We want to express our utmost respect and gratitude to the emeritus SNI researchers who have contributed significantly to the field of electrochemistry in Mexico. Dr. Yunny Meas Vong, Dr. Joan Genescá Llongueras, Dr. Ignacio González Martínez, Dr. Jorge Ibañez Cornejo, Dr. Omar Solorza Feria, and Dr. Elsa Miriam Arce Estrada have worked tirelessly and with a scientific passion for promoting new knowledge that benefits our environment and society. Their legacy serves as an inspiration to future researchers in the noble field of electrochemistry, as well as to us.

Introduction

Steel is a crucial industrial material used for many years ago to manufacture pipes, machinery, structures, and tools; unfortunately, its degradation occurs due to corrosion, a significant problem that generates costly economic losses and irreversible damage [1]. Therefore, preventing and controlling this phenomenon is essential when developing a monitoring or maintenance plan. A promising solution to mitigate corrosion is using green inhibitors [2, 3]; these innovative inhibitors contain organic molecules extracted from organic plants, leaves, or fruits that suppress oxidation-reduction reactions when steel is exposed to aggressive environments such as acidic media. Depending on the type of metal-media interaction, green inhibitors can generate protective layers (thin film inhibitors) or work through an adsorption process, in which a charge transfer occurs between the inhibitor and the metal surface, forming a protective layer that prevents contact with the metal, in addition, they offer essential economic advantages, as they are relatively inexpensive and environmentally friendly [4-6]. Organic plant extracts contain phytochemical compounds, including heteroatoms such as sulfur, phosphorus, nitrogen, and oxygen, which effectively prevent metal corrosion; these heteroatoms act as adsorption centers, allowing easy adsorption on the metal surface. Several plant and fruit extracts have been studied, showing a high inhibition efficiency in different corrosive environments reaching inhibition efficiency of 80 to 96 %; some of them are Morinda Citrifolia leaves, Aloe vera gel, Opuntia Ficus, Pomegranate, among others [7-11].

The Citrus X-Latifolia plant (known as Persian lemon) is cultivated around the world, and Mexico is one of the leading exporters of this fruit; it belongs to the Rutaceae family along with the Citrus X-aurantifolia plant of which studies have been conducted to evaluate and characterize the corrosion inhibition capabilities in carbon steels in acid medium from the extract prepared with its leaves, according to Rajesh H. et al. [12] found efficiencies (IE) higher than 90% using low concentrations of the extract. At the same time, Rifat Mohammed Dakhil R.M. et al. [13] reported that efficiencies of 80 % are maintained with increasing temperature; therefore, it is of great interest to evaluate the leaves of Citrus X-Latifolia as a possible corrosion inhibitor for AISI 1045 steel exposed in an acidic medium H2SO4 (0.5 M) under standard conditions and implementing the use of electrochemical characterization techniques such as Electrochemical Impedance Spectroscopy (EIS) and Potentiodynamic Polarization (Tafel) to determine the corrosion rate (Vcorr) generated when different concentrations of this extract are added.

Another reason for considering using the leaves of the Citrus X-Latifolia plant instead of its fruits is that the leaves are often discarded, leading to waste accumulation and environmental pollution, thus representing an opportunity to explore alternative uses for this resource, particularly in the corrosion of materials.

Experimental

Preparation of extract and acid.

The leaves of Citrus X-Latifolia were collected, washed with soap, and rinsed with distilled water to be later dehydrated naturally, taking advantage of sunlight (this process lasted about three months), once dried they were crushed in a mortar until obtaining fine particles that were weighed on a balance until getting 50 gr of powder that was poured into a flask and filled with 500 ml of ethanol; finally, this solution was macerated for two weeks before being used in the tests. The concentrations in ppm of the Citrus X-Latifolia extract used were: 40, 80, 120, 160, 200, 240, 280, 320, 360, and 400, this process is shown in Fig. 1 [7, 13]. For the corrosive medium, a solution of H2SO4 (0.5 M) was prepared from concentrated acid and distilled water.

Specimens preparation

For AISI 1045 steel specimens, cylindrical bar coupons were cut and shaped into samples 2.5 cm in diameter and 1 cm in width; the chemical composition of this steel is Si 0.22 %, Mn 0.75 %, S 0.50 %, P 0.40 %, C 0.40-0.50%, and balance Fe. The samples were then abraded using different sizes of silicon carbide paper with the numbers: #80, #240, #300, #400, #600, and #1200 until achieving a mirror finish with an alumina cloth. After polishing, the samples were washed with water, soap, and acetone and dried with hot air. Finally, the specimens were kept in a desiccator for testing.

