Nomenclature:

| BPO | Bael pyrolytic oil |

| ASTM | American Society for Testing and Materials |

| FTIR | Fourier Transform Infrared Spectroscopy |

| GC-MS | Gas Chromatography coupled with Mass Spectrometry |

| BTE | Brake Thermal Efficiency |

| BSEC | Brake Specific Energy Consumption |

| CR | Compression Ratio |

1. Introduction

The share of biofuels will be 8% of fuel demand for road transport and their utilization will reach 4.6 million BOE per day by 2040 from the value of 1.3 million BOE per day in 2012 (Singh et al., 2015). High fuel economy, stable and simple structure of Diesel engines are the reasons for their applications as the major propulsion power source for both marine and inland transportation and power generation (Alahmer, 2013). Hence the need of the hour is to explore the hidden potentials of biofuels. Biofuels are types of hydrocarbons that are generated from organic substances in a brief period, in contrast to conventional fossil fuels which are formed over trillions of years. The three categories of biofuels are (i) first generation fuels, (ii) second generation fuels and (iii) third generation fuels. The origins of first generation biofuels are substances like sugar, starch, animal fats and vegetable oil, in short, edible oils obtained from sources like corn, soybean, mustard, olive, etc. (Sakthivel et al., 2018). Ethanol and biodiesel are some important first generation biofuels that are used in transport applications in some countries. These fuels emit lesser greenhouse gases (GHG) compared to their fossil counterpart but have certain disadvantages like inferior cold flow properties and substandard oxidation stability. A major drawback is that energy expenses incurred while producing crops and converting them to biofuels is more than the energy gained from biofuels. A study from Cornell University observed that nearly 30% more energy is invested in producing ethanol from corn than that released from the biofuels. The bio-fuel derived from non-edible sources falls under the category of second generation fuel. Even though these second generation fuel does not directly compete with the food supply chain, they tend to affect the cultivation of edible sources. Thereby, second generation fuels also affect the food supply chain. Third generation fuels offer a solution to the problems posed by the first and second generation fuels. They are considered greener, help in waste management and do not have a negative impact on the food supply as they are generated from sources such as microalgae, fish oil, waste frying oil, pyrolysis oil etc. (Sakthivel et al., 2018). Third generation fuels are extracted using various conversion technologies. Pyrolysis has attracted researchers due to its features such as simple procedure, limited waste, low operating pressure, and high conversion efficiency. Pyrolysis is the thermochemical decomposition of biomass at high temperatures (300 - 600 °C) without air (and oxygen) in the reactor to produce pyrolytic oil, char and non-condensable gas. Pyrolysis oil is an intricate mixture that contains a variety of organic groups, like esters, carboxylic acids, aldehydes, alcohols, phenols, ketones, furans, alkenes, syringols and guaiacols. The advantage is that it can be stored till it is required for utilization or easily transported to places where it can be most effectively used. What makes pyrolytic oil a challenging fuel for utilization in modern combustion engines are factors like low calorific value, high viscosity, high acidity and low thermal stability. After upgradation and refining, these pyrolysis oils can be mixed with diesel and used in compression ignition (CI) engines. Many researchers (Alagu & Sundaram, 2018; Doğan et al., 2012; Pradhan et al., 2017; Rajamohan & Kasimani 2018; Rajamohan et al., 2021; Sharma & Murugan, 2013; Volli et al., 2014; Yang et al., 2013) have studied this and reported a remarkable increase in brake thermal efficiency. Prakash et al. (2013) conducted a thorough study using a CI engine charged with pyrolytic oil obtained from waste wood-biodiesel emulsions and discovered that the BTE of 5%, 10% and 15% blends were higher than that of diesel by 0.5%, 4.75% and 7.4% at maximum load. The authors also found a significant decrease in NOx emission by 2.5%, using a 15% blend at full load. Pradhan et al. (2017) performed experiments with the oil derived from the thermal cracking of Mahua seed, in CI engine and concluded that 30% blend may be employed in CI engine for improved performance. Volli et al. (2014) employed mustard cake oil blends to fuel a compression ignition engine and concluded 4.7% higher BTE and decreased exhaust emissions for 30% blend when compared to straight diesel.

