Serviços Personalizados

Journal

Artigo

Indicadores

-

Citado por SciELO

Citado por SciELO -

Acessos

Acessos

Links relacionados

-

Similares em

SciELO

Similares em

SciELO

Compartilhar

Revista ALCONPAT

versão On-line ISSN 2007-6835

Rev. ALCONPAT vol.7 no.2 Mérida Mai./Ago. 2017

https://doi.org/10.21041/ra.v7i2.189

Applied research articles

Low impact fiber reinforced material composite

1 Universidad Autónoma de Nuevo León, México.

This article investigates the mechanical behavior of fiber-reinforced cementitious composites using moderate to high contents of fly ash (FA) as a replacement for cement; the goal is to create primary building elements with low environmental impact. The experimental results showed that the compressive strength, modulus of elasticity, and post-cracking flexural strength for specimens with w/cm = 0.60 and 20% FA substitution increased with respect to the control. Moreover, the specimens with high FA substitutions had significantly lower mechanical strength values and elastic modulus values. The results indicate that it is feasible to use fiber-reinforced concrete composites as an alternative for low-environmental impact primary construction.

Keywords: fiber; cementitous; composites; fly ash, impact material

El presente texto expone los resultados del estudio del comportamiento mecánico de compuestos cementantes fibroreforzados utilizando consumos moderados y altos de ceniza volante (CV) en sustitución de volúmenes determinados de cemento (20%, 40% y 60%), con el objetivo de producir elementos constructivos primarios de bajo impacto ambiental. La experimentación realizada indicó que el esfuerzo a compresión, el módulo de elasticidad y la resistencia a flexión post agrietamiento, para los especímenes con relación a/mc = 0.60 y con 20% de sustitución con CV registraron incrementos en sus valores con respecto al control para ambas edades. No se evidenció deterioro en las mallas de fibras naturales por la exposición al medio alcalino. Los resultados hasta ahora obtenidos indican que es viable el uso de estos compuestos cementantes fibroreforzados como alternativa de construcción primaria de bajo impacto ambiental.

Palabras clave: fibra; cementicios; compuestos; ceniza volante; material de impacto

Este artigo apresenta algumas importantes propriedades mecânicas obtidas numa pesquisa de materiais cimentantes reforçados com fibras, nos quais foram utilizados consumos moderados e altos de cinza volante (fly ash, FA), em substituição ao cimento Portland (20%, 40% e 60%), com o objetivo de produzir elementos primários de baixo impacto ambiental. Os resultados experimentais mostraram que a resistência à compressão, o módulo de elasticidade e a resistência à flexão, aumentaram em relação ao de referência, para as misturas de a/cm = 0,60 e 20% de substituição. Para os demais casos de substituição foram encontradas resistências e módulo mais baixos que o de referência. Os resultados mostraram que pode ser viável o uso desses materiais cimentantes reforçados com fibras, como alternativa de construção primária de baixo impacto ambiental.

Palabras chave: fibra; cimento; compósitos; cinzas volantes; material de impacto

1. Introduction

The construction industry is increasingly focusing its projects towards a change in commitments and responsibilities in the way projects are constructed. Based on these ideas, the study of construction materials has intensified, leading many authors to question the meaning of sustainable construction (Ding, 2008), which is understood as the environmental impact of all processes implied during construction. These processes include the selection of materials to final disposal of material waste, and as a whole, the processes have a minimal impact to the environment.

In this context, one must also consider the location of buildings, their impact on the surroundings, energy consumption, and waste recycling after demolition of a building when its function or lifecycle has been fulfilled (Alfonso, 2003; Gundes 2016). Taking into account this definition, one should consider all the criteria for a sustainable design, which implies an analysis of the location, construction process, use, and demolition, with a simple goal of minimizing those circumstances that could degrade the environment at each of the aforementioned stages.

Building construction is a social demand. With the use of new materials and construction procedures that promise both low environmental and economic impacts, one might consider a possible solution to the imminent demand for basic housing from countries with emerging economies. Considering several approximate rates of growth, as those reported in the United Nations report for 2013 Population (Population Reference Bureau, 2014), it is expected that by the year 2050, the world will contain 9.6 billion inhabitants compared to the approximately 7.2 billion today where poor and developing countries will see the largest population increases (Population Reference Bureau, 2014).