Electrochemical evaluation

For corrosion test, acrylic cells were manufactured on a milling machine (a particular cell designed by DR.3H) [7, 9], to which 10 mL of H2SO4 (0.5 M) were added. The cell has a configuration of 3 electrodes: 2 are connected at the top, the reference electrode (RE) of Ag/AgCl (KCl sat.), and a graphite bar as the counter electrode (CE), while at the bottom steel is found below as a working electrode (WE) [14], this assembly can be seen in Fig. 1. A Parstat 4000 potentiostat/galvanostat from Prince Applied Research® (serial number 14181860) linked to a PC and controlled by Versa Studio software for acquisition data was used for experimentation. The sequence described in Fig. 2 begins with the test of the steel exposed to acid, applying open circuit potential (OCP) for 1 hour to monitor the equilibrium potential of the system, later EIS technique is used with a sweep of frequencies ranging from 100KHz at 10mHz, with an amplitude of 10 mV with 10 points/decade, at the end Tafel was applied, with a sweep potential of ± 250 mV, and a sweep speed of 1.66 mV/s [15-17]. Once this first sequence of tests was finished, the first extract concentration of 40 ppm was added, and the OCP, EIS, and Tafel techniques were applied again. This process will be repeated by adding each dosage within the same test.

Metallic surface and extract characterization

Functional groups present in the Citrus X-Latifolia extract were analyzed using FT-IR infrared spectroscopy; for this purpose, a Perkin Elmer Spectrum 100 FTIR unit, equipped with a universal ATR sampling accessory and applying a wave number of 400-4000 cm-1. Metallographic images were taken to assess the impact of the inhibitor extract on the steel surface using an OLYMPUS brand Inverted Metallurgical Microscope GX51; the captures correspond to different stages, the initial state of the steel, after exposure to H2SO4 (0.5 M), and after tests with inhibitor extract.

Results and discussion

FT-IR results

The FT-IR spectrum obtained from the Citrus X-Latifolia extract is shown in Fig. 3; 5 signals are detected: a peak located at 3323 cm-1 identified as the presence of an OH group, at 2926 cm-1 related with the stretching vibration (asymmetric) of the C-H group, the peak located at 1608 cm-1 is related to an H-O-H group, the 1724 cm-1 peak is characteristic of a carboxylic functional group (-COOH), finally, in the peak located at 1039 cm-1 related to the stretching vibration of the C-O bond attributed to carbohydrates (sugars and starch). These functional groups contain heteroatoms (P, O, S, N), which have an electron density that promotes their adsorption on the steel surface through coordinated bonds.

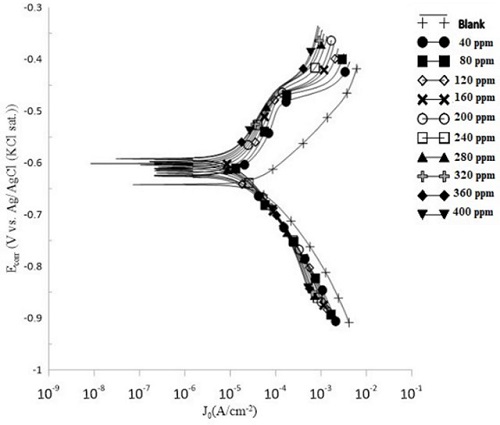

Potentiodynamic polarization curves (TAFEL)

The results of the potentiodynamic polarization curves are shown in Fig. 4; it can be observed a marked change in the corrosion potential (E corr ) between the anodic curve of the steel in 0.5 M H2SO4 (Blank) concerning the curves generated from the concentrations of the inhibitor extract, it is also noted a change in the shape of the anodic slope related to a decrease in the exchange current density (J o ) when the inhibitor is added. The shift of the potential towards more positive values (nobler) and the shape of the curves with the inhibitor comply with the behaviour of an anodic type inhibitor, according to Sastri S.V. [4], this type of inhibitor forms a film that adsorbs on the surface of the steel, preventing its dissolution.