Using biodiesel in CI engines, researchers reported the CR effect on the emission, combustion and performance attributes because higher CR generally improves the air-fuel ratio (AFR) by increasing the density due to higher temperature and pressure of the molecules in the combustion chamber. Higher CR also shows an augmentation in maximum in-cylinder pressure and in rate of blazing of the fuel-air mixture. Hariram and Shangar (2015) carried out experiments using a CI engine to establish the effect of CR on combustion and performance attributes and concluded that a CR of 18 gave better BTE and BSEC for diesel. Muralidharan and Vasudevan (2011) studied the characteristics of a CI engine without any modification, using waste cooking oil blends and found that a blend of 40% of waste cooking oil has higher BTE than diesel at higher CR. The authors also found that the HC emission levels rise with elevation in CR, the specific fuel consumption of the engine using B40 blend is less than that of other blends at higher CR, and the waste oil blends result in peak pressure during combustion at high CR. El_Kassaby and Nemit_allah (2013) analyzed the influence of CR on an engine charged with biodiesel from waste oil fuel and concluded that nearly 20 % blend of biodiesel can be employed safely at any CR and speed to obtain performance and emission similar to diesel fuel. The authors also deduced that the engine fuelled with biodiesel was advantageous over diesel at higher CR. Nagaraja et al. (2015) conducted experiments to analyze the effect of CR on the attributes of CI engine with variable CR charged with diesel blends using preheated palm oil and noticed a reasonable reduction in the emission levels of CO and HC for all blends at higher CR and maximum load. The authors proved with the experimental results that a lesser concentration of preheated palm oil could be considered as a good alternative for neat diesel. Kommana et al. (2016) studied the performance and emission using palm kernel and eucalyptus blends in VCR-CI engine and concluded that B15 (85% palm kernel oil + 15% eucalyptus oil) is capable of replacing the conventional petroleum based diesel. At full load condition, the authors observed a marked reduction in CO by 41%, HC by 42%, NOx by 9% and smoke by 37% for B15 blend at a CR of 19:1. Sivaramakrishnan (2018) investigated the engine characteristics by using Karanja fuel blends in a VCR engine and noted 30.46% BTE for B25 blend at maximum load at CR of 18, which is 5% higher than diesel. He found that the HC emission of blends was lower than diesel. Overall, he stated that when compared with diesel the performance of B25 blend was better at 18 CR. Hirkude and Padalkar (2014) investigated the performance and emission attributes of CI engines operated with Waste fried oil (WFO) methyl ester blend. They inferred that with the rise in CR, the BTE increases for all blends, the emission of CO reduces and the NOx emission increases. The authors proved that at high CR the performance of existing agricultural engines with WFO blends is enhanced. Channapattana et al. (2015) tested the use of Honne oil biodiesel blend as fuel in a DI CI-VCR engine. They concluded that the engine should be operated at a CR of 16 to 18 and CR of 18 resulted in higher NOx emissions while the other emissions found reduced. The studies conclude that the understanding of the effect of CR on the attributes of diesel engine is important when the new fuel blend is used for its operation.

Sharma and Murugan (2015) studied the behaviour of DI diesel engine using tyre pyrolysis oil-diesel blend at different CR’s and concluded that it greatly influences the combustion and performance parameters of CI engines like BTE, BSEC and combustion attributes etc. The previous literature studies show that 20% of pyrolytic oil could be blended with diesel which gives performance similar to that of diesel without making any modification to the engine. To the best of the author's knowledge, no momentous research has been reported, analyzing the effect of CR on operating characteristics of diesel engines powered with pyrolytic oil obtained from biomass. The characteristics of Bael pyrolysis oil, investigations on storage stability, its suitability for the operation of CI engine, optimization and exergy analysis were reported in the literature (Paramasivam et al, 2018; 2019; 2019a; 2020). From the experimental results, it was found that F20D is recommended as the greater fuel blend regarding the greater fuel stability and for better engine operating characteristics. The authors appreciate the work done reported and the present research work has been dedicated to conducting a detailed study to discover the right CR which gives the optimum performance of diesel engine fuelled with a blend of diesel and Bael pyrolytic oil. A blend was prepared with 20% pyrolytic Bael oil and 80% diesel and the succeeding investigations were performed. The performance, combustion and emission characteristics of VCR engine using the blend at CR’s of 16, 17.5 and 18, for all loads, at standard conditions were studied and compared with the results of standard diesel at a CR of 17.5.

2. Material and methods

2.1. Characterization of raw material

The RHA steel plates Bael tree is commonly found in India, Nepal and Myanmar. The leaves, fruit, stem and roots of the plant are known to have medicinal value. The seeds of the fruit are processed for the extraction of oil. The leftover cake does not serve any purpose hence it is wise to employ this feedstock for pyrolysis.

Bael de-oiled cake (Fig. 1) was procured from a local firm. To gauge the quality of fuel derived from the pyrolysis of the cake, it is necessary to perform elemental analysis. Proximate analysis was done as per ASTM D 3172-07a and Ultimate analysis which provides a picture of the elements present in the feedstock was performed as per ASTM D5291-96 using Perkin-Elmer Series II 2400 CHNS/O Elemental Analyser.