This expected population growth implies that annually, housing must be offered to 65 million human beings. This growth implies the construction of several 15 million new housing units, which is on the order of 600 million square meters (40 m² per family) or the equivalent. This construction would require annually producing and using approximately 400 million cubic meters or approximately one billion tons of materials, components, and subsystems, which would be solely used for construction of new housing (Salas & Oteiza, 2008) using traditional construction materials. In addition, the increase in CO2, mass energy consumption, damage to the natural landscape, exploitation of natural resources, durability problems, and other factors to produce materials and construct these residential complexes must be considered. A proposal to develop alternative construction materials via production processes with low environmental impacts and low cost would solve the problem concerning global housing conditions (Alvarez Anton & Diaz, 2014).

2. Literature review

2.1 Materials with Low Environmental Impact

The use and reuse of alternative raw materials has become widespread around the world, with the goal of obtaining materials with low environmental impacts. Such is the case in Uruguay, where a construction system using blocks of soil cement fabricated with high compressive loads has been employed, resulting in high strength, excellent thermal insulation, and durability (Patrone, García & Nigro, 2005). In Venezuela, foundations are made of stone combined with dirt, roofs are made of wood, and for walls, so-called “bales of hay” covered with mixtures of lime or clay are used to protect them from external agents (Patrone, García & Nigro, 2005). In Cuba, the physical, mechanical and durability properties of concrete made with 25% and 100% of recycled coarse aggregates using active and inert additions, were determined. The results show that the recycled aggregate concrete made with active additions improved the durability of conventional concrete (Pavo, Etxeberría & Martínez, 2011).

In Chile, people have designed houses in which the foundations are made of stone on a structure of logs and tar placed within metallic meshes and covered with clay (Patrone, García & Nigro, 2005). In Mexico, dirt, lime, and Portland cement are used as stabilizers, and cactus mucilage and water mixing agents are used to fabricate compressed earth blocks (CEBs) with the goal of placing them in social-interest housing to reduce costs and CO2 emissions (Roux, 2010). In addition, studies have been performed on cementitious materials with low environmental impact that use fiber reinforcement that reduces the use of structural-reinforcement steel. In general, fibers can be classified according to their origin: natural (from stems or leaves), mineral (asbestos), and man-made (steel, glass, or polymer). Studies have been performed on the use of natural fibers as an alternative to mineral fibers to reinforce cementitious materials (Juárez, Valdez & Durán, 2004).

Therefore, the use of natural fibers that are considered green or environmentally friendly materials may be a viable option for the coming years. Natural fibers are also found all over the world, making their use as a reinforcement material in cementitious matrices an economical alternative with a low environmental impact in construction.

A study on the physical properties and morphology of these fibers is required to determine their feasibility as a reinforcement material (Pacheco-Torgal, Jalali, 2011; Jarabo, Monte, Blanco & Tijero, 2012). Over time, many contributions have been made in investigating the use of different natural fibers, such as coconut fiber, sisal, sugarcane bagasse, bamboo, palm, jute, and wood fiber, due to their abundance in certain regions of the world (Pacheco-Torgal, Jalali, 2011). In recent years, interest in the use of these fibers as reinforcement for cementitious materials has been growing. Several investigations have demonstrated that when used as reinforcements, they have properties that are comparable to and competitive with conventional reinforced concretes (Azis & Lee 1984; ACI, 1998).

In addition to using natural fiber as a substitute for steel reinforcement, the environmental impact of cementitious composites can be reduced by adding industrial waste materials as additives to cement, such as fly ash. The benefit of this substitution is reducing cement consumption, which is the primary component in concrete, because cement releases a significant amount of CO2 to the environment during its fabrication (USGS, 2015). The use of fly ash as a cement additive in concrete is widely justified for two reasons: the economic savings implied by the reduction in cement used and the microstructural changes caused by the substitution. Concerning the second point, there is consensus that ash generates a denser concrete and reduces the average pore size.

