1. Introduction

This paper presents a real-life problem for the design of an opening hazardous material production and distribution network by optimizing capital expenditures (CAPEX) and operating expenses (OPEX). The problem presents a high degree of complexity, mostly because both CAPEX and OPEX play a major role in the feasibility of the venture. CAPEX includes buying machinery, acquiring permits, and investment in transport vehicles (fleet size), whereas OPEX involves a hazardous material to the customers (truck drivers and truck fuel) and the raw material costs.

The problem considers that a company has evaluated several locations on which to install the processing of a product and distribute from there to different customer’s locations. The transportation is considered as in-house, reason why the fleet size and vehicles capacities are a decision of the owners or investors of the company. The company business model requires the customers to sign a take-or-pay off contract in which it is obligated to pay for a specific amount of product independent on whether it is consumed or not. This business model allows for the planning of the whole contract period by the selection of supply stations, machinery and transport routes.

In this paper, a new version of the Multi Depot Multi Period Vehicle Routing Problem with heterogeneous fleet (MDMPVRPHF) is proposed. In this version, CAPEX are included to the MDMPVRPHF model as a set of restrictions that must be considered to design a better freight distribution network. We called this model the Multi Depot Multi Period Vehicle Routing Problem with heterogeneous fleet and management restrictions (MDMPVRPHFMR).

The MDMPVRPHF and the MDMPVRPHFMR are variants of the vehicle routing problem (VRP). The VRP is introduced by Dantzig and Ramser (1959). It is the generalization of the Traveling Salesman Problem (TSP) presented by Flood (1956). The classic VRP aims to design a network by minimizing distances, travel times or transportation costs. The network is defined on a graph

G = (V, Ɛ, C), where V = {V 0 , …, V n } is a set of vertices, Ɛ = {(V i , V j )│(V i , V j ) ϵ V 2 , i ≠ j } is the arc set; and

C = (C ij ) (Vi, Vj)ϵƐ is a cost matrix defined over Ɛ. The depot is vertex V 0 and the customers to be served are represented by the remaining vertices V (Pillac, Gendreau, Guéret, & Medaglia, 2013). The classic VRP consists in designing a network by finding a set of routes for a fleet of vehicles with the same capacity, customer´s demands are known and supplied by only one vehicle (Archetti & Speranza, 2008).

Different VRP variants have been developed. The most studied are the Capacitated VRP (CVRP), the VRP with time Windows (VRPTW), the VRP with Pick-up and Delivery (PDP), the Split Delivery Vehicle Routing Problem (SDVRP), and the Heterogeneous fleet VRP (HVRP).

In the CVRP, a set of customers have a different demand for a good and the fleet of vehicles have finite capacity (Pillac et al., 2013). The VRPTW designs routes from one depot to a set of dispersed customers who can be supplied once by only one vehicle in a time interval, every route starts and ends at the depot, the total demand transported per route (sum of the demands of all points in a route) cannot exceed the capacity of the vehicle (Braysy & Gendreau, 2005). In the PDP, a specific amount of goods must be picked-up and delivered to customers (Pillac et al., 2013). Contrary to the classical VRP, the SDVRP does not consider the restriction that costumers that costumers are supplied by only one different capacities and costs is available for the distribution of goods (Baldacci, Battarra, & Vigo, 2008).

In the literature, there are many variations of the HVRP problem with vehicles capacities constraints and with time window constraints to consider multiple depots, multiple trips to be operated by the vehicles, multiple vehicles with different capacities and other operational constraints. These HVRP variations are the Heterogeneous VRP with Fixed Costs and Vehicle Dependent Routing Costs (HVRPFD), the Heterogeneous VRP with Vehicle Dependent Routing Costs (HVRPD), the Fleet Size and Mix VRP with Fixed Costs and Vehicle Depending Routing Costs (FSMFD), the Fleet Size and Mix VRP with Vehicle Dependent Routing Costs (FSMD), the Fleet Size and Mix VRP with Fixed Costs (FSMF), and the Site-Dependent VRP (SDVRP) (Baldacci et al., 2008).

