3) and equations from Facultad de Ingeniería of Universidad Autónoma de Yucatán (FIUADY) research made by Hernández at 2013, where a relation between aggregates density and square root of compressive strength was stablished to predict Elastic Modulus in concretes with HACLA (equation 4). Comparision of results are given in Table 11.

Where: E= EM en kg/cm2, Wc= Unit weight of concrete in kg/m3, f’c= CS in kg/cm2, GEAG = Specific gravity of coarse aggregate (SSS), GEAF = Specific gravity of fine aggregate (SSS), f’c (kg/cm2)= CS.

Correlation between obtained and calculated results with NTC-RCDF equations was made by calculating K function of Elastic Modulus obtained in experimental work with a lineal regression in Microsoft Excel. Consideration as f’c= 0 was taken to obtained a EM of 0 (Figure 6). This is shown in equation 5.

Where: E= ME in kg/cm2, f’c= RC in kg/cm2. Obtained equation has a K of 60% up than NTC RDF standards. Consequently, the use of NTC RDF equations allow overstating concrete structures design, then, regional standards should be done according to aggregates type.

Fly ash did not have a significant influence in Porosity, density and absorption results. However, it was observed a small increase of porosity when fly ash was added (Table 9).

Porosity is a main factor in mechanical properties and durability in concrete, the higher porosity is lower mechanical properties are obtained, resulting in a lack of durability performance in aggressive environments (Mehta & Monteiro, 1998). It was observed a tendence on compressive strength decrease when porosity increases (Figure 7) taking MR mixtures as a reference. However, porosity percents have a low variation range of +/- 4%. Only mixtures of cement substitution by Fly Ash obtained a significant decrease in compressive strength when porosity increases compared with MR mixtures. Experimental work from Solís and Moreno, 2011 concluded that porosity criateria in concrete with HACLA is not adecuaded to determine the quality of concrete. Relation between CS and Porosity results in this work seems to corroborate Solís & Moreno conclusions.

5. CONCLUSIONS

Class F Fly Ash from Nava, México is recommended to use in concrete with HACLA as an inert fine aggregate due to the following arguments:

Even if compressive strength was not increased by fly ash this remained

Fly ash concrete employment allows a usefulness to this material currently destined to environment affecting nearby urban zones.

According to mechanical properties results, the following conclusions were stablish:

A lack of Pozzolanic Activity from Fly ash was obtained, even when certain requierements were satisfied; fly ash was not able to enhance quality in concrete with HACLA. However, fly ash can be used adjusting mixtures design with equation 1 and 5 to maintain target CS and EM, even without modifications to fly ash such as grinding.

Equations 1 and 2 to determine CS and EM for concretes with HACLA were calculated to avoid overstating in concrete structures from Yucatán and optimize the raw materials.

Fineness of fly ash should be increase by grinding to enhance the pozzolanic activity and packing in concrete.

texto en

texto en