2.2 Aspects of Durability

It is necessary to consider the durability of low-environmental-impact material under service conditions. It has been observed that the partial substitution of Portland cement with fly ash at quantities on the order of 50% to 60% leads to cementitious materials with better durability performance (Malhotra, 2001). However, it is necessary to consider that the use of natural fibers within the cementitious matrix presents a series of problems related to their organic nature. Various studies have found that the natural fibers degrade when they are immersed in a cementitious matrix because the highly alkaline environment of the matrix dissolves the primary compounds of the fibers, such as lignin and hemicellulose, and consequently weakens their microstructure (Stancato, Burke & Beraldo, 2005; Sedan, Pagnoux, Smith & Chotard, 2008; Kriker, Bali, Debicki, Bouziane & Chabannet, 2008). Another factor to consider is the high absorption of natural fibers (Savastano, Warden & Coutts, 2005). To reduce the absorption of fibers, the use of organic substances to coat fibers has been reported, which thereby reduces the absorption percentage to approximately 4% (Alawar, Hamed, Al-Kaabi, 2009; Bilba & Arsene, 2008); another alternative is hornification (Claramunt, Ardanuy, García-Hortal & Filho, 2011).

An additional alternative to provide durability to cementitious materials with low environmental impact is to modify the alkalinity of the matrix by adding pozzolanic materials, such as fly ash, rice husks, or sugarcane bagasse (Agopyan, Savastano, John & Cincotto, 2005; De Gutiérrez, Díaz & Delvasto, 2005; Savastano, Warden & Coutts, 2003). However, it has been found that the use of these supplemental cementitious materials does not necessarily guarantee that the fibers do not degrade because the different compounds in the sample do not substantially reduce the alkalinity of the cementitious matrix (Mohr, Biernacki & Kurtis, 2007; John, 2005; Tonoli, Santos, Joaquim & Savastano, 2010). From this perspective, the objective of this research is to study the mechanical behavior of cementitious composites with low environmental impact that use natural fibers as reinforcement embedded in the binary matrix using different percentages of fly ash as a cement additive.

3. Experimental procedure

3.1 Materials

In this research project, natural fiber from the agave family, known as “Lechuguilla”, was used, with which a textile-like mesh can be formed. Additionally, CPC 30R Portland cement, Fly Ash (FA), and limestone aggregates at maximum sizes of 10 mm for the coarse aggregate and 4.75 mm for the fine aggregate were used. The FA is an artificial pozzolanic material, which comes from the Río Escondido plant located in Piedras Negras, Coahuila. The chemical composition of the FA and the cement is shown in Table 1. The FA was used in percentages of 20, 40, and 60% as an additive to cement for two different water/cementitious material ratios (w/cm), 0.60 and 0.70. The cement consumption was 350, 280, 210, and 140 kg/m3 for FA substitutions of 0, 20, 40, and 60%, respectively.

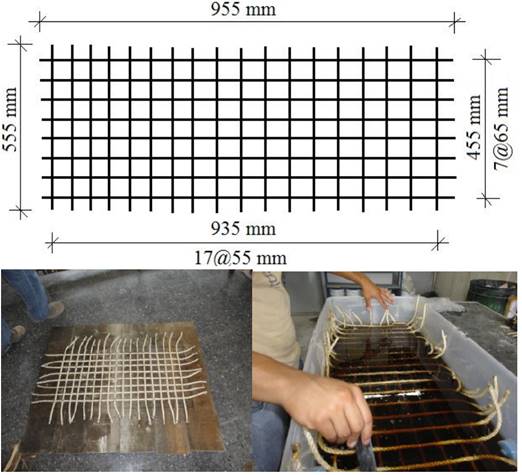

3.2 Mesh fabrication

The textile-like mesh made of natural fiber had dimensions of 955 x 555 mm. Figure 1 shows the general arrangement of the mesh. The joining of the longitudinal and transverse segments for the mesh was achieved using a polymeric adhesive applied at the points of contact. The adhesive was allowed to dry 24 h at a temperature of 23ºC in a laboratory environment. To protect the natural fiber from attack by the alkaline medium of the cementitious matrix, the fiber was impregnated with a paraffin-based substance. This step is necessary because the high alkalinity significantly damages lignin, which is the primary component of the natural fiber (Malhotra, 2001).

The mesh was placed in an oven at 100°C for 24 h to remove the moisture present in the fibers and obtain a dry state. Afterwards, the paraffin was melted at approximately 67ºC. The mesh was impregnated for 5 min and was subsequently left to dry at room temperature for 30 min. In addition to protection from the alkaline medium of the cementitious matrix, the coating causes the fiber to absorb significantly less moisture, which benefits the durability of the natural fiber significantly; consequently, the strength of the composite material is preserved.