Goel and Gruhn (2008) study the VRP in real-life applications, and they find different difficulties to be considered. In real-life, the VRP must consider a heterogeneous fleet of vehicles, time window restrictions, differing travel times and costs, vehicles capacity, facility capacity, vehicle compatibility with specific orders, multiple pick-ups per order, delivery locations, service locations, orders where a vehicle can start and finish a journey at different locations, and vehicle route restrictions such as maximum sizes and weights. They include these difficulties as restrictions into the classic VRP and therefore, they formulate the General Vehicle Routing Problem (GVRP). Based on the GVRP, Mancini (2016) develops the MDMPVRPHF. In her study, Mancini explains that real-life cargo distribution problems have a high degree of complexity because of multi-dimensional vehicle capacity constraints, characteristics of the vehicles, route lengths and travel times, time windows, the compatibility between products, the compatibility between products and vehicles, the compatibility between customers and vehicles, and objective functions which consider different costs such as transportation costs, inventory costs, opportunity costs, etc.

In this article, the MDMPVRPHFMR recognizes the MDMPVRPHF restrictions and adds and proves that CAPEX transport vehicles) and OPEX (raw material cost and transportation of product to the customers such as truck drivers and truck fuel).

This article presents the application of the MDMPVRPHFMR to a real-life problem for the design of an opening liquefied natural gas (LNG) distribution network for a planning time horizon. In this study case, the CAPEX and OPEX information of a real company is used to design its distribution network prior to establishing a contract with the client. The model simultaneously optimizes location allocation, production capacity and vehicle routing decisions. To solve the problem, we present optimal solutions for different random variables small instances using the optimization software CPLEX from IBM. The customers’ demands and the distances between nodes (suppliers and customers) have been generated using Mersenne Twister which is a random number generator. These values are different for each instance and they are presented in Appendix A.

The paper is organized as follows. In Section 2, the MDMPVRPHF and the MDMPVRPHFMR problems are described and the mixed integer linear programming models are presented. In Section 3, the study case is presented together with the computing results of the application of the MDMPVRPHF and the MDMPVRPHFMR models. Section 4 presents the aleatory instances used to test the MDMPVRPHF and the MDMPVRPHFMR models and their computing results. Finally, conclusions and references are included.

2. MDMPVRPHFMR problem description and mathematical

2.1 MDMPVRPHFMR problem description

The company’s business model is to deliver a steady, guaranteed and contractual supply of natural gas to its customers. To produce LNG, a liquefaction plant and access to a natural gas pipeline are needed. Since the natural gas pipeline network in Mexico is not vast, there are industrial plants that do not have access to natural gas via pipeline, and their natural gas consumption must be delivered by truck as compressed natural gas (CNG) or LNG. A typical supply chain of LNG consists of a liquefaction plant that is connected to the natural gas pipeline, terrestrial transport of the LNG via trucks and a vaporization plant that converts the LNG into natural gas to be consumed as fuel in the client’s installations. Storage may be added in the liquefaction plant and in the customer’s plant as buffer to account for transport eventualities.

When a customer quotes a LNG contractual supply, the company has to determine the nearest feasible connections to the natural gas pipeline in which liquefaction plan must be installed and the possible terrestrial routes to deliver the LNG to the client. The investment required for LNG plants is high, therefore a long-term supply take-or-pay contract is signed between the customer and the company, in which the customer is obligated to pay for a specific amount of product independent on whether it is consumed or not. This long-term contract requires the company to consider and minimize the transportation costs, since after five or seven years, the transportation costs may be greater than the initial investment.

The different feasible connections to a natural gas pipeline that the company evaluates to supply LNG to a customer, bring several variables into consideration: land cost, permit costs, natural gas (raw material) cost, and different routes to the customer plant(s). The natural gas cost within the pipelines is not fixed territory wise and therefore dependent on the location. It can be concluded that the location of the processing and distribution plant is correlated with the operation costs, and this presents a high degree of complexity.

Since CAPEX and OPEX are correlated, the model’s objective is to minimize both simultaneously. The decisions of the MDMPVRPHFMR problem are to locate a set of supply stations, allocate supply stations to customers, select the distribution routes, manage the fleet, and select the machinery in the supply stations. The aim is to meet customer demand by designing an optimal network for the company for a planning horizon at minimum total cost.