2.2. Production of BPO

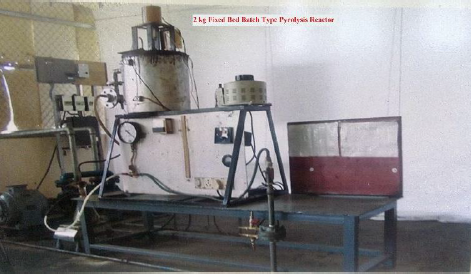

A fixed bed reactor (Fig. 2) was utilized for performing the pyrolysis of the cake. The reactor vessel had a capacity of 2 kg and the electrical heater had a rating of 250Vand 9.5A. The reactor vessel was filled with 2kg of the de-oiled cake and sealed completely using a Polytetrafluoroethylene (PTFE) gasket to prevent any gases from escaping to the surrounding. The reactor core temperature was set as 600°C with a low heating rate of 10°C/min. The reactor core temperature was controlled by a PID controller coupled with a K-type thermocouple. Once the temperature of 600°C was attained, it was maintained at the same temperature until the release of gas stops. The condensable portion was collected in a conical flask by allowing gases evolved to pass through a condenser and the non-condensable gases were left out. The experiment was terminated when the flow of gasses stopped which was found using a soap bubble test. The oil collected was filtered to remove any fine particles of char by using a filter paper. The obtained pyrolytic oil is centrifuged at 10,000 rpm for 20 min by adding sodium sulphate to separate the aqueous and organic phase. The separated organic phase is employed in the present work as the alternative fuel source.

2.3. Production of BPO Blend

An emulsion is described as a concoction of two or more insoluble liquids. By bringing down the surface tension of the liquids, surfactants help in making the mixture stable. The blend of 20% vol. Bael pyrolytic oil and 80% vol. neat diesel was prepared by emulsification using two non-ionic surfactants namely Span 80 and Tween 80. The prepared blend was stored in room temperature for 24 hours and no phase separation was observed ensuring the stability of the blended fuel.

2.4. Characterization of BPO

Only after determining the properties of the Bael pyrolytic oil, can the decision of blending it with diesel be made. So various physical properties like kinematic viscosity, density, pH, fire point, and flash point were determined by following the procedures mentioned in ASTM D4052, ASTM E70, ASTM D445, ASTM D93B, ASTM D93B respectively. A bomb calorimeter was utilized to evaluate the calorific value of the oil as per ASTM D240.

2.5. Engine experimental setup

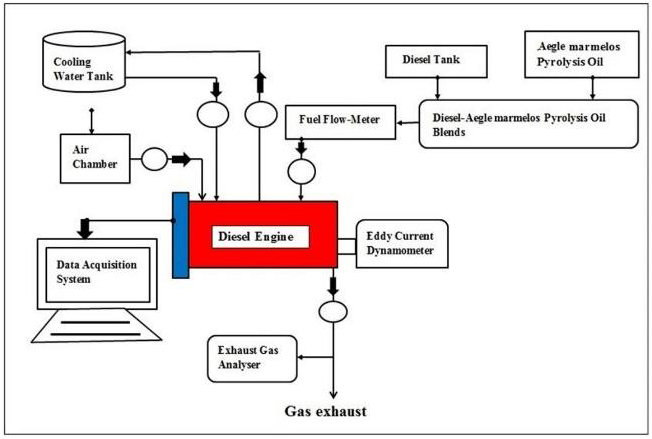

A single-cylinder, direct injection, water cooled, diesel engine linked with eddy current dynamometer, as shown in Fig. 3 was utilized for conducting the experiments. A power output of 3.5 kW at a speed of 1500 rpm was produced by the engine.

The engine specifications are presented elsewhere (Rajamohan & Kasimani, 2018). The tests were performed at standard injection timing and compression ratio. The engine featured a mechanical fuel injection system with an injection pressure of 200-210 bar [16]. The nascency of fuel injection was set at 23°bTDC. To measure the mass flow rate of the fuel consumed a burette with automatic solenoid control was used. A piezoelectric pressure sensor with a charge amp was employed for pressure analysis. A Crank angle encoder was employed in the data acquisition system for motor angle measurement.

The exhaust gas temperature was measured by thermocouple arrangement (K-Type). An AVL Modular Diagnostic System (MDS-250) exhaust gas analyzer was used to gauge the exhaust emission such as carbon monoxide, carbon dioxide, nitrogen oxides and unburnt hydrocarbons. The NOx and HC exhaust were analyzed in ppm, and the CO2 and CO were measured in percentage volume. Every run was carried out at a steady speed of 1500 rpm but with differing loads. Initially, the engine was run in diesel fuel for about 20 minutes at no load condition. After which, the engine was operated with BPO blend (20%) at 16, 17.5 and 18 CR at different loads by progressively increasing the load. At each load, the engine was kept running for five minutes to attain stability. At the sixth minute, the fuel consumption and all other parameters were recorded. The compression ratio was varied when the engine was in running condition by changing the tilt angle of the specifically designed tilting block arrangement. The engine was checked for adequate water flow and lubricating oil level prior to its operation. The engine parameters were analyzed at three CRs using the blend, and the obtained results were compared with diesel at a standard CR of 17.5.