3.3 Mixing, casting, and curing

Thirty-two panels reinforced with natural-fiber mesh with dimensions of 960 x 560 x 50 mm were fabricated in duplicate, and 48 concrete cylinders with dimensions of 100 mm diameter and 200 mm in height were created in triplicate. The proportions used in the concrete mixtures are indicated in Table 2. A concrete mixer with a 100-L capacity was used. The mixing of the concrete was performed in accordance with the ASTM C192 standard, and the slump test was performed according to the ASTM C143 standard. The casting and curing procedure was performed in accordance with the ASTM C31 standard.

Table 2 Proportions of the concrete mixtures (kg/m³)

| w/cm | 0.6 | 0.7 | ||||||

|---|---|---|---|---|---|---|---|---|

| 0% | 20% | 40% | 60% | 0% | 20% | 40% | 60% | |

| Materials | ||||||||

| Water | 299 | 299 | 299 | 299 | 263 | 263 | 263 | 263 |

| Cement | 350 | 280 | 210 | 140 | 350 | 280 | 210 | 140 |

| FA | 0 | 70 | 140 | 210 | 0 | 70 | 140 | 210 |

| Coarse | 705 | 698 | 690 | 682 | 667 | 659 | 652 | 644 |

| Fine | 1055 | 1043 | 1032 | 1020 | 998 | 986 | 975 | 963 |

| Slump (mm) | 90 | 105 | 115 | 130 | 235 | 245 | 255 | 265 |

The casting of the fiber-reinforced panels was performed in two layers, each approximately 25 mm thick. The first layer was compacted by applying 15 strikes with a rubber mallet on the lateral faces of the wood falsework. Afterwards, the mesh was placed by hand in the middle of the panel thickness and then compacted on a vibration table for 1 minute. For the second layer, the same casting and compacting procedure as the first layer was performed. The mesh was kept in the middle part of the thickness; the mesh was finished by leveling the surface.

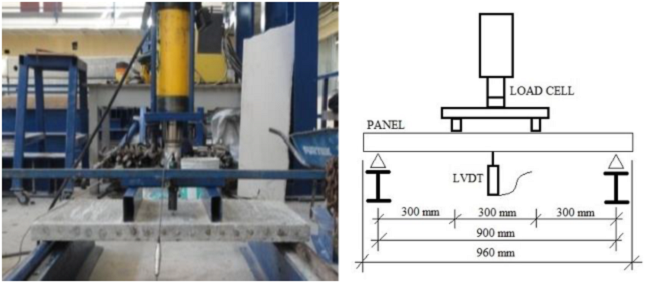

3.4 Mechanical tests

Mechanical tests on the fiber-reinforced panels and concrete cylinders at two ages, 2 and 4 months, were performed for each w/cm ratio. The concrete cylinders were tested in compression according to ASTM C39, and the elastic modulus was obtained in accordance with ASTM C469 at the ages established and for different FA percentages. In the same way, the panels of the fiber-reinforced concrete were subjected to flexural testing by applying a load in thirds to the panel. The free span distance between supports was 900 mm. The deformation was measured at the center of the span using a displacement transducer (LVDT). The data were captured with a data-acquisition system. Figure 2 shows the set-up for the flexural testing used on the panels.

4. Analysis and discussion of results

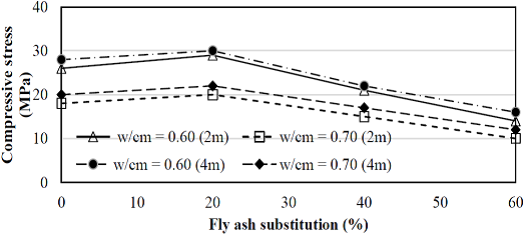

4.1 Compressive stress and elastic modulus

Figure 3 shows the effect of FA substitution on the compressive strength obtained for concrete cylinders with an FA substitution of 20%. The result shows that the concrete maintains essentially the same value as the control for both w/cm ratios and at ages of 2 and 4 months. The w/cm ratio has a significant effect on the increase in stress for 20% FA and for the control; however, for substitutions with 40% and 60% FA, the stresses decrease with respect to the control. In addition, the w/cm ratio and age do not appear to have a significant effect.