The MDMPVRPHFMR requires solving investment in infrastructure and transport decisions. These former decisions are long-term or strategic decisions (Miranda & Garrido, 2004). The investment in infrastructure decisions are: location of supply stations through time and buying machines for production capacity. These decisions are long-term decisions that require high investment (Current, Ratick, & Revelle, 1997) because of the cost associated with property acquisition and facility construction (Owen & Daskin, 1998). The transport decisions are: the management of the fleet and its size, vehicles capacities (heterogeneous fleet), and routes selection. These decisions are long-term decisions that depend on operation costs, supply, and demand. The product transportation is considered as in-house and the allocation of supply stations to customers can change over time, normally every year (Vidal & Goetschalckx, 1997; Current et al., 1997). The MDMPVRPHFMR considers a multi-period approach and the flexibility for a vehicle to end the route at another supply station. The supply station capacity, vehicle capacity and inventory control introduced by Coelho and Laporte (2012) are restrictions also included in the MDMPVRPHFMR. Besides these restrictions, the MDMPVRPHFMR adds the cost of opening of supply stations (permits, city gate, civil), penalties for service times, machinery selection, raw material costs and fleet size.

A. Assumptions

Costumer demands are independent and location are known.

Once a supply station is located, they cannot be relocated.

The company pays a fixed location cost for opening a supply station.

The company pays a fixed cost for the natural gas in a supply station.

Once the machines are installed in a supply station, they cannot be moved to another supply station.

Vehicles capacities are known (heterogeneous fleet).

The natural gas costs remain the same throughout the optimization period in each supply station.

The CAPEX are amortized through the optimization period, which usually is equal to the customer’s contract period.

28.00 standard cubic meters of natural gas [m3] are equal to 1 million of British Thermal Units [mmBtu] of LNG which is the standard unit used in this industry, but for scientific purposes, in this paper we use cubic meters.

B. Decisions

Location, production capacity and allocation decisions: number of supply stations to locate, where to locate them, set their production capacities, and allocate customers to them.

Fleet size decisions: number of vehicles to use.

Routing decisions: What routes to operate, Vehicles must start their journey from a supply station and serve their allocated customers. Hence, the solutions include multi-period routes.

The assumptions and decisions are incorporated in a mathematical programming model presented in Section D. Its notation is introduced in Section C.

C. Definition and notations

The model works with a set of nodes, a set of supply stations, a set of customers, a set of routes, and a set of vehicles.

- V = {1…v} is the set of homogenous vehicles

- K = {1…k} is the set of routes

- I = {1…i} is the set of supply stations

- J = {1…j} is the set of customers

- M = {1…m} is the set of machines

-

Therefore, the total number of nodes is n + m, where and the maximum number of routes for all vehicles is

1) Variables

The Boolean variables are:

- |

[-] |

- |

[-] |

- |

[-] |

- |

[-] |

- |

[-] |

- |

[-] |

The integer variables are:

The continuous variables are:

- |

[m3] |

- CC

i

is the required production capacity for |

[m3/h] |

- |

[h] |

- |

[-] |

2) Parameters

The parameters are:

- α the maximum route duration |

[h] |

- s the vehicles average speed |

[km⁄h] |

- Θ the planning time horizon is the time per day available to operate |

[h] |

- Q

j

daily demand per location |

[m3] |

- C

v

the transport capacity per vehicle |

[m3] |

- r

ij

the distance matrix, with |

[km] |

- μ

v

the cost of usage per vehicle |

[$⁄km] |

- ρ

i

the cost of opening a supply station |

[$⁄day] |

- |

[$⁄m3] |

- p

m

the cost of machine |

[$⁄day] |

- c

m

the production capacity of machine |

[m3⁄day] |

- δ

j

the time to discharge/charge material from vehicles to customers |

[h] |

- γ a penalty cost in visit times |

[$] |

- β the cost of renting/buying the vehicle |

[$⁄day] |

- Num

j

the number of days in contract with customer |

[days] |

- fc

j

the fuel consumed by customer |

[$/m3] |

- margin

j

the company´s margin for supplying customer |

[$/m3] |

3) Costs and Price definitions

- CAPEX is the company capital expenditures |

[$/day] |

- OPEX is the company operating expenses |

[$/day] |

- TRA is company the daily transport costs |

[$/day] |

- VEH is the company the daily vehicle rent costs |

[$/day] |

- PEN is the company daily cost for customer time services |

[$/day] |

- RAW is the company daily raw material costs |

[$/day] |

- INV is the company daily cost for opening a supply station |

[$/day] |

- MCH is the company daily machines costs in the supply stations |

[$/day] |

- S j is the company fuel price to customer j ∈ J |

[$/m3] |

The cost of opening a supply station

D. Mixed Integer Programming model (MIP)

The main objective of a LNG distribution company is to maximize its utilities by offering different fuel price to its customers depending on the number of days in contract, the amount of fuel consumed, and the company´s margin. The fuel price (S