2.6. Uncertainty analysis

The confidence that can be placed on the results can be determined only by uncertainty analysis. Uncertainty refers to the degree of goodness of the results. To ensure the dependability of the readings obtained, Error Analysis or uncertainty analysis is necessary. The instrument details, their accuracy and uncertainties are listed in Table 1.

Table 1 Parameters, accuracy and uncertainties used in this study.

| Instruments used |

Parameters measured |

Accuracy | Uncertainty |

|---|---|---|---|

| Engine testing | BTE | ±0.5% | ±0.05 |

| BSEC | ±0.05 MJ/kW h | ±1 | |

| Emission testing | CO | ±0.01 volume % | ±2 |

| CO2 | ±0.03 volume % | ±0.5 | |

| HC | ±1 ppm | ±2 | |

| NOx | ±1 ppm | ±2 |

The total uncertainty of the trials was calculated as ±3.64% by the principle of propagation of errors.

3. Results and discussion

3.1. Characterization of Bael pyrolytic oil

The Pyrolytic oil obtained from the outlet of the condenser appeared dark brown in colour and contained diverse compounds with varying molecular weights. Physical properties such as kinematic viscosity, calorific value, density, fire point, flash point were found to be within the limit proposed by ASTM and are given in Table 2. Caution should be exerted while moving the biofuel from one place to another so that fire-related accidents owing to the lower flash point can be avoided. The high viscosity of the oil may cause difficulty during fuel injection and atomization.

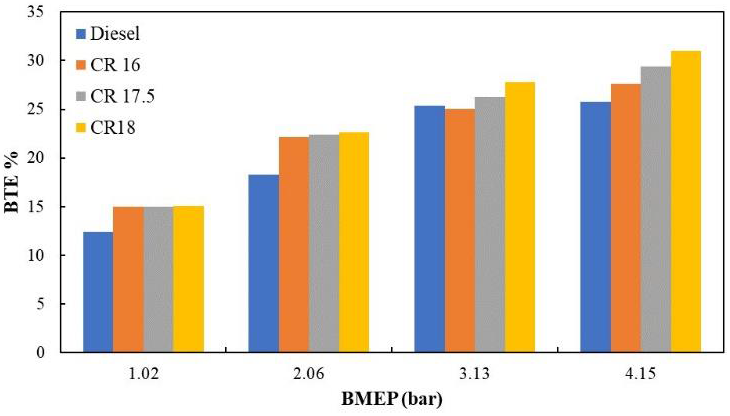

3.2.1. BTE

BTE is a factor that expresses how efficiently the chemical potential present in the fuel is transformed into positive work. The chemical energy added is a product of the mass of fuel being injected and its heating value. A well-established fact is that the BTE is directly proportional to CR. At elevated CR the temperature of charge rises which consequently results in enhanced combustion of the injected fuel. The changes in BTE with BMEP is given in Fig. 4.

It is clear that the BTE augments with raise in load as the rise in power output and drop in heat loss is observed at higher loading conditions (Sharma & Murugan, 2015). At 100% load, the BTE of diesel at compression ratio 17.5 and BPO20 at a compression ratio of 16, 17.5 and 18 are 25.87%, 27.73%, 29.52% and 31.1%. At a CR of 18, the blend has a maximum efficiency of 31.1% which is nearly 20% higher than neat diesel. This can be attributed to the enhanced mixing phenomena caused by the micro explosions of the internal fuel droplets owing to the differences between the volatility of bio-oil and diesel thereby causing secondary atomization at higher CR (Qi et al., 2017). The BTE of the blend at CR of 17.5 and 16 is 6% and 11% less than BTE at maximum compression ratio. At higher CR, the ignition delay is reduced which enhances the performance causing the observed trend (Raheman & Ghadge, 2008).

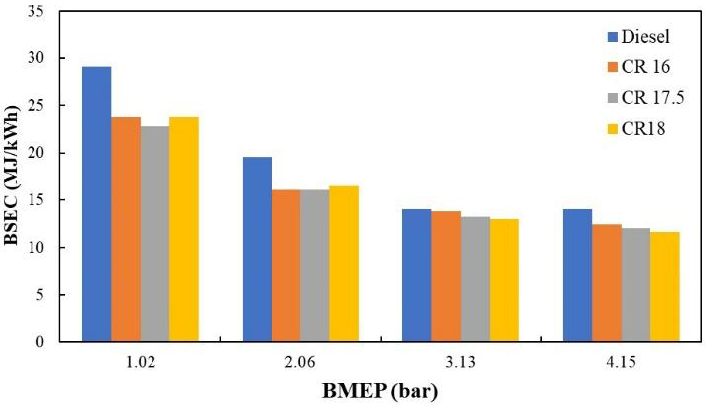

3.2.2. BSFC

BSFC is the effectiveness by which the energy content of the fuel is transformed into positive work. This engine index indicates the fuel economy, unlike brake thermal efficiency. Nevertheless, it is not advisable to employ the term, when fuels with dissimilar densities and calorific values are to be compared (Rajamohan & Kasimani, 2018; Sharma & Murugan, 2013).