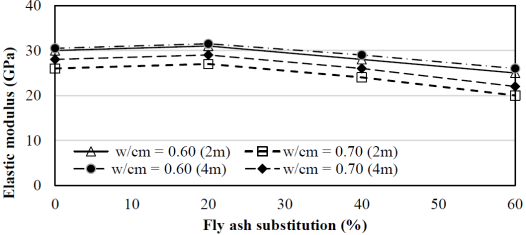

A similar mechanical behavior can be observed for the elastic modulus, though as shown in Figure 4 the w/cm ratio does not significantly increase the modulus for any percentage of FA at same testing age (Shen, Shi, Zhu, Duan & Zhang, 2016), (Siddque, 2004). The substitution of 20% FA continues to maintain at least the same value in comparison with the control.

In agreement with the experimental results, for the compressive stress and elastic modulus, the specimens with w/cm = 0.60 and with 20% FA substitution maintained the control values and even increase to 24 and 15% for both ages, respectively.

As is known, FA causes a pozzolanic reaction with the calcium hydroxide present during the hydration reactions of the cement, which contributes to the mechanical strength of the cementitious matrix when substitutions are relatively low; this reaction requires a certain amount of water from the w/cm ratio. Moreover, when high percentages of FA substitution are used in place of cement, the amount of calcium hydroxide present in the mix also decreases. It is possible that aluminosilicates from the FA lack a sufficient amount of calcium hydroxide for the pozzolanic reaction, and together with the low amount of cement, a reduction in its mechanical strength occurs. It can be assumed that the rest of the FA interacts with the matrix more as a filler than as a cementitious material. Previous studies on the mechanical behavior of specimens with FA substitution at relatively low percentages have shown adequate mechanical behavior, which was verified in this investigation (Durán-Herrera, Juárez, Valdez & Bentz, 2011), (Siddique, 2004).

4.2 Flexural stress on the panels

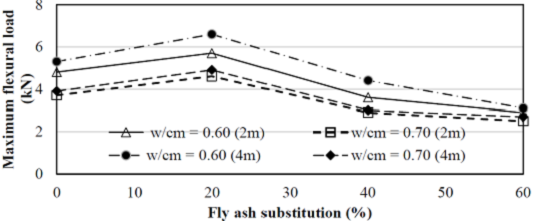

Figure 5 shows the effect of FA and age on the flexural strength of the fiber-reinforced concrete panels. It can be observed that the two w/cm ratios provide similar behavior. With an FA substitution of 20%, at 2 and 4 months of age, there are increases in the flexural strength of 20% and 25%, respectively, compared with that the control specimens. In contrast, for FA substitutions of 40 and 60%, a decrease in strength is observed with respect to the control, which is congruent with results found under compression and for the elastic modulus, in which the substitution of cement by 20% FA for both w/cm ratios and both ages improved the mechanical behavior. Figure 5 shows that the age seems to have insignificant effect on the gain in flexural strength, primarily for w/cm = 0.70.

Figure 5 Failure load behavior under flexural testing with respect to % FA at 2 and 4 months of age.