j

) to the customer

The CAPEX and OPEX are considered daily costs and then multiplied by the total number of days of the optimization period. The daily costs are expressed as a CAPEX and OPEX in Equation (2).

The OPEX costs are TRA, VEH, PEN, and RAW, and the CAPEX costs are INV and MCH. The TRA, VEH, PEN, and RAW are daily costs throughout the contract period. The INV and MCH costs are paid at the beginning of the contract and must be divided by the planning time horizon. To optimize all the costs simultaneously, the model is set to optimize per day, therefore the INV and MCH costs are amortized along the contract period and considered as daily payment. By substituting the CAPEX and OPEX costs, Equation (2) becomes:

Since Num

j

,

1) Objective function

In this paper, we propose to modify the MDMPVRPHF model objective function to consider CAPEX and OPEX. In this paper, we propose two modifications to the MDMPVRPHF to include management restrictions. The first modification considers TRA, VEH, PEN, RAX, INV, and MCH costs, we called this model the MDMPVRPHFMR model because it includes management restrictions considering production. The second modification only considers TRA, VEH, PEN, and INV costs, we called this model the MDMPVRPHFMRWP model because it includes management restrictions without considering production.

The MDMPVRPHFMR model aims to minimize the TRA, VEH, PEN, RAX, INV, and MCH costs, hence achieving a lower fuel price (

The objective function first term is the daily TRA. The second term is the daily VEH. The third term is the penalty cost PEN in time spent visiting customers. The fourth term is the daily raw material costs RAW. The fifth term is the daily amortization of the opening costs INV. The last term is the daily amortization of the machine cost MCH.

The MDMPVRPHFMRWP model aims to minimize the TRA, VEH, PEN, and INV costs. The objective function for the MDMPVRPHFMRWP model is shown in Equation (4b).

Finally, the MDMPVRPHF model proposed by Mancini (2016) aims to minimizes only the TRA costs. The objective function for the MDMPVRPHF model is shown in Equation (4c).

2) Mixed Integer Programming model (MIPM)

The mathematical formulation is as follows:

s.t.

Constraints (5) and (6) ensure that a customer is only visited on a route if it is assigned to that route. Constraint (7) allows the vehicle to return to the supply station from which it departed. Constraint (8) implies that the arcs leaving a supply station may be used only if the vehicle

3. Study case

In this Section, a real-life study case is presented to evaluate the performance of the proposed MDMPVRPHFMR model against the performance of the MDMPVRPHFMRWP model and the MDMPVRPHF model. For the real-life study case, the names of the locations are confidential and therefore not shown.

In this study case, the currency is USD and the input data is as follows: a contract period of 5 years, the maximum route travelling time

The cost of opening the supply stations are shown in Table 1. This costs correspond to the legal paperwork and a physical installations needed to connect the station to a natural gas supply, which is the raw material. In the case of Supply Station 2 (SS_2), there is no cost because the client already has a connection to the natural gas pipe line. The supply station opening cost

Table 2 shows the distance between nodes or between supply stations and customers in km. Where Customer 1 (C_1), Customer 2 (C_2) and Customer 3 (C_3) are three demand nodes for the same customer and SS_1, SS_2 and SS_3 are the three possible supplier stations.

The total amount of fuel consumed by the three demand nodes (C_1, C_2 and C_3) for a 5-year contract period is 412,836,900 [m3].

The customer demand nodes are shown in Table 3.