Fig. 4 Potentiodynamic polarization curves for AISI 1045 in H2SO4 (Blank) and Citrus X-Latifolia Inhibitor.

The anodic (b a) and cathodic (b c ) Tafel slopes of the polarization curves with blank and inhibitor concentrations were calculated using the EC-Lab software by Bio-Logic®. The obtained values were substituted into the Stern-Geary expression (equation 1) to get the Polarization Resistance (R P ) and corrosion rate (V corr ); the results are summarized in Table 1.

Table 1 shows the results of the potentiodynamic polarization technique; in general, a decrease in the potential and the corrosion current is observed as each of the concentrations of Citrus X-Latifolia extract is added; on the other hand, these current values promote a better corrosion rate of 0.19 mm/year with a concentration of 360 ppm.

Table 1 Potentiodynamic polarization results for different doses of Citrus X-Latifolia extract in H2SO4 (0.5 M).

| Inhibitor concentration (ppm) | Ecorr (V vs. Ag/AgCl KCl sat.) | Icorr(A/cm2) | Vcorr(mm/y) | IE% |

| Blank | -0.640 | 1.55× 10-5 | 0.174 | - |

| 40 | -0.622 | 4.38× 10-6 | 0.049 | 71.83 |

| 80 | -0.623 | 3.83× 10-6 | 0.043 | 75.36 |

| 120 | -0.617 | 3.07× 10-6 | 0.034 | 80.27 |

| 160 | -0.612 | 3.31× 10-6 | 0.037 | 78.72 |

| 200 | -0.608 | 2.82× 10-6 | 0.032 | 81.84 |

| 240 | -0.603 | 3.02× 10-6 | 0.034 | 80.56 |

| 280 | -0.599 | 2.56× 10-6 | 0.029 | 83.54 |

| 320 | -0.598 | 2.26× 10-6 | 0.025 | 85.43 |

| 360 | -0.592 | 1.69× 10-6 | 0.019 | 89.14 |

| 400 | -0.590 | 2.15× 10-6 | 0.024 | 86.16 |

Electrochemical impedance spectroscopy (EIS)

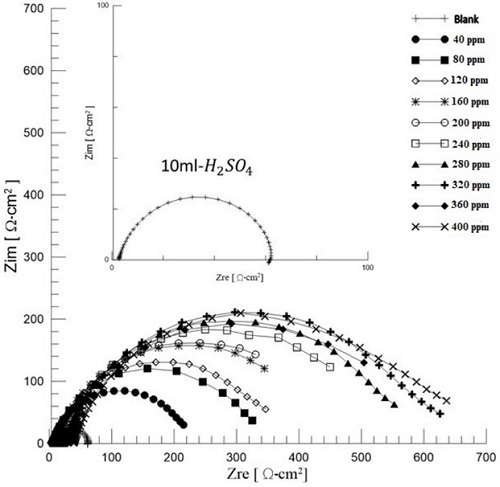

The resistive behavior of AISI 1045 steel exposed to 0.5 M H2SO4 and various concentrations of Citrus X-Latifolia extract was recorded using the EIS technique. Fig. 5 shows the Nyquist diagrams (Z re VS Z im ), which present a semicircular shape whose size increases as the inhibitor concentrations are added, indicating a remarkable increase in the resistance to R ct charge transfer between the steel in acid and as the inhibitor concentrations are added.

Fig. 5 Nyquist plots corresponding to AISI 1045 in H2SO4 (Blank) and the results of Citrus X-Latifolia extract.