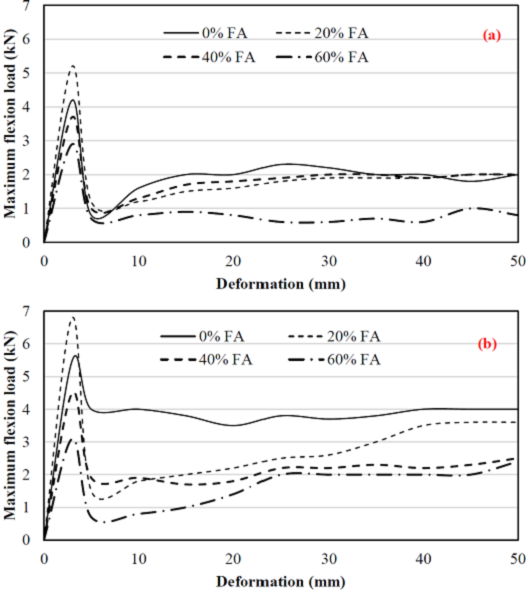

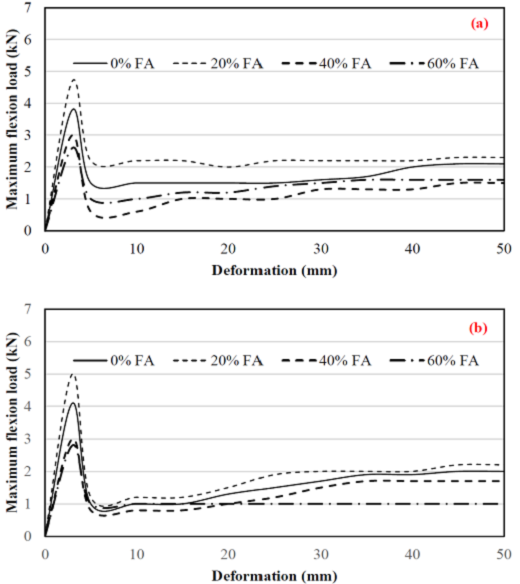

Figures 6 and 7 show the contribution to the flexural strength of the cementitious matrix, and the natural-fiber mesh as reinforcement for the panel. The contribution of the mesh alone occurs when the cementitious matrix reaches the maximum cracking load, and unloading rapidly follows. Figure 6 shows that the control specimens undergo an increase in the post-cracking load; Figure 7 shows that specimens with 20% FA exhibited a better post-cracking behavior. Moreover, the panels with high FA substitutions (40% and 60%) had a significant reduction in the post-cracking load with respect to the maximum flexural load that the panel could withstand before cracking (Bernal, De Gutierrez, Delvasto & Rodriguez, 2010).

The addition of the natural fiber mesh as a reinforcement in the concrete panels first contributed by improving the behavior in the fresh state of the concrete by impeding cracking by plastic contraction. Once the concrete hardened, the mesh reinforcement modified the brittle fracture mode of the concrete itself by contributing to its ductility (Sahib Banyhussan, Yildrim, Bayraktar, Demirhan & Sahmaran, 2016). Figures 6 and 7 show that the mesh induced a ductile behavior in the panel, where in several cases, the load recovered even though the maximum cracking load had not reached. In accordance with the results obtained, 20% FA substitution resulted in the highest flexural cracking load for both w/cm ratios and both ages. It was also observed that the load increased to 10% at 4 months of age compared with that at 2 months in the majority of the cases.

After the specimens at the two corresponding ages had been subjected to flexural testing, there was no evidence of degradation in the natural fibers caused by exposure to the alkaline medium during the aging period. This result was physically verified because the mode of failure of all specimens tested was ductile. The effect of different humidity and/or temperature conditions that are related to the deterioration of the natural fibers and that generate a brittle fracture mechanism (Juárez, Durán, Valdez & Fajardo, 2007), should be further studied to determine the feasibility of long-term use of this type of mesh-based reinforcement (Georgiou & Pantazopoulou, 2016), which would permit its application as new alternative construction materials.

5. Conclusions

The following are the primary conclusions of the study:

1. For the compressive stress and elastic modulus, the specimens with w/cm = 0.60 and 20% FA maintained the control value and even resulted in increases of 24 and 15%, respectively, for both ages teste.

2. Substitutions of 40% and 60% FA exhibited lower values of compressive stresses and elastic moduli with respect to the control; in addition, using these percentages of substitutions, the w/cm ratio and age did not appear to have a significant effect.

3. Control specimens and those with 20% FA exhibited better post-cracking behavior in flexural testing for both w/cm rations and both ages. Moreover, the panels with high FA substitutions (40% and 60%) had a significant reduction in the post-cracking load with respect to the maximum flexural load that the panels withstood before cracking.

4. The natural-fiber mesh reinforcement modified the brittle fracture mode of the concrete by contributing to its ductility.

5. There was no evidence of deterioration of the natural-fiber meshes due to exposure to the alkaline medium during the 2 and 4 months of testing during the flexural testing, which permits the assumption that the paraffin coating that was used was adequate.

6. The fiber-reinforced composites with 20% FA could be considered adequate for application as primary elements in building construction because they exhibited adequate mechanical behavior in compression and flexion. However, the specimens with 40% FA and 60% FA are not recommended for application in these elements.