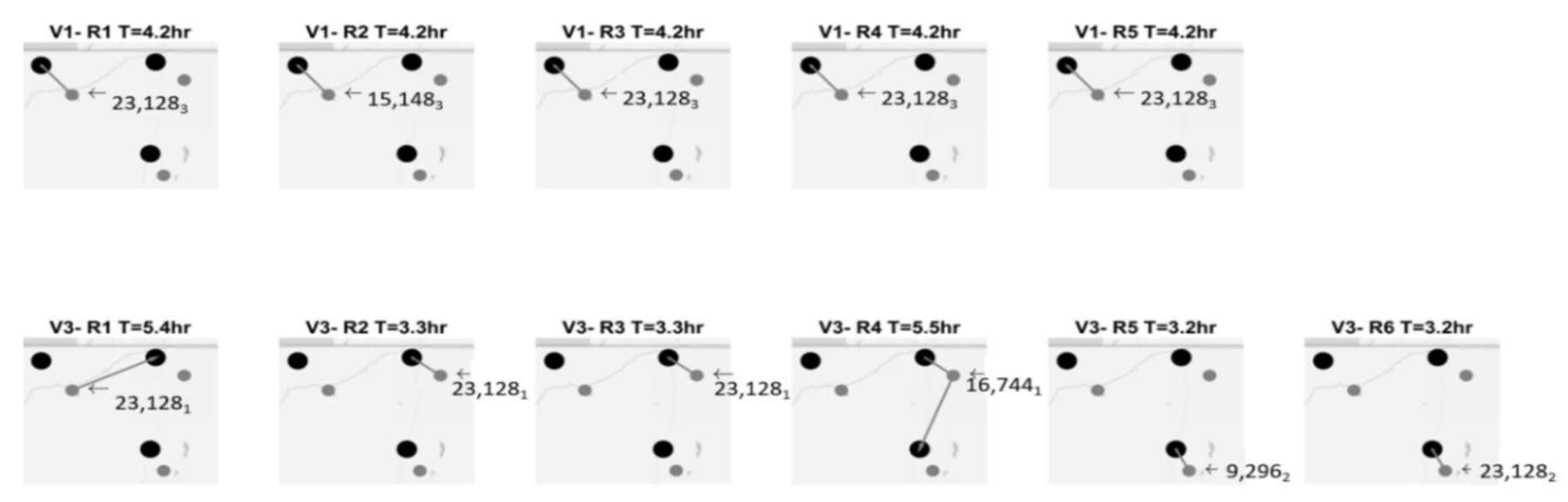

Fig. 1 shows the results for the application of the MDMPVRFHF model. In Fig. 1, Fig. 2 and Fig. 3, the dark circles indicate supply stations that are not part of the solution, the big dark dots indicate the supply stations that are part of the solution, the little light dots indicate the customer locations and the medium size dots indicate the customer locations where LNG is delivered. Each row corresponds to a vehicle

The production needed in SS_1, SS_2 and SS_3 to satisfy the customer demands at C_1, C_2 and C_3 are shown in Table 4.

The transport routes using the MDMPVRFHF model are shown in Fig. 1. Vehicle 1 (V1) operates five routes per day and vehicle 2 (V2) operates six routes per day.

Although, in the MDMPVRFHF model only TRA and VEH are minimized, all CAPEX and OPEX costs are considered for the calculation of the customers fuel priceas shown in Table 5.

Table 5. Case study costs using objective function the MDMPVRFHF model.