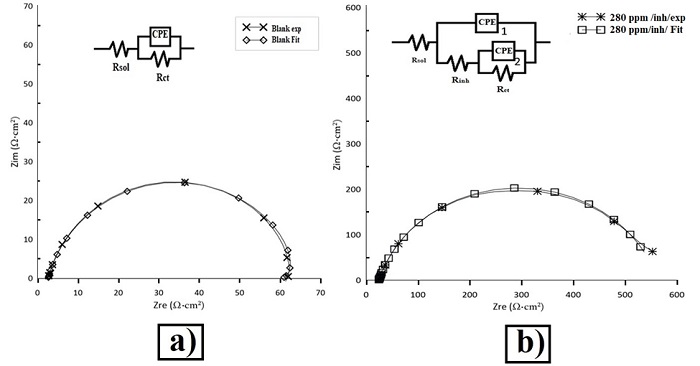

To calculate the electrical parameters of EIS, the Nyquist diagrams were adjusted using an equivalent electrical circuit (EEC) using Zsim® software. Fig. 6(a) shows the fit of the AISI 1045 steel in H2SO4; the EEC fitted to the semicircle shape was a Randles type [18] and consisted of two resistors; the solution resistance (R sol ), the charge transfer resistance R ct and a constant phase element (CPE) which replaces the electrochemical double layer capacitance (C dl ) and is expressed in units of µF; the estimation of C dl is carried out employing expression 2, this model is used to simulate the physical-chemical processes analogously when a metal is in contact with a corrosive medium; however, when adding the inhibitor the Randles model does not generate a good fit, so a different circuit was proposed which is shown in Fig. 6(b) where the modification of the EEC can be seen by integrating three resistors: solution Resistance (R sol ), inhibitor Charge transfer Resistance (Rinh) and Steel Charge Transfer Resistance (R ct ), as well as two CPE constant phase elements.

Where: ωθmax is the maximum frequency in the Nyquist semicircle, and the exponent a is a constant obtained by fitting and whose values range from 0.5 ~ 0.9. [18, 19]

Fig. 6 Fitted Nyquist diagrams and equivalent electrical circuit (EEC) representation corresponding to (a) AISI 1045 in H2SO4 (0.5 M), (b) AISI 1045 in H2SO4 (0.5 M) + Citrus X-Latifolia leaf extract, example of 14 mL added.

The results reported in Table 2 show the values for R sol , R ct , C dl , and finally the efficiency in percentage IE. It can be observed that the addition of 40 ppm of the inhibitor generates an increase in R ct , as well as an increase in capacitance, which suggests that the exchange of electrons between the medium and the steel decreases due to the formation of an insulating barrier on the surface of the metal, however, according to study from Bryan H. et al. [20], which suggests that the thickness of the film formed is related to the capacitance value, so that the higher the value of C dl , the lower its thickness, which implies that the thickness created by the Citrus X-Latifolia extract is not large and continues to permeate the corrosive ions of the medium in smaller quantities.

Table 2 Corrosion parameters obtained from Electrochemical Impedance Spectroscopy.

| Inhibitor concentration (ppm) | Icorr(A/cm²) | Rsol(Ω·cm²) | Rct(Ω·cm²) | Cdl(μF/cm²) | IE% |

| Blank | 4.23× 10-5 | 2.63 | 320.18 | 238.27 | - |

| 40 | 5.83× 10-6 | 3.31 | 1140.07 | 586.00 | 71.92 |

| 80 | 8.26× 10-6 | 6.30 | 1662.98 | 805.11 | 80.75 |

| 120 | 7.10× 10-6 | 9.21 | 1760.32 | 897.33 | 81.81 |

| 160 | 6.81× 10-6 | 12.31 | 2092.87 | 957.31 | 84.70 |

| 200 | 5.99× 10-6 | 15.17 | 2157.93 | 966.03 | 85.16 |

| 240 | 5.78× 10-6 | 20.02 | 2508.26 | 981.51 | 87.23 |

| 280 | 4.84× 10-6 | 24.07 | 2731.06 | 1077.80 | 88.28 |

| 320 | 4.01× 10-6 | 28.60 | 2980.51 | 1064.75 | 89.26 |

| 360 | 3.20× 10-6 | 34.54 | 2942.40 | 1205.00 | 89.12 |

| 400 | 4.01× 10-6 | 39.26 | 3008.73 | 1066.85 | 89.36 |

Fig. 7 presents the corrosion rates for both the Tafel and EIS techniques. The results reveal a substantial decrease in V corr for the steel sample when exposed to Citrus X-Latifolia doses compared to a blank sample. The lowest V corr values were obtained at a concentration of 360 ppm, with Tafel showing 0.019 mm/year and EIS showing 0.035 mm/year. Overall, the results obtained from both techniques are very similar, indicating a strong correlation between Tafel and EIS.

Inhibitor efficiency

Corrosion Inhibition Efficiency (IE) can be calculated using the coverage degree "θ" which represents the value of the covered metal surface from the inhibitor extract, the equations used in this investigation are shown below:

Where i corr is the corrosion current obtained from Tafel, and R ct is the charge transfer resistance obtained from EIS, using equations 3 or 4, the value of IE (%) can be calculated easily with expression 5 [12, 21]. Fig. 8 shows that the efficiency of the inhibitor was very promising, from 120 ppm with 80 % IE from both techniques and reaching 89 % IE at the final concentration of 320 ppm.