Instead, when comparing blends of fuels, BSEC is utilized, which is defined as the product of BSFC and calorific value. From Fig. 5, it is apparent that the BSEC is lower at elevated compression ratio at higher loads. At maximum loading conditions, the BSEC of diesel is 13.92 MJ/kWh. The BSEC of the blend at compression ratios of 16, 17.5 and 18 are 12.4, 12 and 11.6 MJ/kWh respectively. As the BTE increases at higher CR, accordingly the BSEC decreases and the observed trend follows this principle. At a compression ratio of 18, the blend consumes 16.6% less energy compared to base fuel. The presence of oxygenated species along with finer atomization at high CR enhances the combustion process thereby reducing the heat loss and paves way for reduced energy consumption (Cheng et al., 2008). Also, higher CR improves the extent of evaporation which in turn enhances the combustion process thereby reducing the fuel consumption (Sharma & Murugan, 2015).

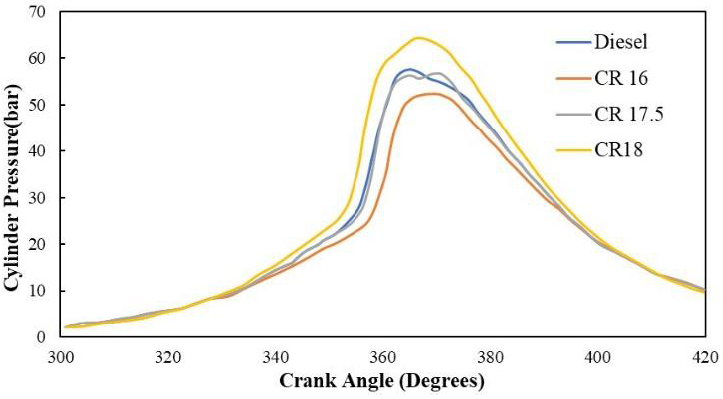

3.3.1. In-cylinder pressure history

The capacity of fuel to mingle effectively with air and burn is characterized by cylinder pressure (Doğan et al., 2012). In-Cylinder pressure, exerts influence on the engine attributes. The pressure in an engine cylinder varies throughout the engine cycle. Fig. 6 shows the difference of cylinder pressure trace with respect to crank angle for base diesel and blend at all compression ratios.

Smooth engine operation without any knocking was observed at all compression ratios for blend and 17.5 CR for diesel. The maximum or peak pressure attained in the cylinder relies on the pace of fuel combustion at the early stage. The peak pressure for neat diesel and blend at a CR of 17.5 is 57.64 bar and 56.85 bar recorded at 365 CA° and 370 CA° respectively. It is obvious from the pressure trace that at this CR, combustion commences prior for diesel as compared to that of blend owing to its higher cetane index than the blend. At maximum load, the peak cylinder pressure for pyrolytic oil blend at 16 and 18 compression ratios are 52.59 bar and 64.22 bar respectively. Very apparent from the figure is the augmentation in maximum cylinder pressure with a hike in CR. This augmentation may be attributed to the fact that a hike in CR proportionally augments the temperature of air intake thereby providing superior atomization and mixture formation which in turn accelerates the combustion of fuel droplets (Nagaraja et al., 2012). The enhancement in maximum in-cylinder pressure at CR 18 is 11.4% in comparison to diesel. This enhancement is due to the faster-premixed combustion phase at higher compression ratios (Sharma & Murugan, 2015).

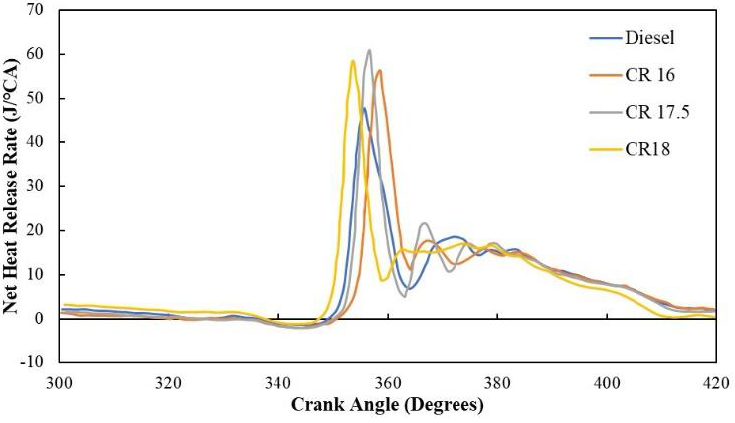

3.3.2. Net heat release rate (HRR)

HRR is the sum of all the changes of internal energy of the cylinder gases and the work done on the piston without taking into account the heat transmitted to the combustion chamber walls (Heywood, 1988). The quantity of heat liberated in the premixed combustion of compression ignition engine is determined by factors like ignition delay, calorific value and rate of mixing of fuel with an oxidizer (Sharma & Murugan, 2013). The heat input into the diesel engine can be calculated using the HRR study established from the cylinder pressure data. By applying the first law of thermodynamics to the pressure vs crank angle data as suggested by Heywood (1988) and Pradhan et al. (2017).