| Cost | Total Cost [$] | Unitary Cost [$/m3] |

|---|---|---|

| TRA | 1,041,200.00 | 0.00250 |

| VEH | 557,110.00 | 0.00143 |

| RAW | 51,605,000.00 | 0.12500 |

| INV | 1,000,000.00 | 0.00250 |

| MCH | 48,085,000.00 | 0.11643 |

| Total: | 0.24786 |

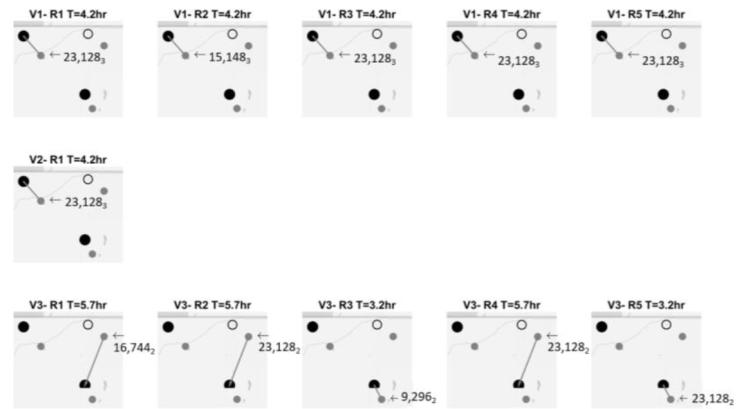

The transport routes using the MDMPVRFHFMRWP model are shown in Fig. 2. Vehicle 1 (V1) operates five routes per day, vehicle 2 (V2) operates one route per day, and vehicle 3 (V3) operates five routes per day. The production needed in SS_2 and SS_3 to satisfy the customer demands at C_1, C_2 and C_3 are shown in Table 6. The results indicate that SS_1 is not required to operate, therefore there are no opening costs for this station.

Table 7 shows all the costs considered for the customer’s fare when using the MDMPVRFHFMRWP model. By comparing the total cost per m3 of LNG from Table 5 and Table 7, it is possible to conclude that the total cost is reduced from $0.24786 to $0.23893 USD. The results demonstrate that the MDMPVRFHFMRWP model achieves lower costs than the MDMPVRFHF model.

Table 7. Case study costs using objective function the MDMPVRFHFMRWP model.

| Cost | Total Cost [$] | Unitary Cost [$/m3] |

|---|---|---|

| TRA | 1,267,900.00 | 0.00321 |

| VEH | 835,660.00 | 0.00214 |

| RAW | 51,605,000.00 | 0.12500 |

| INV | 500,000.00 | 0.00107 |

| MCH | 44,387,000.00 | 0.10750 |

| Total: | 0.23893 |

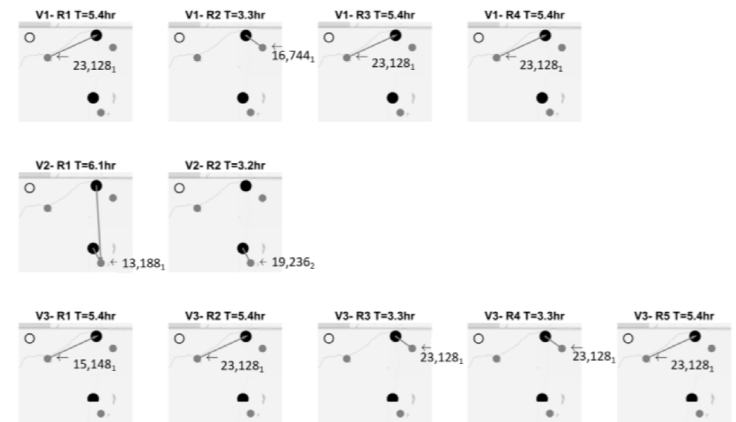

Finally, the transport routes using the MDMPVRFHFMR model are shown in Fig. 3. Vehicle 1 (V1) operates four routes per day, vehicle 2 (V2) operates two routes per day, and vehicle 3 (V3) operates five routes per day. The production needed in SS_1 and SS_2 to satisfy the customer demands at C_1, C_2 and C_3 are shown in Table 8. The results indicate that SS_3 is not required to operate, therefore there are no opening costs for this station.

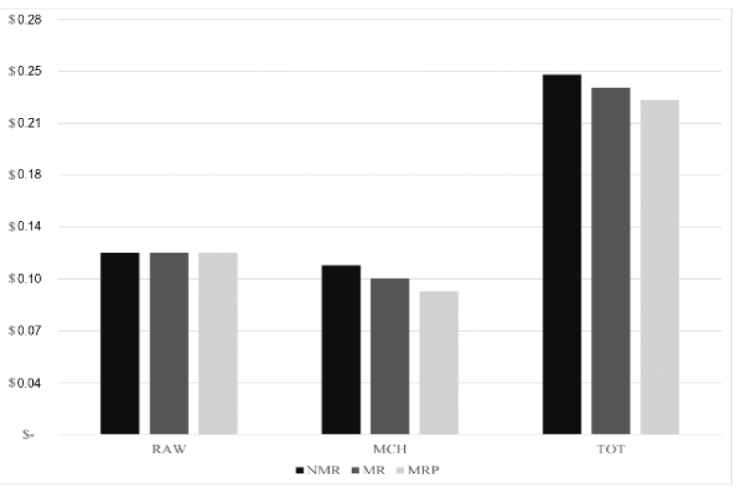

Table 9 shows all the costs considered for the customer’s fare when using the MDMPVRFHFMR model. By comparing the total cost per m3 of LNG from Table 5 ($0.24786), Table 7 ($0.23893), and Table 9 ($0.23), it is possible to conclude that the minimum total cost, and hence the minimum fuel price (