REFERENCES

ACI Manual of Concrete Practice, Part 5, (1998). State of-the-Art on Fiber Reinforced Concrete. ACI Committee 544. [ Links ]

Agopyan, V., Savastano, H., John, V. M., Cincotto, M. A. (2005). Developments on vegetable fibre-cement based materials in São Paulo, Brazil: an overview. Cement and Concrete Composites, 27(5), 527-536. doi:10.1016/j.cemconcomp.2004.09.004. [ Links ]

Alawar, A., Hamed, A. M., Al-Kaabi, K. (2009). Characterization of treated date palm tree fiber as composite reinforcement. Composites Part B: Engineering, 40(7), 601-606. doi:10.1016/j.compositesb.2009.04.018. [ Links ]

Alfonso, C. (2003). La vivienda del siglo XXI: edificación sostenible. Ambiental: Revista del Ministerio de Medio Ambiente, (23), 22-28. [ Links ]

Alvarez Anton, L., Díaz, J. (2014). Integration of life cycle assesment in a BIM environment. Procedia Enginnering, 85, 26-32. [ Links ]

Aziz, M. A., Lee, S. L. (1984). Concrete Reinforced with Natural Fibers. Surrey, R. N., Ed. New Reinforced Concretes, Oxford: University Press, 106-140. [ Links ]

Bernal, S., De Gutierrez, R., Delvasto, S., Rodriguez, E. (2010). Performance of an alkali-activated slag concrete reinforced with eteel fibers. Construction and building Materials, 24, 208-214. doi:10.1016/j.conbuildmat.2007.10.027. [ Links ]

Bilba, K., Arsene, M. (2008). Silane treatment of bagasse fiber for reinforcement of cementitious composites. Composites Part A: Applied Science and Manufacturing, 39(9), 1488-1495. doi:10.1016/j.compositesa.2008.05.013. [ Links ]

Claramunt, J., Ardanuy, M., García-Hortal, J. A., Filho, R. D. T. (2011). The hornification of vegetable fibers to improve the durability of cement mortar composites. Cement and Concrete Composites, 33(5), 586-595. doi:10.1016/j.cemconcomp.2011.03.003. [ Links ]

De Gutiérrez, R. M., Díaz, L. N., Delvasto, S. (2005). Effect of pozzolans on the performance of fiber-reinforced mortars. Cement and Concrete Composites, 27(5), 593-598. doi:10.1016/j.cemconcomp.2004.09.010. [ Links ]

Ding Grace, K. C. (2008). Sustainable construction - The role of environmental assessment tools. Journal of Environmental Management, 86, 451-464. [ Links ]

Durán-Herrera, A., Juárez, C. A., Valdez, P., Bentz, D. P. (2011). Evaluation of sustainable high-volume fly ash concretes. Cement Concrete Composites, (33)1, 39-45. [ Links ]

Georgiou Antroula, V., Pantazopoulou Stavroula, J. (2016). Effect of fiber length and surface characteristics on the mechanical properties of cementitious composites. Construction and Building Materials, 125, 1216-1228. http://dx.doi.org/10.1016/j.conbuildmat.2016.09.009 [ Links ]

Gudes, S. (2016). The use of life cycle techniques in the assessment of sustainability. Procedia - Social and Behavioral Sciences, 216, 919-922. [ Links ]

Jarabo, R., Monte, M. C., Blanco, A., Negro, C., Tijero, J. (2012). Characterisation of agricultural residues used as a source of fibres for fibre-cement production. Industrial Crops and Products, 36(1):14-21. doi:10.1016/j.indcrop.2011.07.029. [ Links ]

John, V. M. (2005). Durability of slag mortar reinforced with coconut fibre. Cement and Concrete Composites, 27, 565-574. doi:10.1016/j.cemconcomp.2004.09.007. [ Links ]

Juárez, C. A., Valdez, P. L., Durán, A. (2004). Fibras Naturales de Lechuguilla como Refuerzo en Materiales de Construcción. Revista Ingeniería de Construcción. Santiago: Escuela de Ingeniería Pontificia. Universidad Católica de Chile, 19 (2): 83-92. [ Links ]

Juárez, C., Durán, A., Valdez, P., Fajardo, G., (2007). Performance of “Agave Lecheguilla” natural fiber in Portland cement composites exposed to severe environment conditions. Building and Environment, 42 (3), 1151-1157. [ Links ]

Kriker, A., Bali, A., Debicki, G., Bouziane, M., Chabannet, M. (2008). Durability of date palm fibres and their use as reinforcement in hot dry climates. Cement and Concrete Composites, 30(7), 639-648. doi:10.1016/j.cemconcomp.2007.11.006. [ Links ]

