Introduction

The most important tissue for plant chemical analysis is the leaf, as it directly represents the plant nutritional status and indirectly the soil fertility. Since plant nutritional status and yield are correlated factors, wrong chemical analysis can economically affect the agriculture returns. Previous to chemical analysis, samples should be properly prepared (washed, dried, and stored) in order to avoid degradation and change of nutrient content, which consequently will contribute to an accurate chemical determination (Prado, 2008).

Drying is the most time-consuming procedure on foliar chemical analysis, which can be done through forced air circulation oven or lyophilization (freeze-drying) (Pastorini et al., 2002). In the lyophilization procedure most biochemical properties of the tissue are preserved, but the equipment required is expensive and the process is time-consuming. Whereas, the drying with forced air circulation oven is a simple procedure, but even widely used, it is also time-consuming and results in changing of biochemical properties of plant tissue (Marur and Sodek, 1995). According to Marur and Sodek (1995) there is also an alternative method for drying plant material using microwave oven, which has as advantage lower biochemistry changing of samples and faster drying. However, depending on the duration of drying, it is possible to lose carbohydrates and other volatiles substances through sample’s respiration.

Dry matter and nutrient content of plants, such as fruit trees (Marcante et al., 2010), lettuce (Lactuca sativa L.) (Borges et al., 2011), sugarcane (Saccharum spp.), brachiaria (Brachiaria spp.) (Silva et al., 2011), coffee (Coffea arabica L.), mango (Mangifera indica L.), blackberry (Rubus sp.) (Dias et al., 2011) and citrus (Citrus sinensis) (Rocha et al., 2011) were similar when dried with microwave oven and with forced air circulation oven. However, further studies are important to verify the overall efficacy of this alternative procedure, since plant tissues have different morphologic characteristics, water content, and nutrient content that may alter the results.

The required time for leaf samples drying in microwave oven is 25 min, whereas oven drying takes 72 h or more, depending on plant material, water content, and temperature (Lacerda et al., 2009). The advantage in reducing the duration of sample drying is faster foliar nutritional analysis, which allows in season deficiency diagnosis and possible changes of fertilization management. Nevertheless, studies are needed regarding efficacy of this alternative drying for leaves of rubber trees and eucalyptus.

In order to enable frequent use of foliar chemical analysis after microwave drying, the hypothesis that this alternative drying method does not affect the nutrient content of leaves and the interpretation of the results compared to oven-drying procedure should be tested. Therefore, the objective of this study was evaluate the effect of microwave oven drying of eucalyptus and rubber trees leaves on dry matter and macronutrient content in comparison to oven drying.

Materials and Methods

Experiment location

The study was established in laboratory conditions at the Department of Soils and Fertilizers of Universidade Estadual Paulista “Julio de Mesquita Filho”, UNESP, Jaboticabal-SP-Brazil. Two experiments were set: one using leaf samples of rubber trees (Hevea brasiliensis Muell. Arg.), clone RRIM 600 (Rubber Research Institute of Malaysia 600), and leaf samples of eucalyptus (Corymbia citriodora (Hook.)). For both experiments, leaves were collected at the Experimental Area of Agriculture Science and Veterinary, Universidade Estadual Paulista, Campus Jaboticabal - São Paulo.

Treatments and plant material management

The treatments were two drying methods, the conventional oven with forced air circulation and the microwave oven (MWO). A completely randomized design was used with 10 repetitions.

Leaves were collected from the terminal branches at the lower third part of rubber trees, whereas branches directed to the north side, as determined by Gonçalves et al. (1997), were used for leaf samples of eucalyptus trees. Two leaves were selected per spot, totalizing 200 leaves per plant, and only one tree per specie was sampled.

For each crop, samples were separated into 20 groups containing 10 leaves. The material was washed with run water, neutral detergent solution (0.1 %), hydrochloric acid solution (0.3 %), and deionized water, according to Prado (2008). Before submitting it to the respective drying method treatment, samples were left to dry in absorbent paper.

The oven with forced air circulation (68 L capacity) was set to 65-70 °C and samples were kept inside it for 72 h, till constant dry mass (Prado, 2008). The microwave drying followed Lacerda et al. (2009) procedure, wherein each sample was dried for three cycles of 5 min, one cycle of 3 min, and one cycle of 2 min.