Table 9. Case study costs using objective function the MDMPVRFHFMR model.

| Cost | Total Cost[$] | Unitary Cost[$/m3] |

|---|---|---|

| TRA | 1,383,100.00 | 0.00321 |

| VEH | 835,660.00 | 0.00214 |

| RAW | 51,605,000.00 | 0.12500 |

| INV | 500,000.00 | 0.00107 |

| MCH | 40,688,000.00 | 0.09857 |

| Total: | 0.23000 |

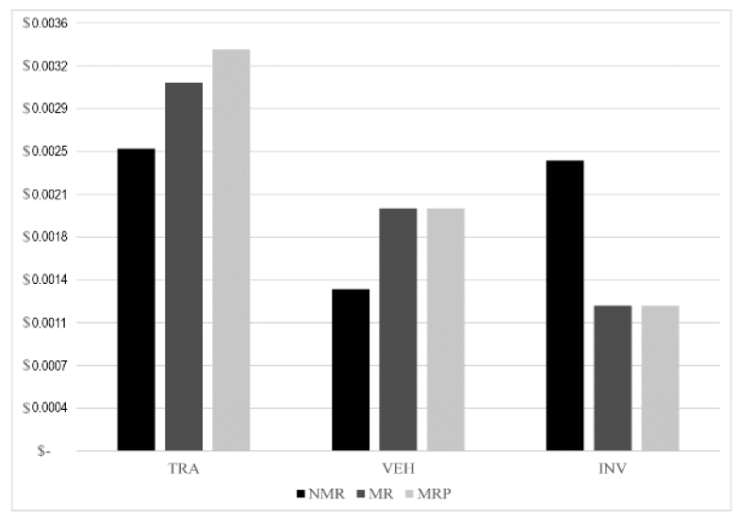

The best fuel price for the customer (S j ) is obtained when using the proposed MDMPVRFHFMR model. It is important to notice that the machine utilization increases when we consider the MCH. The unitary costs TRA, VEH and INV for the three models are compared in Fig. 4. The unitary costs RAW, MCH and the sum of all costs are compared in Fig. 5 for the three models under study.

Although OPEX increases when all costs are minimized, the MCH costs decreases and therefore the total cost is minimized and the best fuel price for the customer (S j ) is obtained.

4. Computational Results

In this section, we test the performance of the MDMPVRPHF model, the MDMPVRPHFMRWP model, and the MDMPVRPHFMR model. These tests study how suitable the models are to solve small and medium instances. A description of the instances used in the computational study is given in Appendix A. Table 10 shows the computation results for each instance tested.

Table 10. Computation results for each instance.

| MDMPVRPHF | MDMPVRPHFMRWP | MDMPVRPHFMR | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Instance | UB | LB | Gap (%) | CPU (s) | $/m3 | UB | LB | Gap (%) | CPU (s) | $/m3 | UB | LB | Gap (%) | CPU (s) | $/m3 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