Where dQ/dӨ denotes the HRR (J/CA), P is the pressure (bar), V is the volume of the cylinder and γ represents specific heat ratio.

The relationship between HRR and crank angle is given in Fig. 7. The cooling effect produced by fuel vaporization during the delay period makes the HRR negative in the initial stage (Alagu & Sundaram, 2018; Yang et al., 2013). The HRR of diesel and the blend at 16, 17.5 and 18 compression ratios are 47.83, 56.36, 57.4 and 58.44 J/CA°.

The HRR curve for diesel lied under the HRR curves for the blend at all CR. This can be due to the lesser ignition delay of diesel which leads to lesser fuel accumulating in thereby lesser fuel burnt in the premixed phase of combustion. The peak HRR of the blend at 18 CR is 3.6% higher than that of the blend at 16 CR which is 56.36 J/CA°. A higher compression ratio caused an enhancement in the HRR due to reduced viscosity. Reduced viscosity causes better spray formation at elevated temperatures for elevated compression ratios. Least HRR for the blend is obtained at 16 CR due to the reduction in the pace of mixture formation, feeble air entrainment and inferior burning of the fuel occurring at a lower compression ratio (Muralidharan & Vasudevan, 2011).

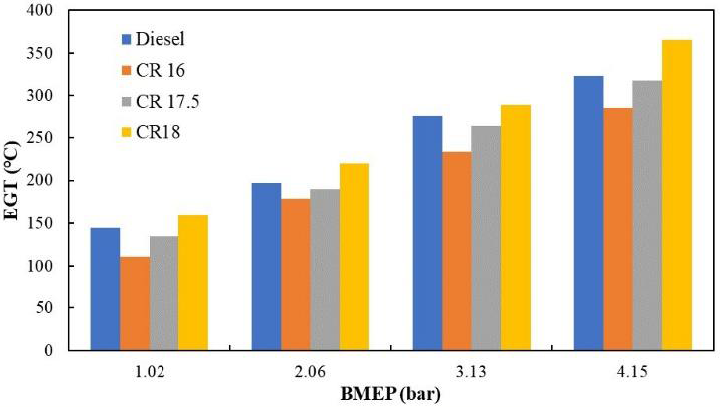

3.3.3. Exhaust gas temperature (EGT)

The qualitative analysis of the fuel combustion can be carried out by interpreting the EGT. The variation in the EGT of all the test fuels and the influence of CR is clearly depicted in Fig. 8. For individual fuel blends, the EGT increased with respect to load as it is a well-known fact the more fuel is burnt at high loads. At standard CR, the EGT of diesel and blend were found to be 324 and 319 °C respectively, at peak load.

The EGT value of diesel is higher than the blend at CR 17.5 owing to its higher calorific value and better combustion at standard engine conditions. Also, the water content in pyrolysis oil absorbs the heat for vaporization which in turn decreases the local flame temperature (Prakash et al., 2013). At the same loading condition, the EGT of blended fuel augmented with an increase in CR. At peak load, the EGT values of the blended fuel were recorded as 287, 319 and 367 °C for the CR of 16, 17.5 and 18 respectively. This augmentation of the EGT with respect to the CR can be attributed to enhanced atomization of fuel and augmented air temperatures that prevailed at high CR (Sharma & Murugan, 2015). It is noteworthy that the blend exhibited a nearly 43 °C hike in EGT at 18:1 CR as compared to that of neat diesel fuel operation at standard CR. These values can be correlated with that of NOx emission data of the blended fuel.

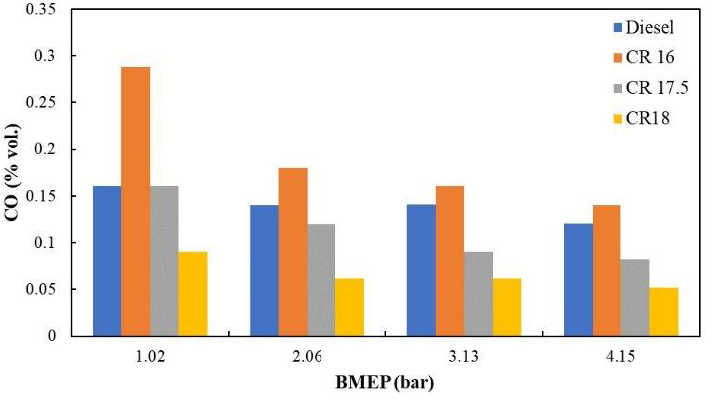

3.4.1. Carbon monoxide (CO)

Fig. 9 presents the changes of CO emissions with respect to brake mean effective pressure. It was found, the CO emission depreciated by 61% as the CR was increased from 16 to 18.