In order to avoid fixation on container surface, leaf material was detached with a spatula between each cycle. A beaker with 150 mL of water was also placed inside the MWO to increase the moisture and avoid burning of samples, as reported by Undersander and Thiex (1993). The water container was replaced every cycle to avoid water ebullition and contact with leaf sample.

The microwave had maximum load of 5 kg, 35 L of capacity, 110 V, 13 A, 60 Hz, 900 W of power output (maximum), operation frequency of 2450 MHz, and 306 mm width, 455 mm depth, and 555 mm height.

Evaluation and statistical analysis

After drying the samples, the dry matter was determined using a precision (0.0001 g) scale. Samples were then ground with Willey grinder at 1 mm and transferred to paper bags for further macronutrients content determination, according to Bataglia et al. (1983).

The data were submitted to analysis of variance; F test and Tukey test were used to compare means (p≤0.05), using Sisvar statistical software (Ferreira, 2011).

Results and Discussion

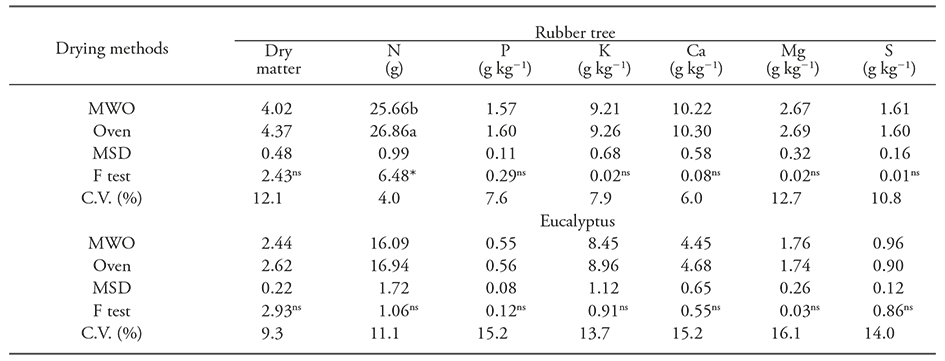

There were no differences between the drying methods on leaf nutrient content, except for N content of rubber trees. Leaves of rubber trees dried with microwave oven had lower N content than leaves dried in the common oven (Table 1). Even though difference in N content was found, both methods resulted in foliar N content bellow the proper range for the culture (N: 29 to 35 g kg-1), according to Raij and Cantarella (1997). Therefore, the methods chosen would not affect the nutritional diagnostic of rubber trees, as N application would be required regardless of the drying method.

Table 1 Dry matter and leaf macronutrient content of rubber trees and eucalyptus samples according to the drying method

MWO: Microwave oven; *p≤0.05; ns non-significant; MSD: minimum significant difference.

These results support the potential use of microwave to dry leaf samples of eucalyptus and rubber trees. Our results are similar to those reported by Marcante et al. (2010), Borges et al. (2011), Dias et al. (2011), Silva et al. (2011), and Rocha et al. (2011) who studied fruit trees, lettuce, sugarcane and brachiaria, coffee, mango, and blackberry, and citrus, respectively.

The proper range of foliar nutrient content for rubber trees, according to Raij and Cantarella (1997) is: N: 29 to 35, P: 1.6 to 2.5, K: 10 to 17, Ca: 0.7 to 0.9, Mg: 1.7 to 2.5, S: 1.8 to 2.6 g kg-1. Therefore, N, K and S foliar content were below the proper range for the culture; whereas, high content of Mg and Ca, and proper content of P was also observed.

Similar foliar nutrient content was observed for eucalyptus dried with oven and microwave oven (Table 1). Since the proper range of foliar content is: N: 13 to 18, P: 0.9 to 1.3, K: 9 to 13, Ca: 6 to 10, Mg: 3.5 to 5.0 and S: 1.5 to 2.0 g kg-1 (Gonçalves et al., 1997), lower P, K, Ca, Mg and S content and proper N content were found for eucalyptus samples.

The microwave drying method is an efficient alternative for drying leaf tissue of rubber tree and eucalyptus, as it reduces drying-time from 72 h to 30 min, results in faster chemical analysis, reduces the waiting-time for results, optimizes management decision regarding the fertilization, and probably increase yield.

Conclusions

The drying methods with forced air circulation oven and microwave oven are similar regarding the dry matter determination and macronutrient content of rubber trees and eucalyptus leaves. Therefore, microwave drying is useful as an alternative method to dry plant tissues samples aiming to its chemical analysis.

texto en

texto en