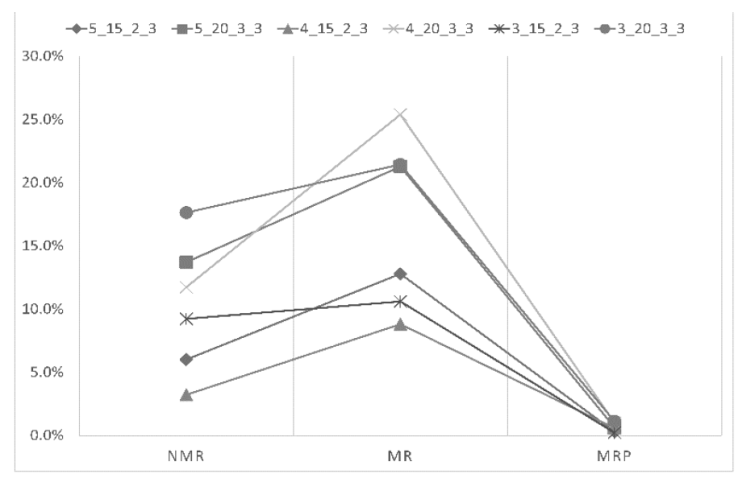

Fig. 6 shows the relative gap between the upper and lower bounds. Here, it is possible to conclude that the MDMPVRPHFMR model achieves the lowest relative gap in the same amount of computing time. For solving the MDMPVRPHFMRWP, the relative gap increases probably because the MDMPVRPHF does not narrow the possible best solutions. In the case of the MDMPVRPHFMR model, OPEX and CAPEX narrows the feasible solutions region.

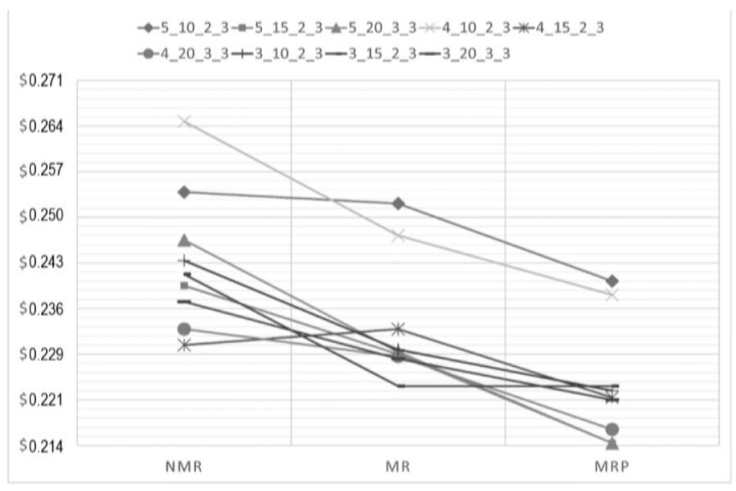

Fig. 7 shows the LNG fuel prices with the MDMPVRPHF model, the MDMPVRPHFMRWP model and the MDMPVRPHFMR model. The LNG fuel price are minimized for all instances when using the MDMPVRPHFMR model. Therefore, we can conclude that companies must consider CAPEX and OPEX for designing their supply chain networks when the contract period is fixed between the supplier and the customer.

5. Conclusions and Future Work

The Multi Depot Multi Period Vehicle Routing Problem with heterogeneous fleet and management restrictions (MDMPVRPHFMR) has been introduced and formulated in this paper. This is a modification of Mancini (2016) Multi Depot Multi Period Vehicle Routing Problem with heterogeneous fleet (MDMPVRPHF) to consider capital expenditures and operating expenses (MDMPVRPHFMR). In the MDMPVRPHFMR, the goal is to carry out delivery operations at the minimum costs by considering transport costs, vehicle rent costs, time services, raw material, investments, and machine costs. In this paper, we test the proposed MDMPVRPHFMR model and the MDMPVRPHF model in a real case scenario and by solving different instances with random parameters to test the effectiveness and efficacy of these models. The results allows to compare the performance of the proposed MDMPVRPHFMR model with the results obtained using the model proposed by Mancini (2016) or MDMPVRPHF model. By comparing results, it is possible to conclude that the minimum total cost, and hence the minimum fuel price (

The major contribution of this paper is the proposition of a model capable of minimizing CAPEX and OPEX at the same time with the aim of designing a LNG supply chain network considering must of the variables presented in a real company scenario. By considering more variables and having more real restrictions the feasible solutions region is narrowed and therefore the relative gap between the upper and lower bound is reduced. Finally, it is possible to conclude that companies must consider CAPEX and OPEX for designing real supply chain networks when the contract period is fixed between the supplier and the customer.

As future work, a Periodic Multi Period Vehicle Routing Problem with heterogeneous fleet and management restrictions can be developed for companies that require periodic deliveries. Such a model can be an extension of the periodic vehicle routing problem (PVRP) and the MDMPVRPHFMR.

nueva página del texto (beta)

nueva página del texto (beta)