Malhotra, V. M., (2001). High-performance, high-volume fly ash concrete for sustainability. P.-C Aïtcin Symposium on the Evolution of Concrete Technology, Sherbrooke: Université de Sherbrooke, 19-74. [ Links ]

Mineral Commodity Summaries. (2015). U.S. Geological Survel. Virginia, USA. [ Links ]

Mohr, B. J., Biernacki, J. J., Kurtis, K. E. (2007). Supplementary cementitious materials for mitigating degradation of kraft pulp fiber-cement composites. Cement and Concrete Research, 37(11), 1531-1543. doi:10.1016/j.cemconres.2007.08.001. [ Links ]

Pacheco-Torgal, F., Jalali, S. (2011). Cementitious building materials reinforced with vegetable fibres: A review. Construction and Building Materials, 25(2): 575-581, doi:10.1016/j.conbuildmat.2010.07.024. [ Links ]

Patrone, A., García, B., Nigro, E. (2005). Muro monolítico con suelo estabilizado. Construcción con Tierra1, Buenos Aires: Universidad de Buenos Aires, (1), 60-65. [ Links ]

Pavon, E., Etxeberria, M., Martinez, I. (2011). Properties of recycled aggregates concrete using active and inert addictions. Revista de la Construcción [online], 10(3), 4-15, doi.org/10.4067/S0718-915X2011000300002. [ Links ]

Population Reference Bureau (2014), World population data sheet. (n.d.) Retrieved from ) Retrieved from http://www.prb.org/pdf14/2014-world-population-data-sheet_eng.pdf . [visited 19.10.14]. [ Links ]

Roux, R. (2010). Los bloques de tierra comprimida en zonas húmedas, México: Plaza y Valdés. [ Links ]

Salas, J., Oteiza, I. (2008). Los materiales de construcción ante las ingentes necesidades de hábitat en el tercer mundo (Carencias de una investigación necesaria). II Jornada de Investigación en Construcción. (p. 463), Madrid: Instituto de Ciencias de la Construcción Eduardo Torroja. Consejo Superior de Investigaciones Científicas. [ Links ]

Sahib Banyhussan, Q., Yildirim, G., Bayraktar, E., Demirhan, S., Sahmaran, M. (2016). Deflection-hardening hybrid fiber reinforced concrete: The effect of aggregate content, Construction and Building Materials, 125, 41-52. http://dx.doi.org/10.1016/j.conbuildmat.2016.08.020 [ Links ]

Savastano, H., Warden, P. G., Coutts, R. S. P. (2005). Microstructure and mechanical properties of waste fibre-cement composites. Cement and Concrete Composites, 27(5), 583-592. doi:10.1016/j.cemconcomp.2004.09.009. [ Links ]

Savastano, H., Warden, P., Coutts, R. S. (2003). Potential of alternative fibre cements as building materials for developing areas. Cement and Concrete Composites, 25(6), 585-592. doi:10.1016/S0958-9465(02)00071-9. [ Links ]

Sedan, D., Pagnoux, C., Smith, A., Chotard, T. (2008). Mechanical properties of hemp fibre reinforced cement: Influence of the fibre/matrix interaction. Journal of the European Ceramic Society, 28(1), 183-192. doi:10.1016/j.jeurceramsoc.2007.05.019. [ Links ]

Shen, D., Shi, X., Zhi, S., Duan, X., Zhang, J. (2016). Relationship between tensile Young´s modulus and strength of fly ash high strength concrete at early age. Construction and Building materials,123, 317-326. http://dx.doi.org/10.1016/j.conbuildmat.2016.06.145 [ Links ]

Siddique, R. (2004). Performance characteristics of high-volume Class F fly ash concrete. Cement and Concrete Research, 34,487-493. [ Links ]

Stancato, A. C., Burke, A. K., Beraldo, A. L. (2005). Mechanism of a vegetable waste composite with polymer-modified cement (VWCPMC). Cement and Concrete Composites, 27(5), 599-603. doi:10.1016/j.cemconcomp.2004.09.011. [ Links ]

Tonoli, G. H. D., Santos, S. F., Joaquim, A. P., Savastano, H. (2010). Effect of accelerated carbonation on cementitious roofing tiles reinforced with lignocellulosic fibre. Construction and Building materials, 24(2), 193-201. doi:10.1016/j.conbuildmat.2007.11.018. [ Links ]

Received: March 16, 2017; Accepted: May 27, 2017

texto em

texto em