This inverse trend was observed at all loads. As the CR increases, the temperature of air molecules shoots up which shortens the ignition delay which in turn supports the formation of carbon dioxide (Srihari & Thirumalini, 2017). With the augmentation in load, the CO emission reduces for all the blends. This is because lower fuel consumption takes place at higher loads which enhances the turbulence of the fuel mixture and enhances the combustion. The CO emission of diesel and the blend at CR of 16, 17.5 and 18 are 0.12., 0.14., 0.08 and 0.05%vol respectively at peak load. At full loading, the increase in CR for the bio-oil blends decreased the CO emission by 64.28% which can be accredited to the better turbulence of fuel causing perfect combustion of fuel molecule thereby converting CO into CO2. In addition to that, the lower aromatic content and enriched oxygenated nature of pyrolysis oil enhance the oxidation of carbon atoms thereby decreasing CO emission (Kalargaris et al., 2017).

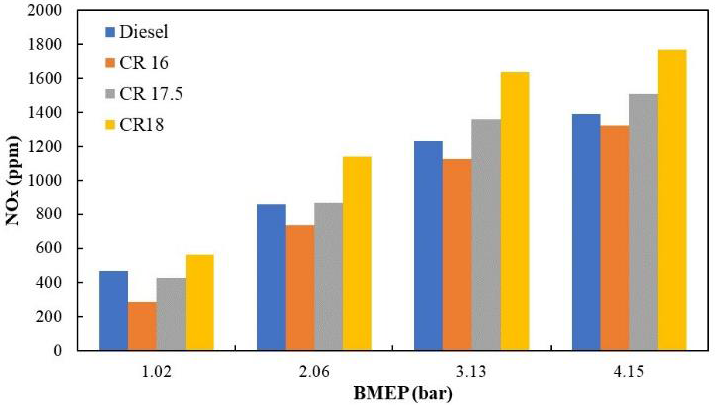

3.4.2. Nitrogen oxides (NOx)

The temperature of the gases combusted in the premixed combustion phase greatly influences the formation of NOx. Other parameters that influence the formation of NOx are oxygen content and the time interval the molecules have to react. Fig. 10 presents the NOx values in ppm for all the test fuels at different CR, at four different BMEP. The mean increase in the NOx emission as the CR is varied from 16 to 18 for the blend is 32.5 % at peak load. The NOx emission rises with augmentation in CR for the blend at every load.

Nitrogen oxides are produced by the Zeldovich mechanism which takes place at temperatures around 1500°C (Sakthivel, Ramesh, Shameer & Purnachandran, 2019). Higher compression ratios lead to elevated temperature in the combustion chamber resulting in more NOx production. At peak load, NOx emission of diesel and the blend at CR of 16, 17.5 and 18 are 1404ppm, 1332ppm, 1519ppm and 1765ppm respectively. Also, at full load, the NOx emission at a CR of 17.5 for the blend is 8 % more than diesel. This could be ascribed to the fuel-bound nitrogen and oxygen content of the blend which is referred to as fuel NOx (Rajamohan & Kasimani, 2018). It is worthwhile to note that the pattern of NOx emission follows the EGT results of the engine test. A peak in NOx magnitude of 1765 ppm was observed at CR 18 and peak load for blended fuel, exactly where the highest EGT was observed. The lower NOx magnitude was observed at lower CR owing to the diminished premixed combustion rates and heat release (Sakthivel, Ramesh, Marshal & Sadasivuni, 2019).

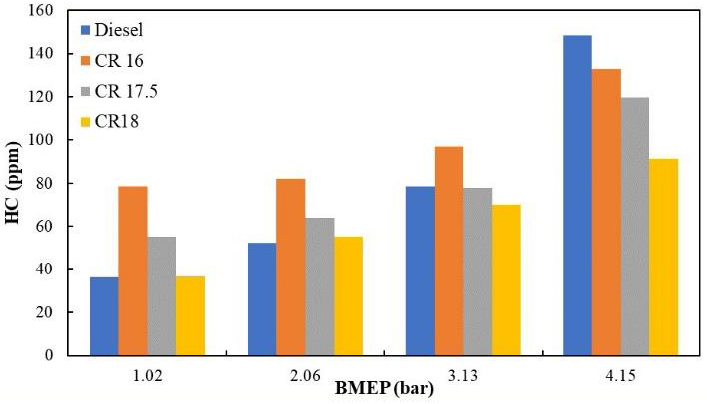

3.4.3. Unburnt hydrocarbons (HC)

HC emission depends on various conditions such as engine operating parameters, fuel properties, fuel-spray attributes and the reciprocal action the sprinkle of fuel and air exert on each other (Volli et al., 2014). HC is emission represents the fuel partially burned or completely unburned. Thus, the most important by-product signifying incomplete combustion of molecules of the fuel is the emission of hydrocarbon. The air-fuel equivalence ratio shows variation from the core to the periphery of the spray. It is high at the core and low at the periphery and this affects hydrocarbon emissions (Pundir, 2007).