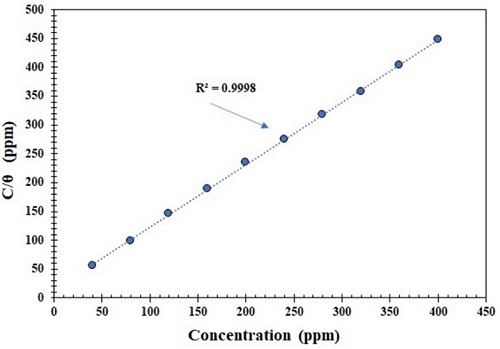

Adsorption mechanism

The modeling of adsorption isotherms is beneficial in providing information on the ability of the organic molecule of the inhibitor to concentrate on the metal surface. There are two adsorption mechanisms: physical adsorption (physisorption) and chemical adsorption (chemisorption). The physisorption is carried out by interactions of Van Der Waals forces between the active sites of the metal surface; such adsorbed molecules require energy values below -20 kJ/mol to form multilayers. While the chemisorption process, the interactions involve charge exchange and analogous force-coordinated bonding between the metal surface and the adsorbed molecules. Between the metal surface and the organic molecules, this monolayer formation requires energies above -40 KJ/mol.[7, 22-25]

With equations 3 or 4, it is possible to perform the calculation for different adsorption models; the most used in the literature is the Langmuir model, which is calculated using the following expression:

where C is the concentration of the inhibitors in the bulk electrolyte, K ads is the adsorption equilibrium constant.

In Fig. 9, equation 6 can be interpreted as an equation of the straight line; which shows that the behavior of Citrus X-Latifolia extract tends to be linear, and the correlation coefficient approaches 1; using the slope value, the Gibbs adsorption free energy (∆𝐺°𝑎𝑑𝑠 ) can be estimated by 7:

Fig. 9 Langmuir Isotherm representation for adsorption of Citrus X-Latifolia on AISI 1045 Surface exposes in 0.5 M H2SO4 at 25 °C.

Thermodynamic results obtained from analyzing the Langmuir isotherm's linear fit are presented in Table 3. The negative Gibbs energy (∆𝐺° ads ) value (-3.04 kJ/mol) indicates that the Citrus x Latifolia extract undergoes spontaneous adsorption on the AISI 1045 metal surface through a physisorption process. This behavior is similar to other organic molecules like Lime Juice, Opuntia Ficus Indica extract or synthetic inhibitors such as pantoprazole used in hydrocarbon pipelines [26-29].

Table 3 Isothermal parameters results of Citrus X-Latifolia leaf extract on AISI 1045 surface in H2SO4 at 25 °C.

| Isotherm | Intercept | Slope | Kads | R² | ΔGads (kJ· mol-1) |

| Langmuir | 14.53 | 1.08 | 0.06 | 0.99 | -3.04 |

The attack on the surface of the steel after the experimentation was recorded in Fig. 10, where the polished steel before the electrochemical tests is shown (Fig. 10(a)); after the exposure with 0.5 M H2SO4, the presence of pitting is observed, including the formation of oxide residues on the surface (Fig. 10(b)); finally, it can be observed in Fig. 10(c) that Citrus X-Latifolia extract obtained good results changing the type of corrosion since the inhibitor molecules obey an adsorption mechanism thus forming an organic barrier on the surface of the steel, corresponding to a decrease in the corrosion rate.

Conclusions

The extract prepared from Citrus X-Latifolia leaves is a suitable corrosion inhibitor for AISI 1045 steel against 0.5M H2SO4 solution under standard conditions. The electrochemical results using Tafel show that the behavior of this inhibitor is an anodic type and modifies the corrosion potential towards more noble values. In contrast, EIS measurements show that charge transfer resistance increases as each extract concentration is dosed, finding comparative corrosion rates for both techniques. The best efficiency observed in EIS and Tafel was 89 % under a concentration of 360 ppm. Finally, Langmuir adsorption isotherm shows that the extract uses a physical adsorption mechanism (physisorption) and creates a protective layer on the steel.

nueva página del texto (beta)

nueva página del texto (beta)