Fig. 11 shows the variation of HC with BMEP. The HC emissions reduce significantly as the compression ratio increases. This can be attributed to better combustion at higher CR which diminishes the production of HC emission. Better combustion, in turn, is obtained at higher CR due to increased air density, better mixing and in-cylinder temperature. The mean reduction in HC emission as the CR is varied from 16 to 18 is 36.7%. At peak load, the HC emission for diesel and blend at CR of 16, 17.5 and 18 are 149 ppm, 132 ppm, 120 ppm and 92 ppm. This reduced HC emission at peak load can be attributed to elevated cylinder temperature which leads to a shorter delay period. This in turn provides less time for mixture movement into colder ends of the combustion chamber as well as in enhanced conversion rate of HC species (Vihar et al., 2017).

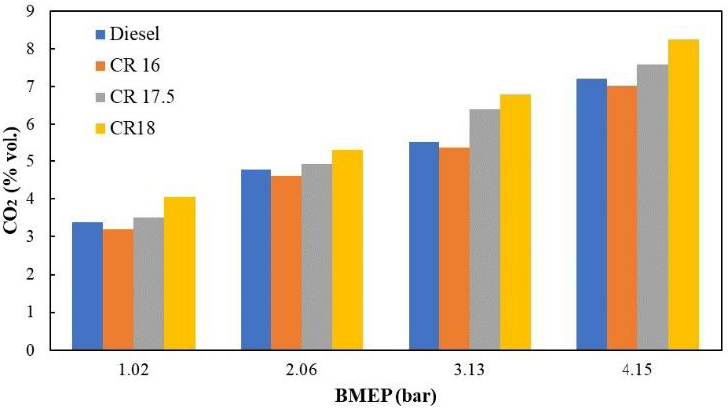

3.4.4. Carbon dioxide (CO2)

Carbon dioxide is considered the product of the complete combustion of fuel during the power stroke. Even though carbon dioxide is one of the major greenhouse gases, it is desired over other emissions due to the closed carbon cycle of biofuels. It is obvious fact that the amount of CO2 at exhaust of an engine operated with biofuel directly implies its efficiency. Fig. 12 displays the variation of carbon dioxide with BMEP.

From the results, it can be observed that the carbon dioxide emission showed a typical trade-off with CO emission which was observed by most of the researchers. At 100% load, the CO2 emission for neat diesel and blend at 16, 17.5 and 18 CR is 7.24 %vol., 7.02 %vol. 7.6 %vol. and 8.26 %vol. An average increase of 17% CO2 was noted for the blended fuel at the entire loading spectrum when the CR was increased from 16 to 18. The reason for the hike in carbon dioxide with augmenting CR and load is due to improved burning at higher CR. In addition to that, fuel bound oxygen is also a major contributor to augmented CO2 emission in the case of blended fuel usage since the excess oxygen helps in the oxidation of carbon atoms during combustion.

4. Conclusions

The engine testing attributes of the Bael pyrolysis oil blend were studied at three CRs of 16, 17.5 and 18 and the similarities and differences were drawn in contrast to that of diesel at standard CR of 17.5. The major conclusions drawn from the investigation are presented below.

At 100% load, the peak pressure inside the cylinder and the HRR for the Bael pyrolysis oil blend at 18 CR has been improved by 12.9% and 2% when compared to the blend at standard CR, and by 11.4% and 22.2% when compared to diesel at standard CR.

Regardless of the load, the BTE is found to increase with CR for the blend. The BTE acquired at 18 CR is 20% greater than diesel at standard compression ratio and 5% more than that of the blend at standard compression ratio.

The brake-specific energy consumption reduces with an increase in CR irrespective of the load. The BSEC at a CR of 18 is 16.6% less than that of diesel at standard CR and full load.

The CO and HC emissions showed a decreasing trend with augmentation of CR and load. At CR 18, the CO emission and hydrocarbon emission of the blended fuel was decreased by 58.3% and 35.2% respectively compared to diesel at standard CR.

Oxides of emission increased with CR and load for all the test fuels in the current work. The nitrogen oxide emission for the blend at 18 CR was 16% more than that of neat diesel at standard compression ratio which shows the effective combustion of fuel owing to its oxygenated nature.

Based on the obtained results it can be suggested that the BPO blend gives better results at compression ratio 18:1 in terms of engine operating attributes. Though the nitrogen oxide emission is higher at higher CR, it falls within the acceptable range. The present research provides an insight to utilize Bael pyrolysis oil in stationary engines for agricultural applications whereas the future scope of the work extends in fuel up-gradation techniques so that the present proposed fuel can be successfully used as a fuel additive in commercial transportation diesel fleets.

Conflict of interest

The authors have no conflict of interest to declare.

Financing

The authors received no specific funding for this work.

nueva página del texto (beta)

nueva página del texto (beta)